Method for laser-induced self-propagating connection between carbon fiber reinforced aluminum-based composite and metal

A technology for strengthening aluminum matrix and composite materials, which is used in laser welding equipment, welding/cutting media/materials, metal processing equipment, etc. It can solve the problems of deteriorating base metal performance, severe interface reaction, and high heating temperature, and maintain excellent characteristics. , the effect of good connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

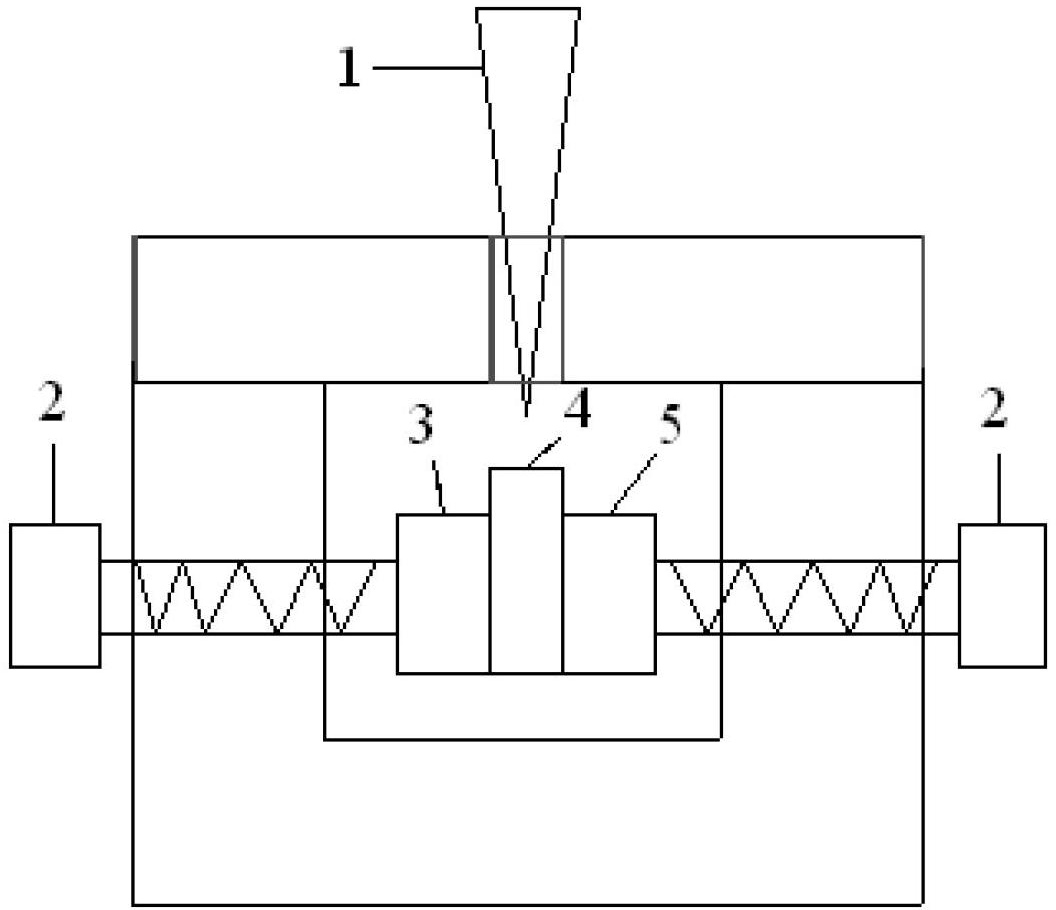

[0012] Specific embodiment 1: A method for laser-induced self-propagating connection of carbon fiber reinforced aluminum matrix composites and metals in this embodiment is carried out according to the following steps: 1. 35-39 parts by weight of titanium powder, 58- Mix 62 parts of aluminum powder and 2~4 parts of nano-carbon powder evenly, put them in the ball mill tank, put the balls in the ratio of ball to material mass ratio of 5:1, and under the condition of argon protection, use 300~ Ball milling at a speed of 500r / min for 2-3 hours to obtain mixed powder; 2. Press the mixed powder obtained in step 1 into an intermediate laminate compact with a relative density of 60%-80% and a thickness of 1-3mm, and seal it for storage; 3. The intermediate laminate obtained in step 2 is placed between the carbon fiber reinforced aluminum matrix composite material and the metal to assemble a "sandwich" assembly, and then the assembly is clamped and placed in the laser equipment. Under th...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the particle size of the nano-carbon powder in Step 1 is 12500 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that: the titanium powder in step 1 is 325-1000 mesh, and the aluminum powder is 325-1000 mesh. Others are the same as the specific embodiment 1 to 2.

[0016] Verify effect of the present invention by following test:

