Aluminum oxide ceramic slender tube and manufacture method thereof

A technology of alumina ceramics and a production method, which is applied in the field of ceramic pipe fittings for high-voltage electrical appliances, and achieves the effect of broadening the application field and solving the problem of easy deformation during sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

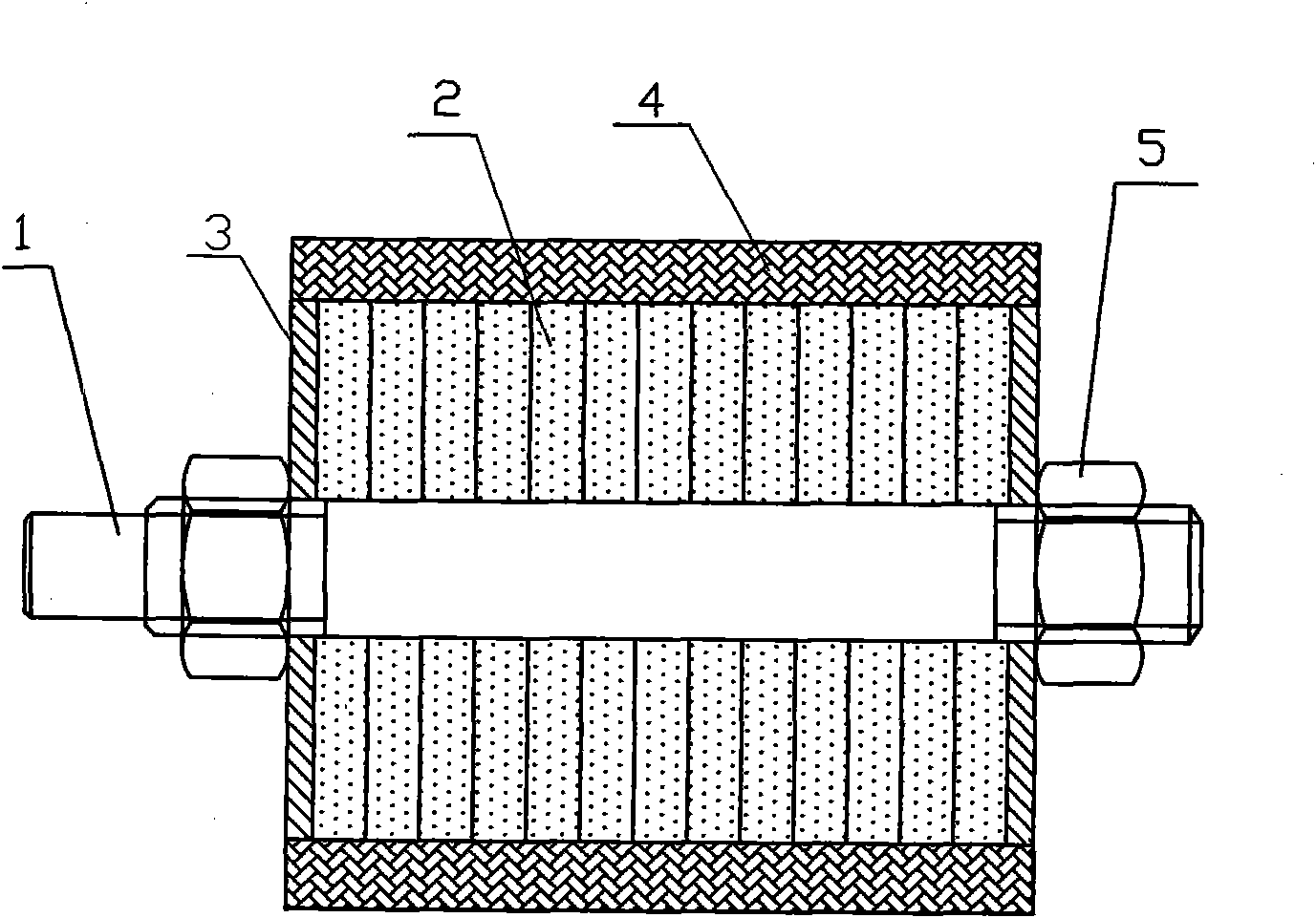

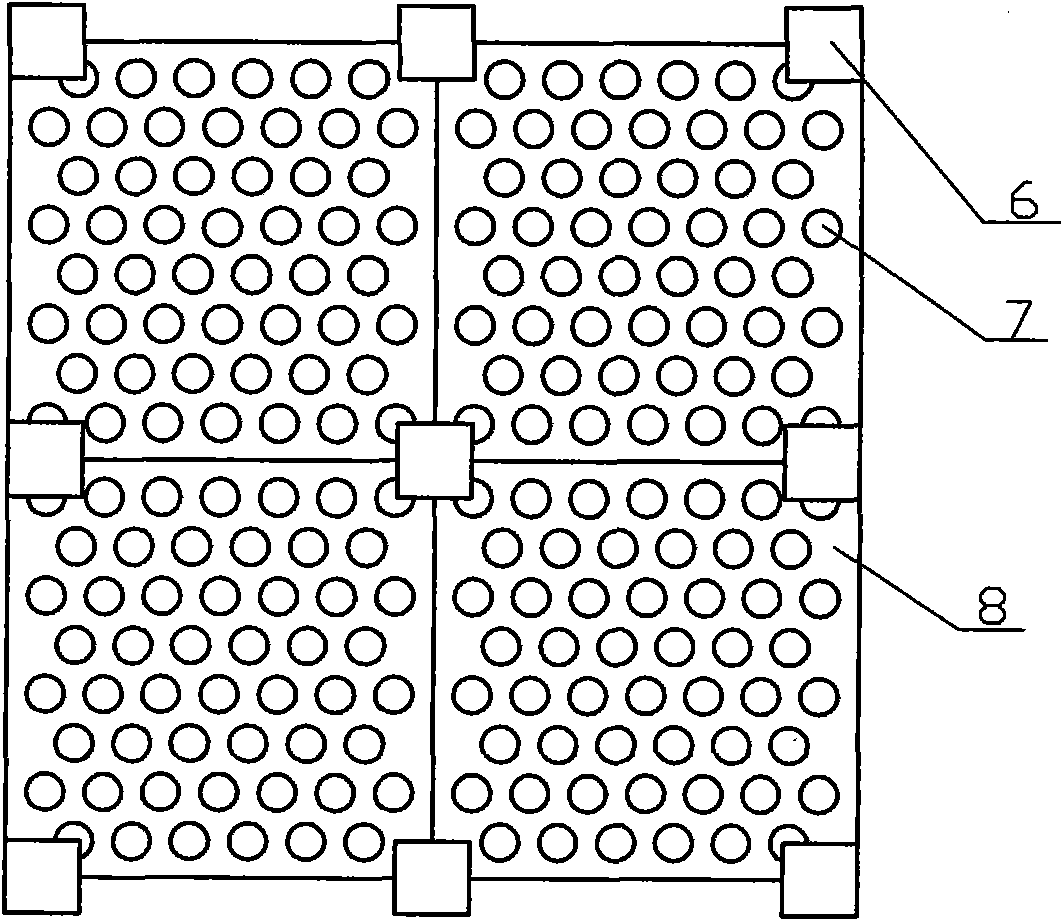

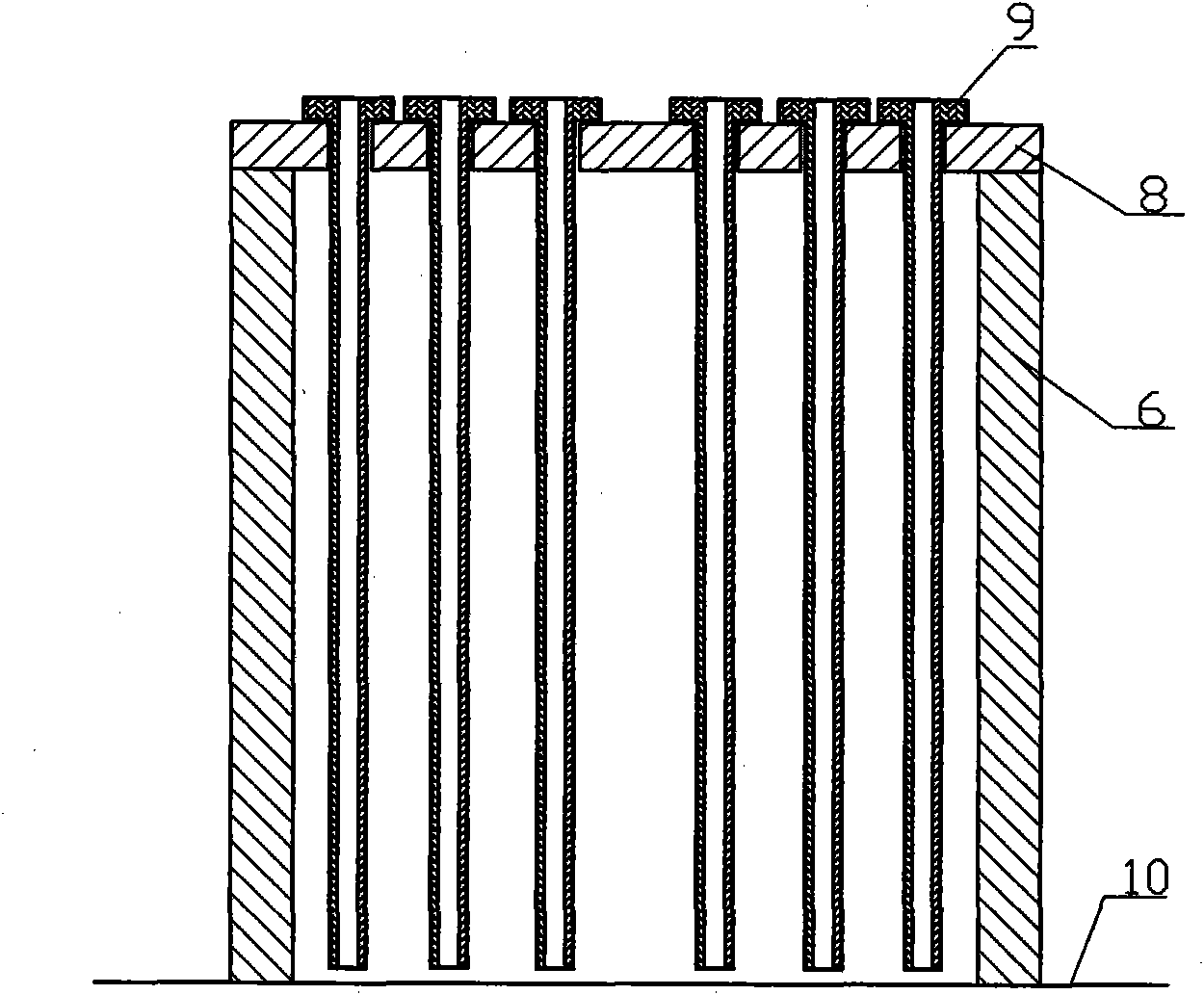

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of aluminum oxide ceramic slender tube, is made up of the raw material of following percentage by weight: α-Al 2 o 3 Powder 90%, SiO 2 1%, cooked talc 1%, CaCO 3 4%, Suzhou soil 4%, the total weight of the above raw materials is 100%, plus 0.05% polyvinyl alcohol solution accounting for the total weight of the above raw materials, 0.1% dispersant sodium hexametaphosphate, 80% water, polyvinyl alcohol solution The mass concentration is 6%.

[0028] Particle size requirements of each raw material: α-Al 2 o 3 Powder 5000-6000 mesh, SiO 2 300-325 mesh, cooked talc 300-400 mesh, CaCO 3 300-325 mesh, Suzhou soil 240-250 mesh.

