Double drilling-box switching type full-automatic roofbolter

A rock bolt rig and switchable technology, which is applied in the installation of rock bolts, earthwork drilling, mining equipment, etc., can solve the problems of high labor intensity, low degree of automation, and harsh working environment, so as to reduce labor intensity and improve automation degree, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

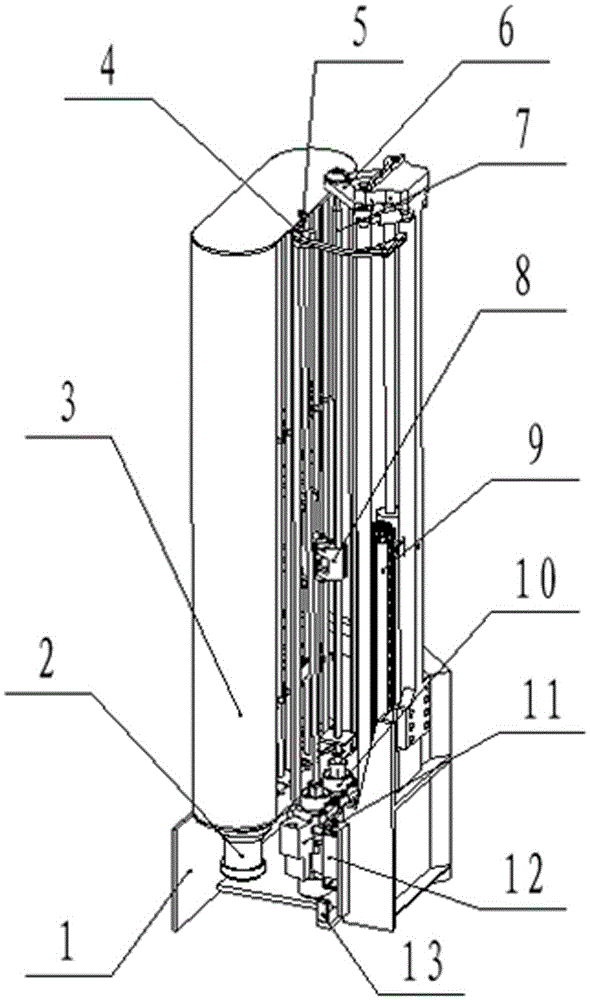

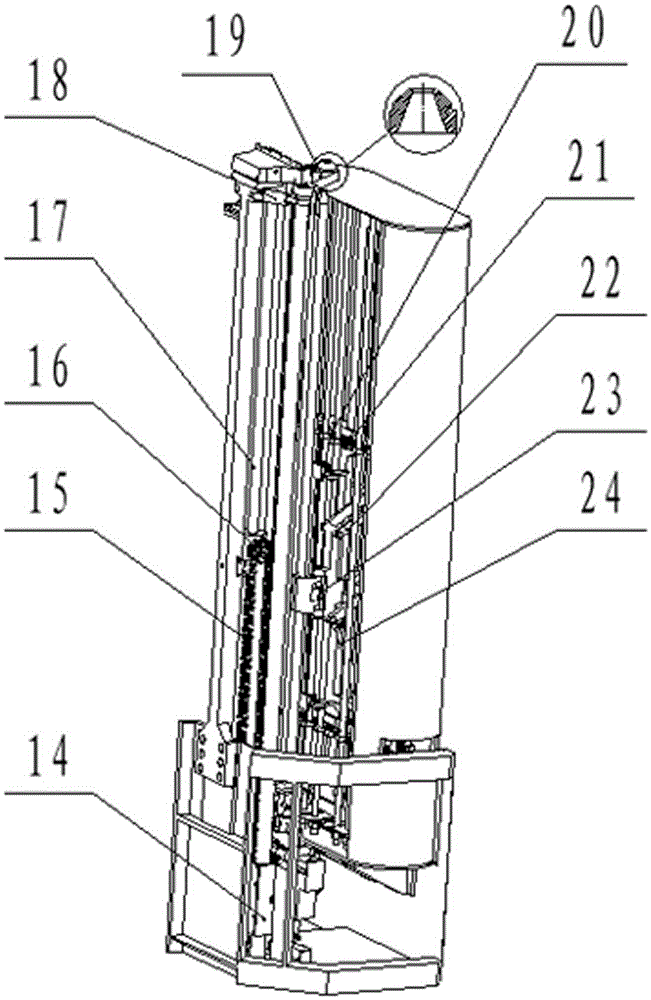

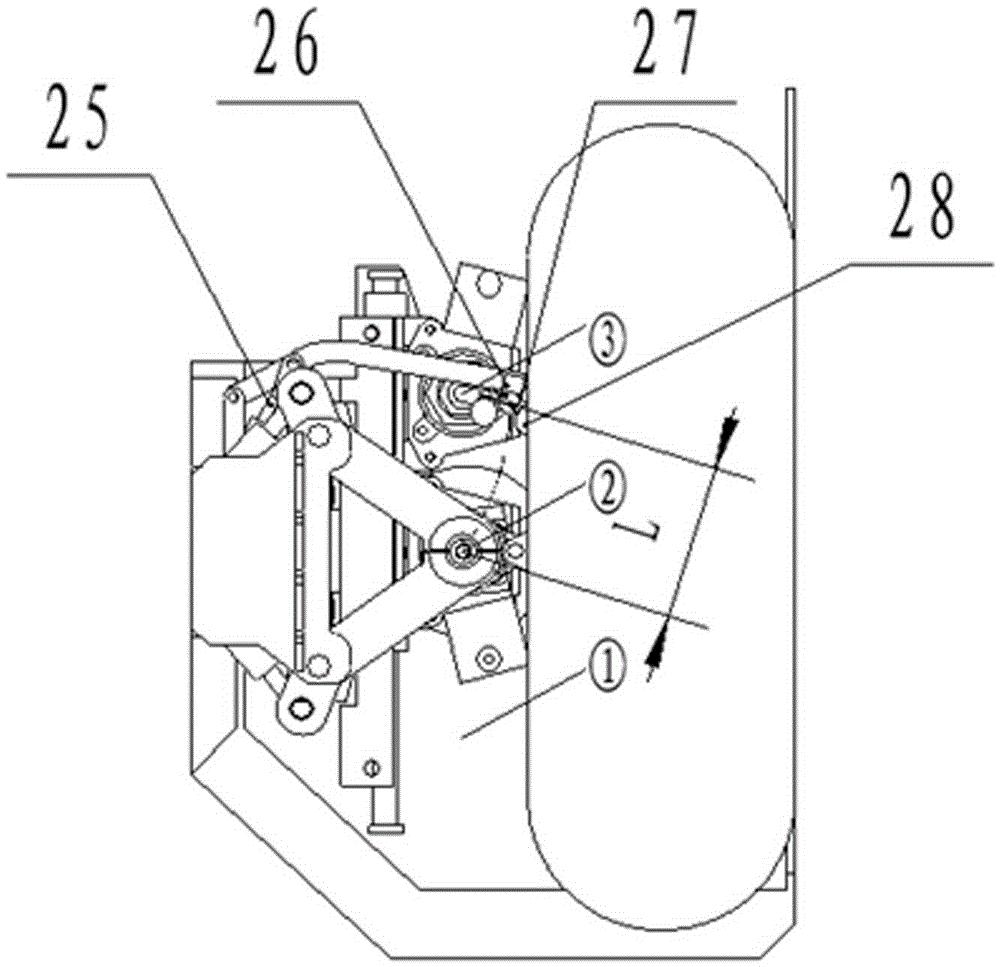

[0041] Such as figure 1 , 2 The double-drill box switchable automatic rocker drilling rig shown includes a frame 1, a large-capacity rocker bin 3 and a feed mechanism 9, and the bottom of the large-capacity rocker bin 3 is provided with a rocker bin drive motor 2. The described The large-capacity bolt storehouse 3 includes a storehouse body connected to the frame 1 . The storehouse body is provided with a transmission chain 20 on which spring clips 21 are installed. The transmission chain 20 is driven by the bolt storehouse drive motor 2 .

[0042] The large-capacity rock bolt storehouse 3 is the main device of the fully automatic rock bolt rig, which realizes the storage and delivery of rock bolts. The anchor rod 7 is manually fixed in the spring clip 21 on the anchor rod transmission chain 20, and the large-capacity anchor rod storehouse can carry a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com