Precision casting method of double-layer thin-wall bent pipe casting

A technology of precision casting and castings, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of low reliability, high component rejection rate, large wall thickness difference, etc., and achieve reduced production costs and reliable technical solutions , The effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

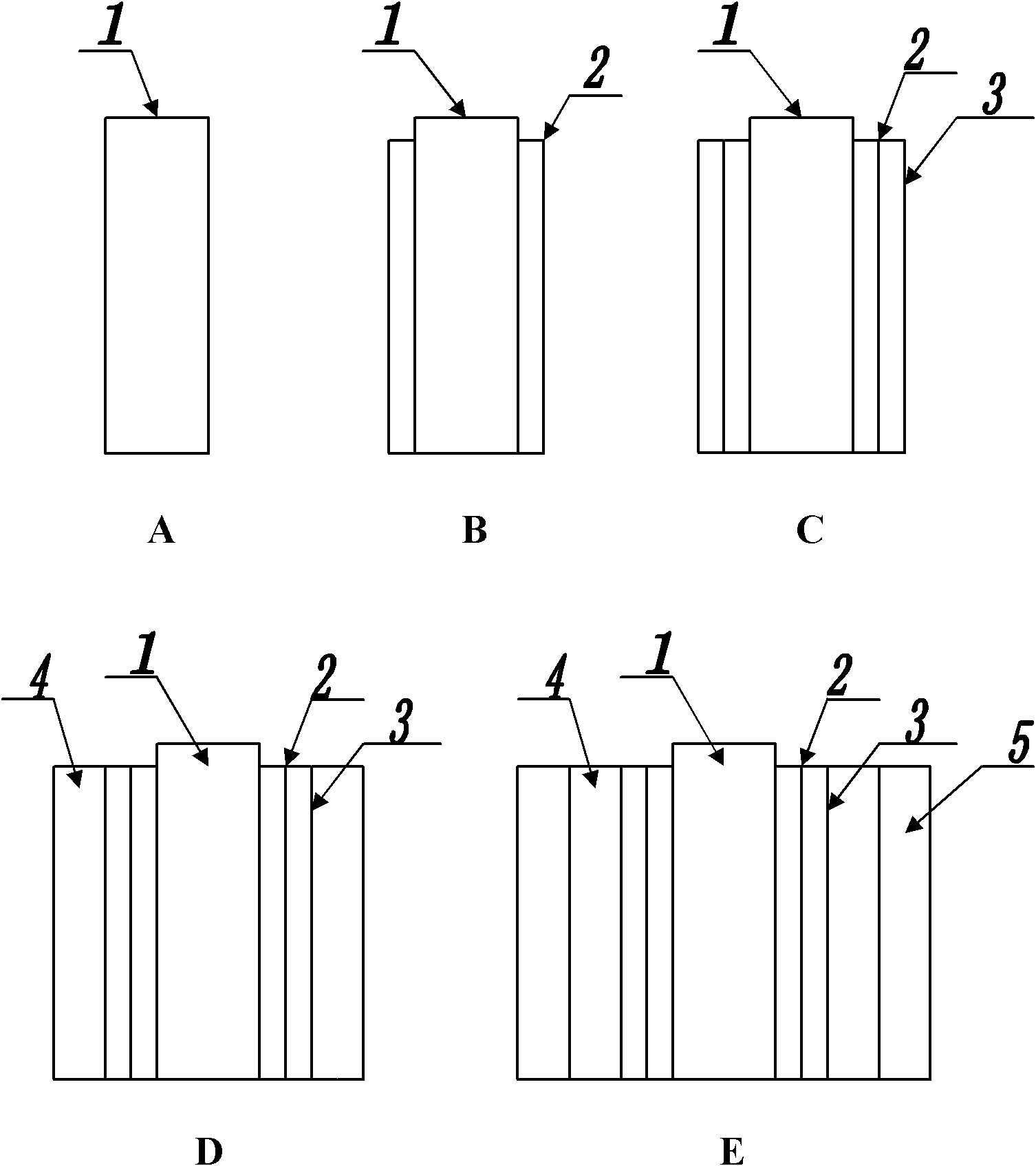

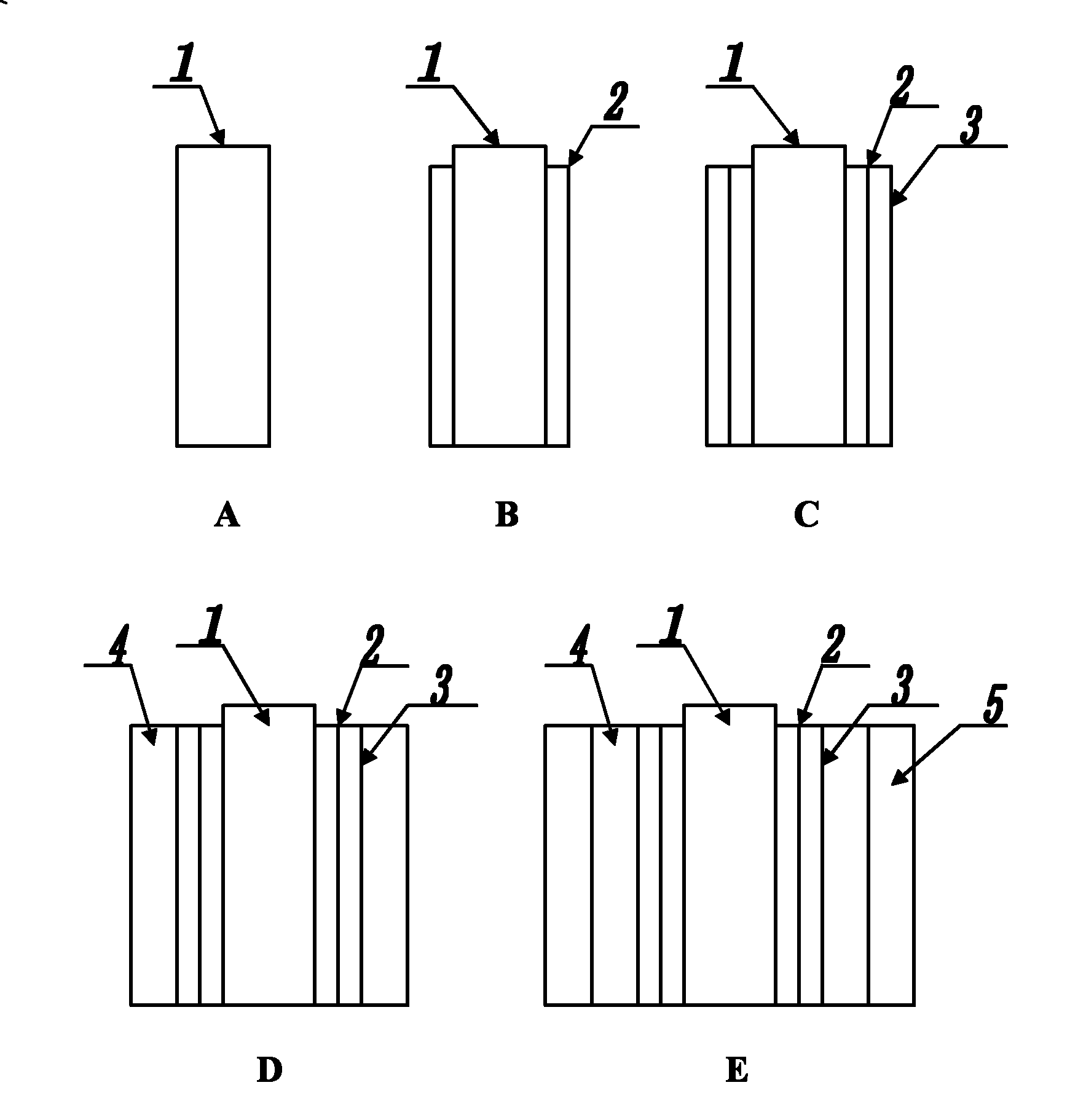

[0028] 1) see figure 1 A. Use a die head machine to press wax stick 1, injection temperature: 60-75°C, injection pressure: 0.4-0.6MPa, pressure holding time: 20min.

[0029] 2) Put the wax stick 1 into the pressed core mold 2 as the mandrel, and use a wax press machine to press the soluble carbonyl core (hereinafter referred to as 2# soluble carbonyl core), such as figure 1 Shown in B.

[0030] 3) see figure 1 C. Put the 2# soluble carbonyl core into the inner tube mold 3 as the core bone, press the inner tube wax mold with the core bone (hereinafter referred to as 3# inner tube wax mold), injection temperature: 60~75°C, Mold temperature: 20~35℃, injection pressure: 2~4MPa, holding time: 3min.

[0031] 4) Take out the 3# inner tube wax model from the mold, remove the 2# soluble carbonyl core with hydrochloric acid, and obtain the inner tube wax model with smooth surface and accurate size, as shown in Figure 3D.

[0032] 5) Make the inner pipe investment mold shell: use the...

Embodiment 2

[0040] 1) Use a die machine to press wax stick 1, injection temperature: 75°C, injection pressure: 0.4MPa, pressure holding time: 20min.

[0041] 2) Put the wax stick 1 into the pressed core mold 2 as the core bone, and use a wax press machine to press the soluble carbonyl core (hereinafter referred to as 2# soluble carbonyl core).

