Manufacturing method of fiber full winding plastic liner composite gas cylinder

A manufacturing method and liner technology, which can be applied to other household appliances, household appliances, applications, etc., can solve problems such as affecting the service life and safety of gas cylinders, poor bonding performance, and sealing problems of metal parts to be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] 1. The present invention provides a new method for preparing a fully wound composite gas cylinder with a plastic liner.

[0044] 2. The invention provides a method for tightly combining the metal bottle mouth and the plastic liner, which solves the problems of plastic liner molding and sealing.

[0045] 3. The composite gas cylinder prepared by the method provided by the present invention solves the problem of the safety performance of the gas cylinder on the one hand, and solves the problem of low volume-to-weight ratio of the gas cylinder on the other hand.

[0046] 4. The treatment process of the outer surface of the plastic liner used in the present invention solves the problem of poor bonding between the plastic liner and the fiber composite layer.

Embodiment

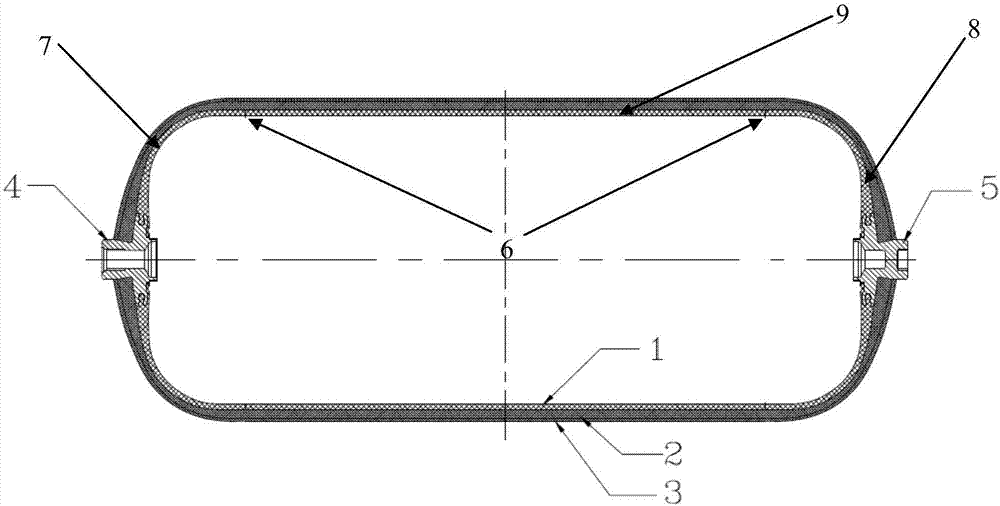

[0049] See attached Figure 1-5

[0050] Liner molding:

[0051] The material of the plastic liner 1 adopts high-density polyethylene (HDPE) produced by Borealis;

[0052] The liner structure adopts a three-stage structure, that is, the straight section of the cylinder body plus two heads, that is, the two heads 7 and 8 in the attached drawing and the straight section 9 of the cylinder body, and the straight section 9 of the cylinder body is formed by extrusion process with a diameter of 428mm pipe with a wall thickness of 10mm;

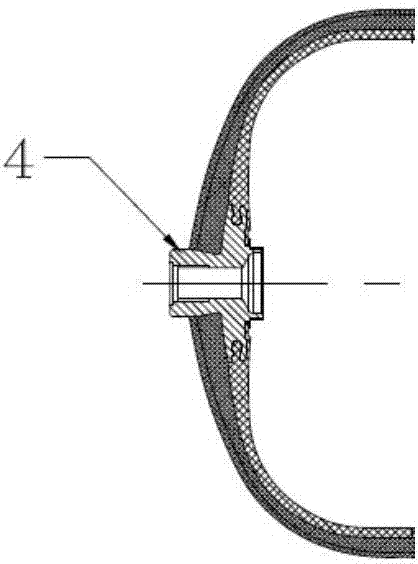

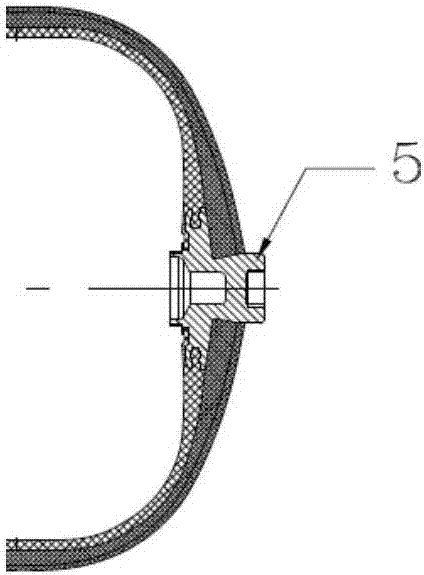

[0053] The heads 7 and 8 are composed of threaded aluminum alloy metal parts 4 and 5 and non-metallic parts. The forming process first heats the aluminum alloy joints 4 and 5 to 70-100°C, and then places them on the mold of the head , and then through the injection molding process, the aluminum alloy joint is embedded in the plastic material to form an approximately ellipsoidal head 7, 8, and it is necessary to ensure that all the dovetail grooves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com