Device for conducting electroplating process and electroplate liquid development experiment in high-pressure environment

An electroplating process and high-voltage environment technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems such as the normal pressure Hall cell test device cannot meet the high-voltage reaction conditions, the insulating material is not capable of high-voltage conditions, and the electrode is easy to expand and deteriorate. , to achieve the effect of convenient application, less liquid consumption and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

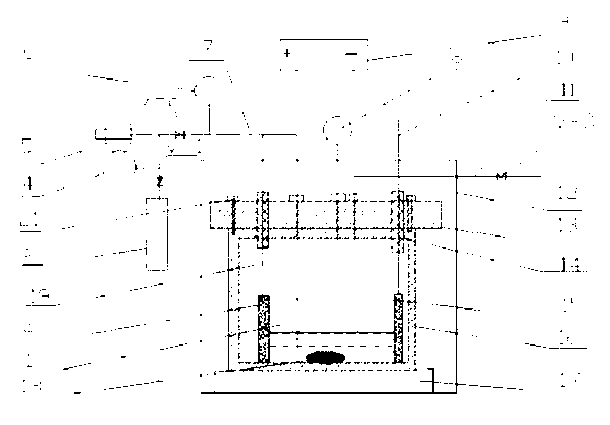

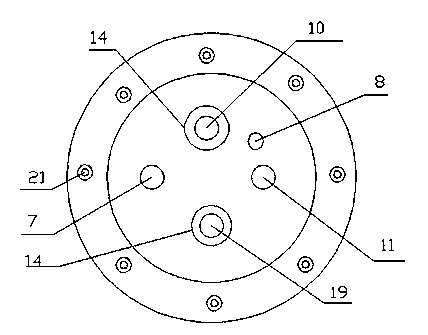

[0022] see figure 1 with figure 2 , in this embodiment, a kind of device that carries out electroplating process and electroplating solution development test under high pressure environment, comprises ladder-shaped reactor 1, anode 2, negative electrode 15 and external power supply 9, holds electroplating solution in trapezoidal reactor 1, An anode 2 and a cathode 15 are respectively placed on the non-parallel opposite sides of the trapezoidal reactor 1 to form a two-electrode system. The anode 2 is connected to the positive end of the external power supply 9 through the anode electrode wire 19, and the cathode 15 is connected to the external power supply 9 through the cathode electrode wire 10. The negative terminal of the high-voltage electrochemical reactor, CO 2 The conveying system, pressure control system, temperature control system and stirring system, the trapezoidal reactor 1 is set inside the high-pressure electrochemical reaction kettle, and the external power sup...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, especially in that:

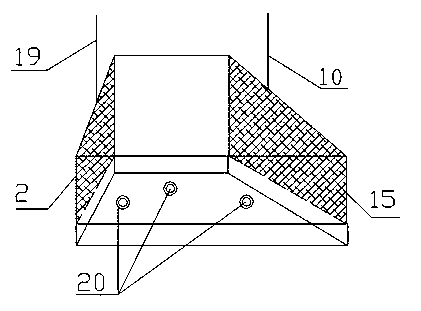

[0030] In this example, see image 3 , by using polytetrafluoroethylene fixing bolts 20, the trapezoidal reactor 1 is fixedly connected and installed with the high-pressure electrochemical reactor. The fixing bolts are made of polytetrafluoroethylene, which solves the problem that insulating materials such as plexiglass or hard polyvinyl chloride commonly used in the atmospheric pressure Hall cell test device are not suitable for high pressure conditions, especially in supercritical or subcritical CO 2 It is easy to expand and deteriorate and the electrode insulation and sealing problems in the middle, it is convenient to obtain the electroplating effect of the plating solution in a wide range of current density in a high-voltage environment in a short time, and it is suitable for high-voltage CO 2 The development of electroplating process, the formulation of electroplating solution and the de...

Embodiment 3

[0032] This embodiment is basically the same as the previous embodiment, and the special features are:

[0033] In this embodiment, at least one layer of polytetrafluoroethylene insulating layer is wrapped around the wire section of the wire section where the anode electrode wire 19 and the cathode electrode wire 10 enter the high-voltage electrochemical reactor, which can adapt to the supercritical CO 2 or subcritical CO 2 Conduct Hall cell tests in homogeneous and multiphase systems composed of conductive solutions, and use polytetrafluoroethylene insulating coatings to achieve the purpose of insulating electrode wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com