Protective atmosphere vacuum sintering furnace with high temperature of 1800 DEG C

A vacuum sintering furnace, high temperature protection technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve problems such as low yield of sintered products, volatilization of silicon vapor, and easily damaged equipment, and achieve insulation and sealing problems and improve Equipment reliability and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

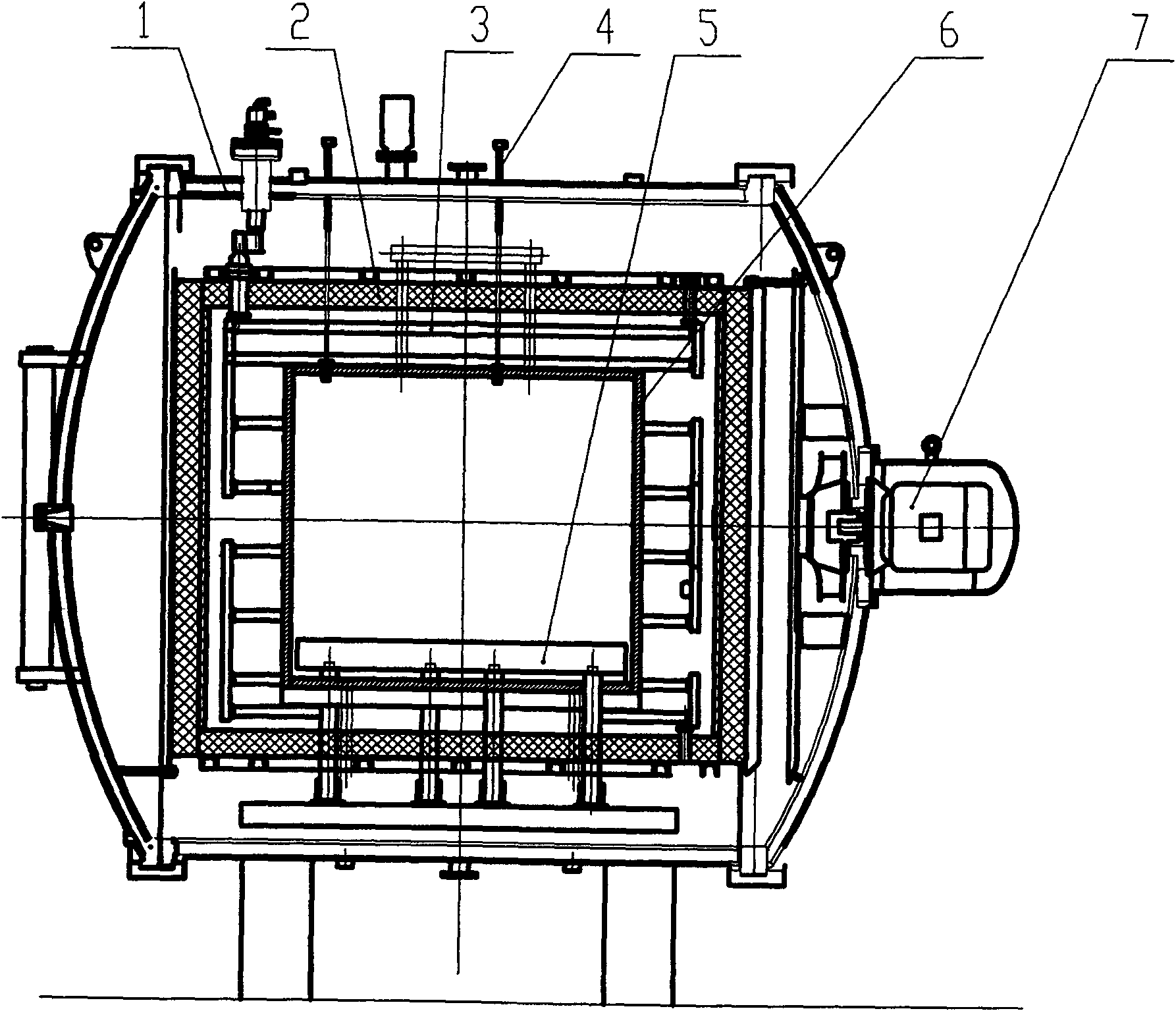

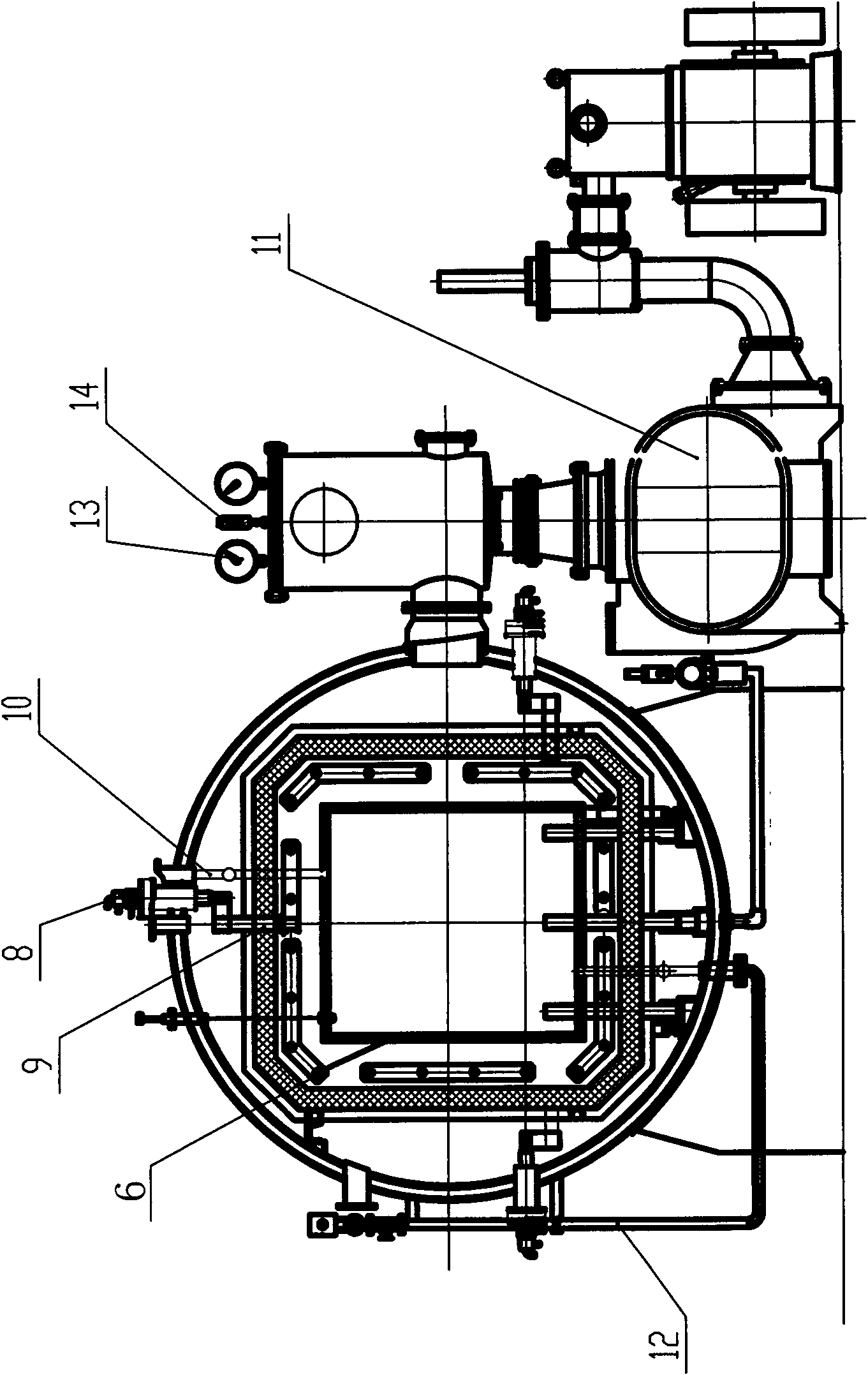