[0029] A method for making an alumina ceramic slender tube, comprising the following steps:

[0030] (1) Ball milling and granulation

[0031] Add 50% α-Al to the ball mill 2 o 3 powder, add SiO 2 , cooked talc, CaCO 3 , Suzhou soil, and then add the remaining α-Al 2 o 3 Powder, water and dispersant, start ball mi...

Embodiment 2

[0047] Embodiment 2: the same place as embodiment 1 is no longer repeated, and the difference is:

[0048] Alumina ceramic slender tube raw material composition: α-Al 2 o 3 Powder 96%, SiO 2 0.5%, cooked talc 0.5%, CaCO 3 2%, Suzhou soil 1%, plus 0.1% polyvinyl alcohol solution, 0.3% sodium hexametaphosphate, and 85% water accounting for the total weight of the above-mentioned raw materials. The concentration of the polyvinyl alcohol solution is 5%.

[0049] Production method: (1) The particle size of the granulated powder obtained by ball milling and granulation is 40-80 mesh;

[0050] (2) Isostatic pressing When isostatic pressing, the core quenching temperature is 835°C;

[0051] (3) Turning the green body and clamping the blank for turning, the speed of the lathe is 380r / min;

[0052] (4) When the fired blank is hanging and fired, the firing temperature is 1680°C and the heat preservation is 3h.

Embodiment 3

[0053] Embodiment 3: The same part as Embodiment 1 is no longer repeated, and the difference is:

[0054] Alumina ceramic slender tube raw material composition: α-Al 2 o 3 Powder 91%, SiO 2 0.8%, cooked talc 0.2%, CaCO 3 3%, 5% of Suzhou soil, plus 0.06% polyvinyl alcohol solution, 0.5% sodium hexametaphosphate, and 83% water accounting for the total weight of the above raw materials. The concentration of the polyvinyl alcohol solution is 8%.

[0055] Production method: (1) The particle size of the granulated powder obtained by ball milling and granulation is 80-120 mesh;

[0056] (2) Isostatic pressing When isostatic pressing, the core quenching temperature is 825°C;

[0057] (3) Turning the green body and clamping the blank for turning, the speed of the lathe is 420r / min;

[0058] (4) When the fired blank is hanging and fired, the firing temperature is 1680°C and the heat preservation is 3.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com