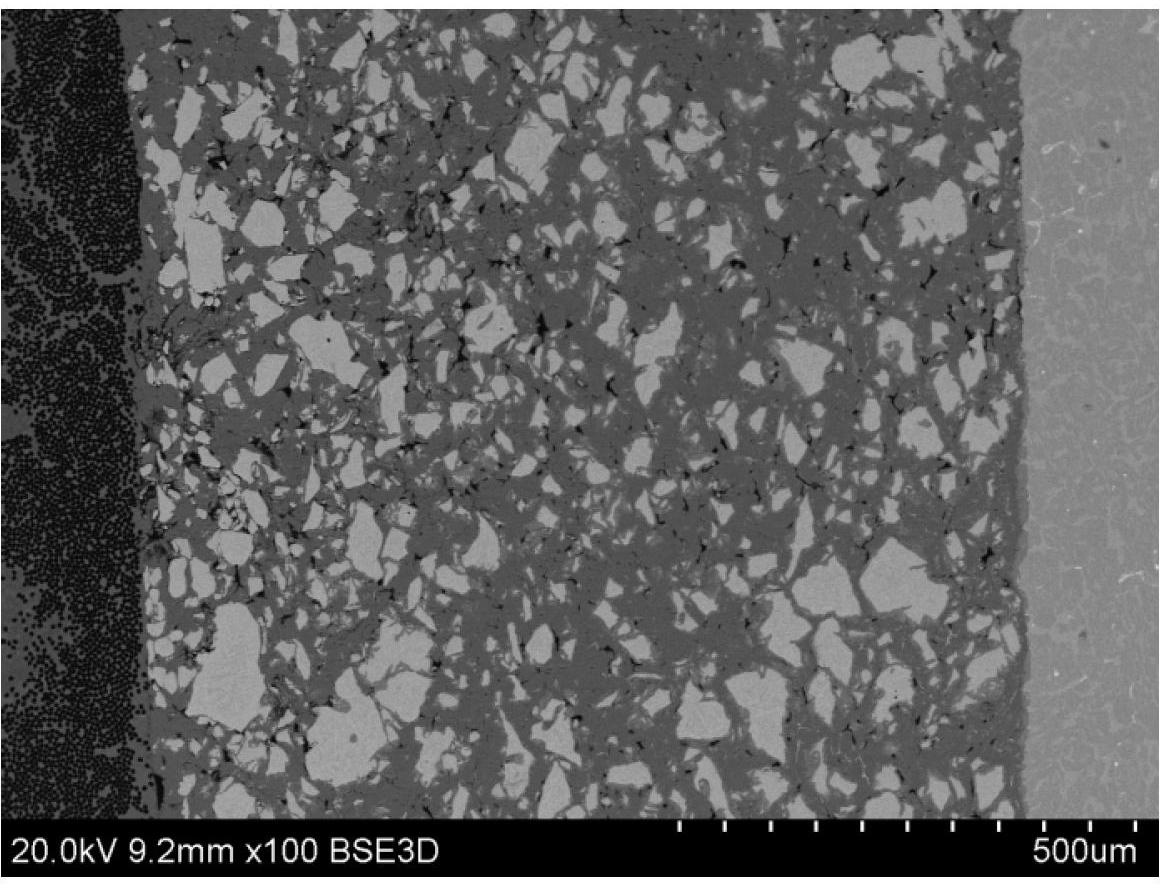