[0042]3) Put the 2# soluble carbonyl core into the inner tube mold 3 as the core bone, press the inner tube wax mold with the core bone (hereinafter referred to as 3# inner tube wax mold), injection temperature: 75°C, mold temperature : 35°C, injection pressure: 2MPa, holding time: 3min.

[0043] 4) Take out the 3# inner tube wax mold from the mold, remove the 2# soluble carbonyl core with hydrochloric acid, and obtain the inner tube wax mold with smooth surface and accurate size.

[0044] 5) Make the inner pipe investment mold shell: use the inner pipe wax model made in the previous step, use 70 mesh corundum sand and slurry for the first hangin...

Embodiment 3

[0052] 1) Use a die machine to press the wax stick 1, injection temperature: 60°C, injection pressure: 0.6MPa, pressure holding time: 20min.

[0053] 2) Put the wax stick 1 into the pressed core mold 2 as the core bone, and use a wax press machine to press the soluble carbonyl core (hereinafter referred to as 2# soluble carbonyl core).

[0054] 3) Put the 2# soluble carbonyl core into the inner tube mold 3 as the core bone, press the inner tube wax mold with the core bone (hereinafter referred to as 3# inner tube wax mold), injection temperature: 60°C, mold temperature : 20°C, injection pressure: 4MPa, holding time: 3min.

[0055] 4) Take out the 3# inner tube wax mold from the mold, remove the 2# soluble carbonyl core with hydrochloric acid, and obtain the inner tube wax mold with smooth surface and accurate size.

[0056] 5) Make the inner pipe investment mold shell: use the inner pipe wax model made in the previous step, use 100-mesh corundum sand and slurry for the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com