Gas cylinder with fully-wound plastic liner and molding technology thereof

A technology of winding gas cylinders and liners, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve problems such as leakage and insufficient sealing reliability, and achieve simple molding process, simple assembly, Sealed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

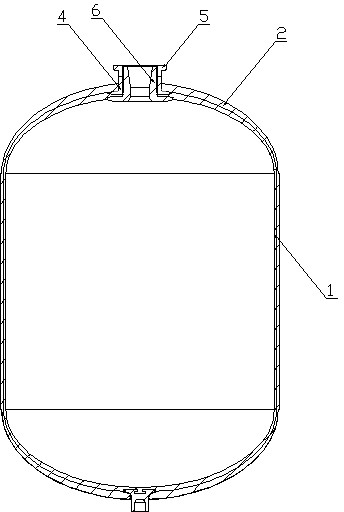

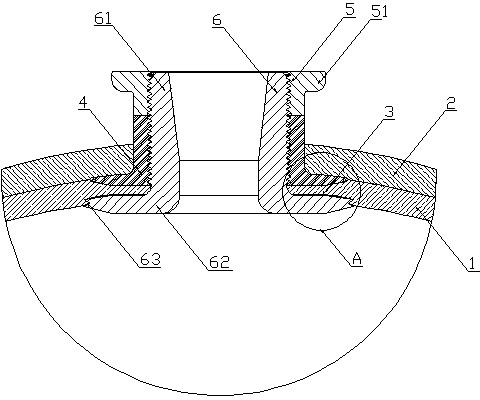

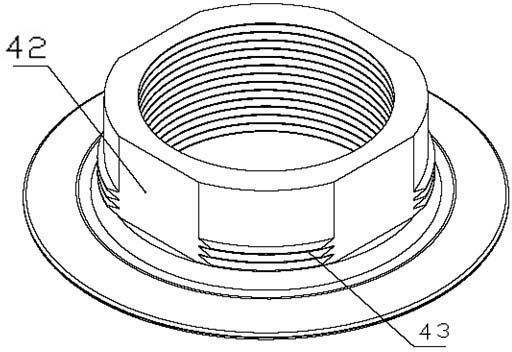

[0032] According to attached figure 1 to attach image 3, plastic liner full-wound gas cylinder, adopts the principle of metal flange sealing, through a unique molding process, with the inner liner 1 port as the sealing base surface, the reliability of the connection between the sealing material and the metal and the resulting sealing problems, The gas cylinder has good airtightness; by fastening the milled mouth 42 and the limit boss 43 on the outer wall of the flange 4, the torsion resistance and impact resistance of the gas cylinder are improved, and the technology of refillable gas cylinders is met. and security requirements. The plastic liner 1 fully wound gas cylinder includes the bottle body and the bottle mouth, the bottle body includes the plastic liner 1, and the bottle mouth includes the valve seat 6, the valve seat 6 is matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com