Roadbed slop vertical vibrating compacting device

A vertical vibrating and compacting device technology, which is applied in the direction of roads, roads, road repairs, etc., to achieve the effects of high work reliability, easy promotion and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

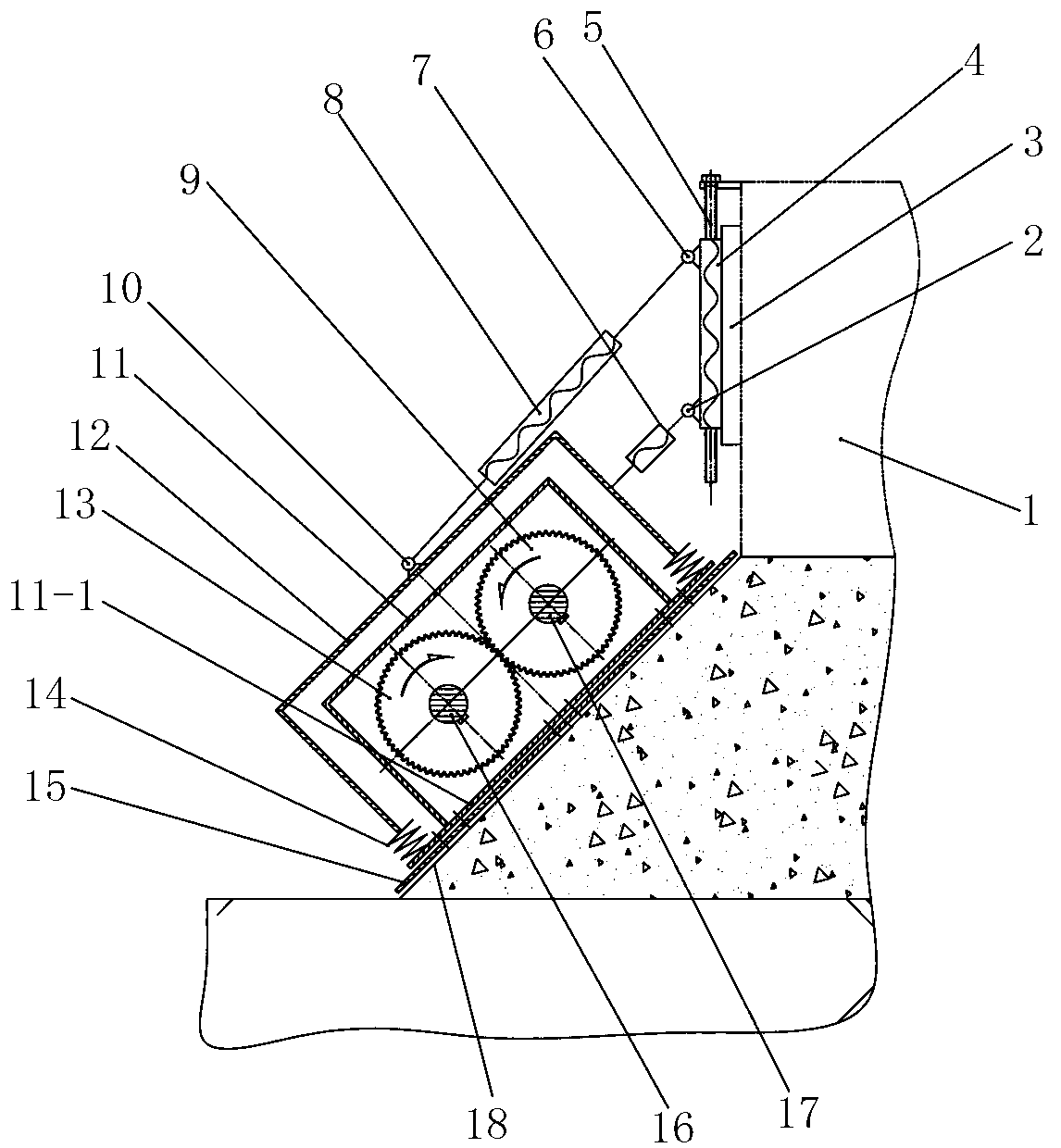

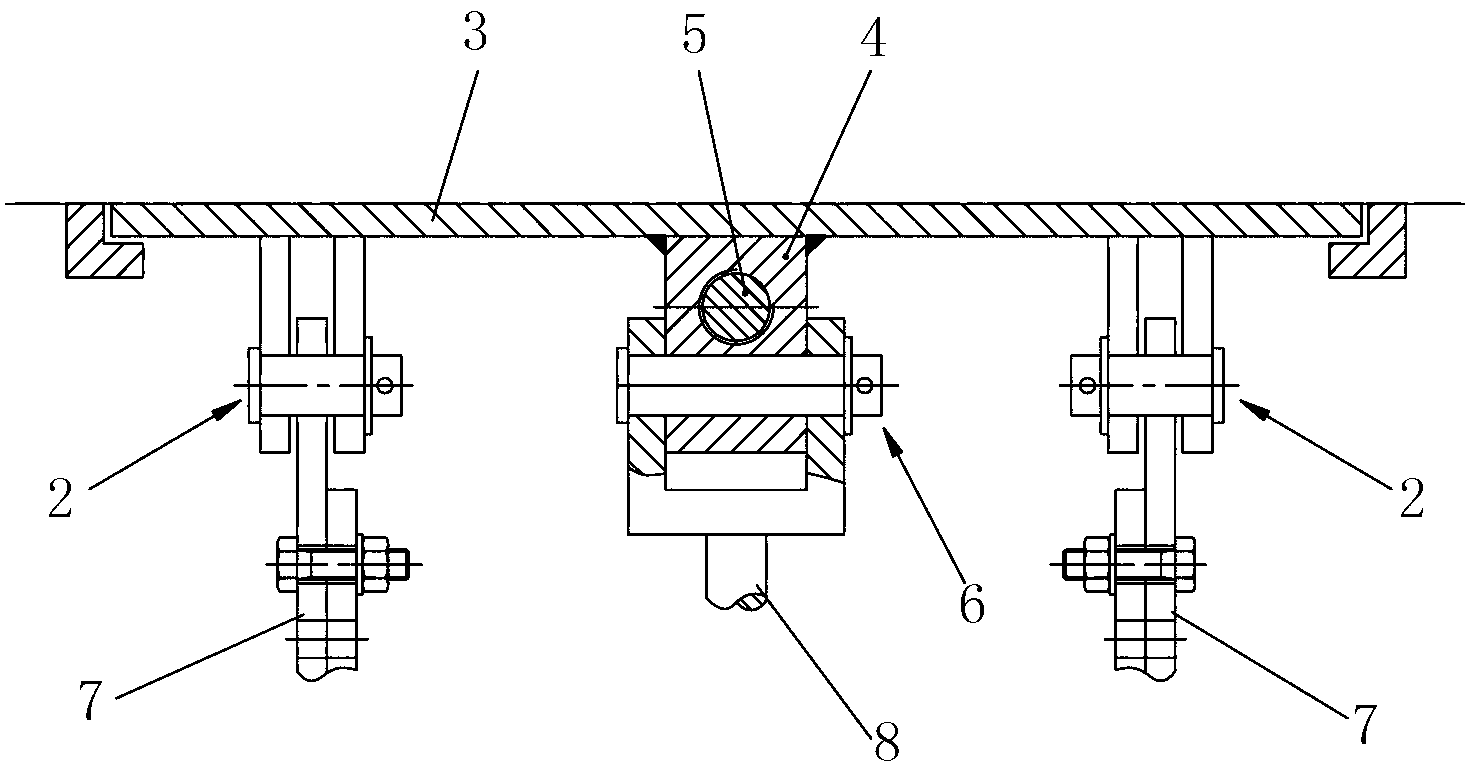

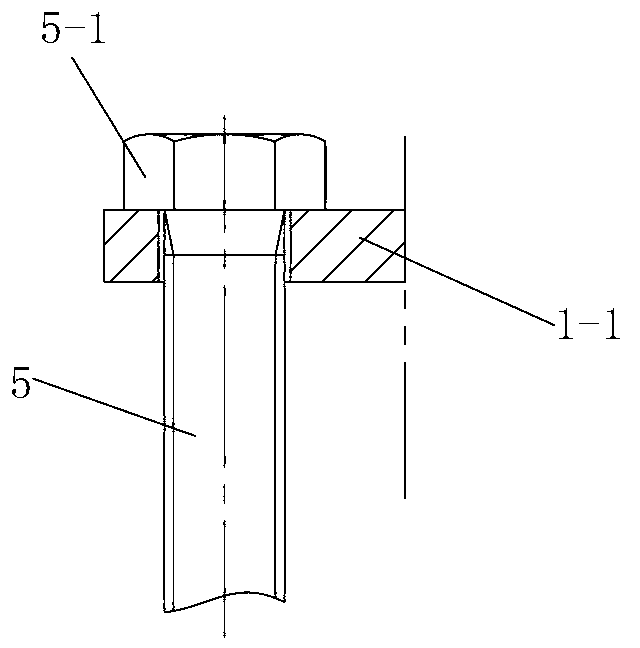

[0041] like Figure 1-Figure 6 The shown vertical vibration compacting device for roadbed slope includes a vertical vibration mechanism obliquely connected to the side wall of the working device 1, the vertical vibration mechanism includes a vibration box 11, and the vibration box 11 is rotatably connected with A rotating shaft one 17 and a rotating shaft two 16 parallel to each other, a synchronizing gear one 9 is installed on the rotating shaft one 17, and a synchronizing gear two 13 meshing with the synchronizing gear one 9 is installed on the described rotating shaft two 16, so The first eccentric block 23 is installed on the first rotating shaft 17, the second eccentric block 22 is installed on the second rotating shaft 16, and the bottom plate 11-1 of the vibration box 11 is connected with A tamping plate 15, on which a driving device 19 for driving the first rotating shaft 17 or the second rotating shaft 16 to rotate is installed.

[0042] In this embodiment, the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com