Method for butting concrete prefabricated member consisting of prefabricated member connector

A technology for prefabricated components and connectors, applied in building construction, infrastructure engineering, sheet pile walls, etc., can solve problems such as failure of insertion, loss of the function of blocking tapered sleeves, damage to butt joints, etc., to avoid damage, Ensuring reliability and solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

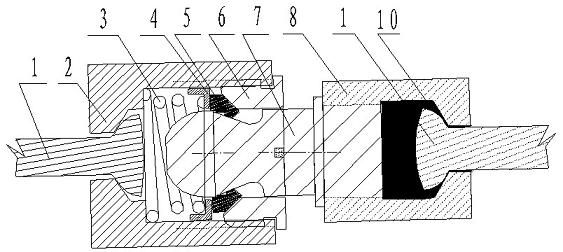

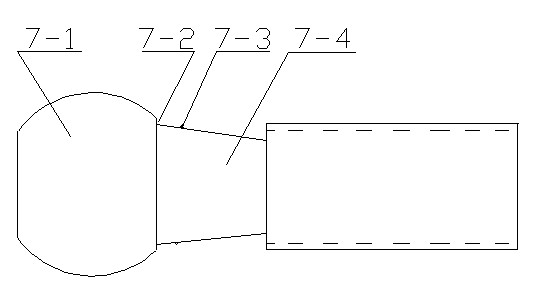

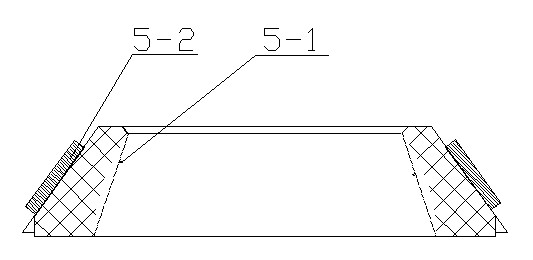

[0015] Embodiment 1: with reference to attached Figure 1-3 . A prefabricated component connector, which includes a small nut 8, an insert rod 7, a medium-hole nut 6, and a large nut 2. There is a hole at the bottom of the large nut 2, and the steel rod 1 is stuck in it, and the spring 3 is located in the big nut 2 and one end of the spring 3 is in contact with the heading head, and the other end is in contact with the split collar 5. The middle hole nut 6 is screwed into the big nut 2, wherein the middle hole nut 6 The lower end is elastically matched with the split collar 5, and the brim of the middle hole nut 6 is clamped on the end face of the large nut 2; 5, the circular area of the bottom of the plug 7-1 is greater than the circular area of the plug neck 7-4 integrated with it and forms a ring plug neck 7-4 ring card platform 7-2; the plug body of the plug 7-1 7-5 is screwed with small nut 8.

[0016] One or more rings of annular bead 7-3 are formed on the insert ...

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, a spacer 4 is provided between the spring 3 and the split collar 5, and the gasket 4 mainly supports the function of the split collar 5, which is convenient for the split collar 5 Install.

Embodiment 3

[0023] Embodiment 3: with reference to attached Figure 4 and 5. On the basis of Embodiment 1, the butt joint method of concrete prefabricated components composed of prefabricated component connectors, preparations before docking: Among the butt joint surfaces of the two concrete prefabricated components A and B to be butted, the butt joint surface ring of A concrete prefabricated components There are a plurality of large nuts 2 built into the surface, steel rods 1 are pierced in the holes at the bottom of the large nuts 2, the upsetting head of the steel rods 1 is stuck in the large nuts 2, the spring 3 is loaded into the large nuts 2 and one end of the spring 3 It is in contact with the heading head, and the other end is in contact with one side of the loaded split collar 5. The middle hole nut 6 is screwed into the large nut 2, and the lower end of the middle hole nut 6 is connected to the other side of the split collar 5. It is an elastic fit, and the brim of the middle-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com