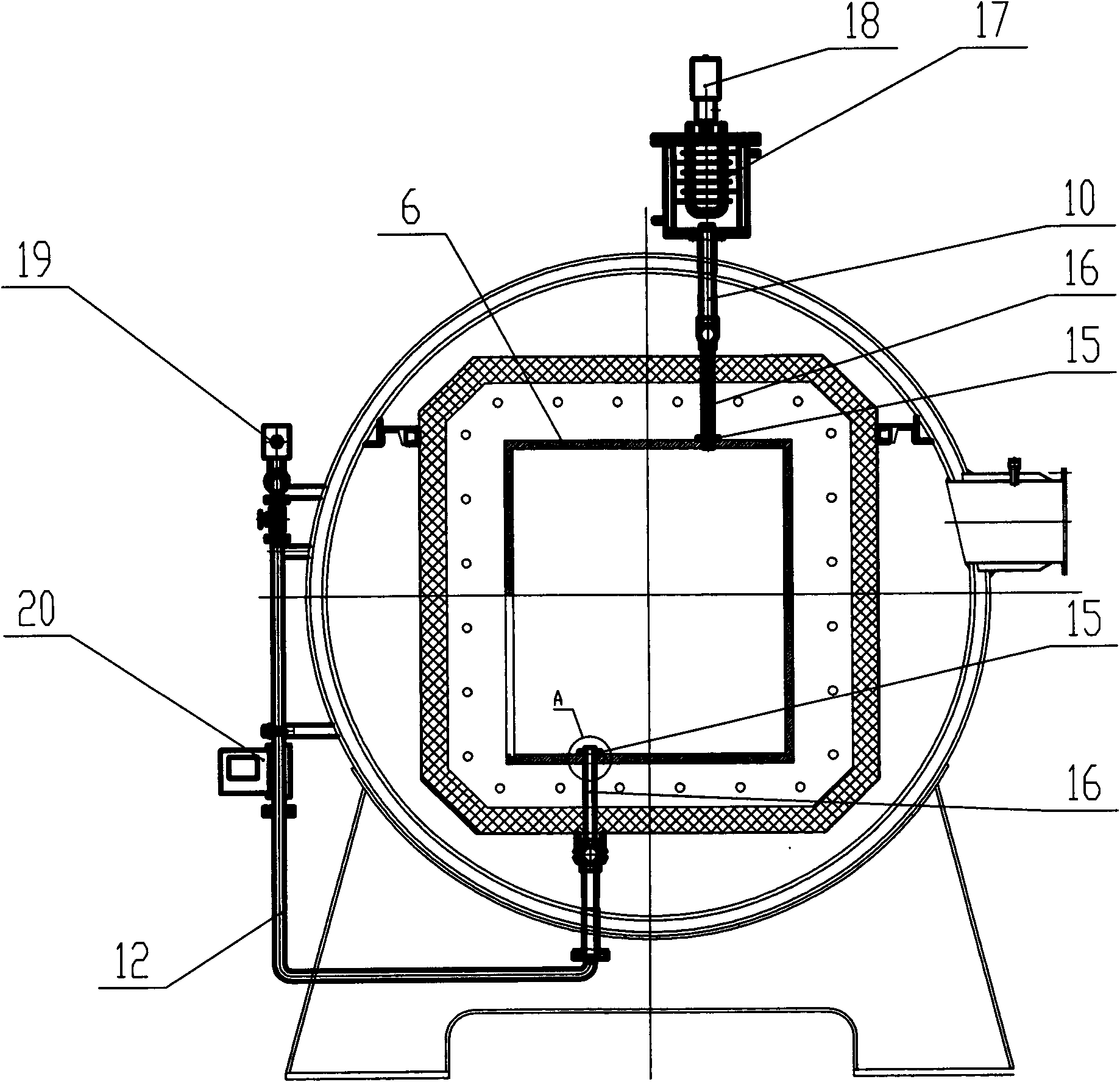

[0019] 1800 degree high temperature protective atmosphere vacuum sintering furnace of the present invention, see figure 1 , figure 2 : The furnace shell 1 is a cylinder, installed axially and horizontally, and the furnace end is opened. It is characterized in that the furnace shell 1 is equipped with a square heating chamber 2, and the graphite heater 3 is fixed on the four walls of the heating chamber 2. Inside the heater 3 Sealing box 6 is installed again, and the base plate of support rack 5 is parallelly fixed in housing 1, and its vertical column passes heating chamber 2, sealing box 6, and horizontal plate is installed in sealing box 6 at the column upper end. The air intake duct 10 and the exhaust duct 12 of the Unicom sealed box 6 pass through the heating chamber 2 and the upper and lower walls of the sealed box 6 through the graphite tube 16 to communicate with the box, see image 3 The thermocouple 4 for measuring temperature is fixed on the housing 1, and its temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com