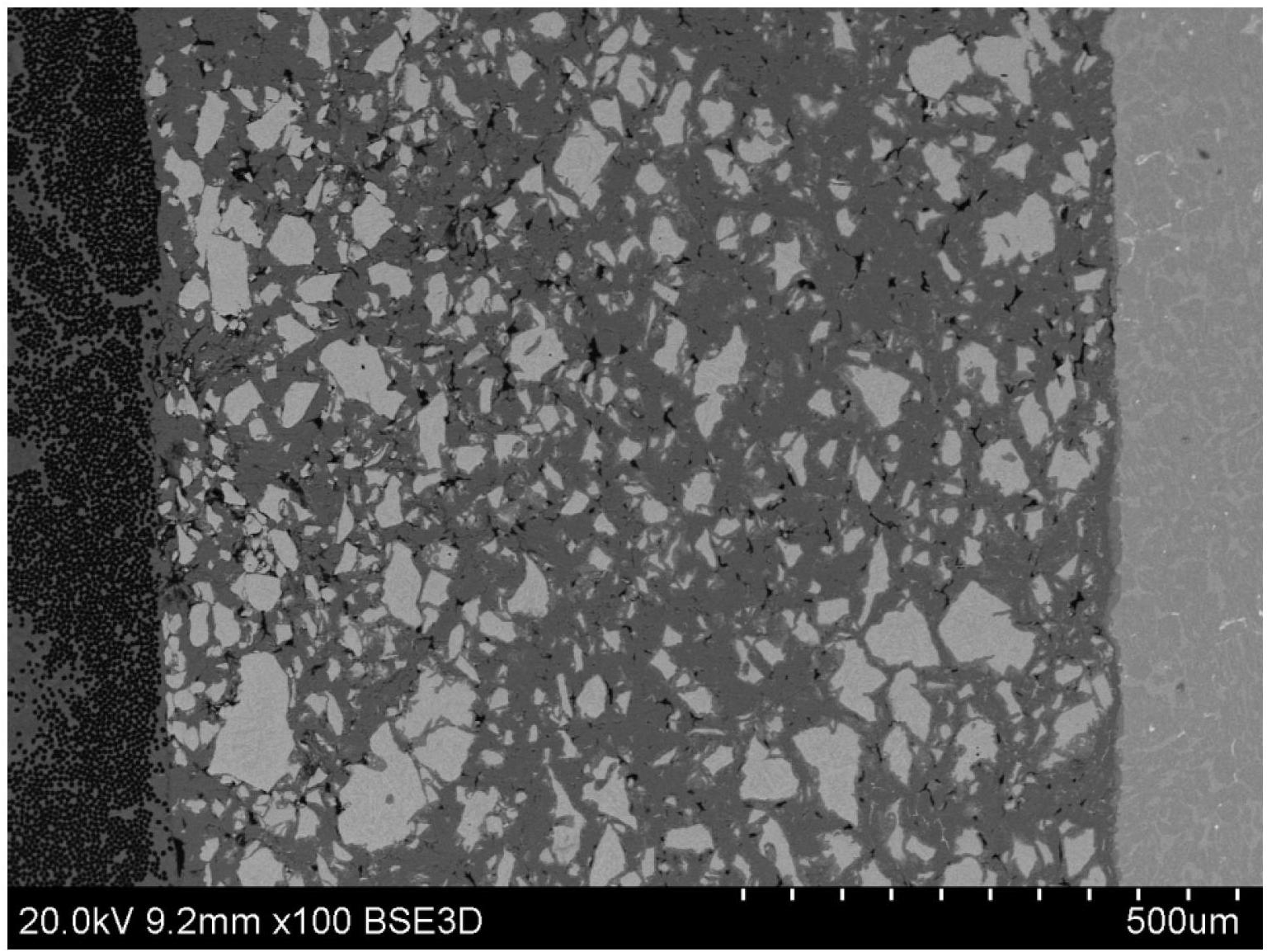

[0017] A method for laser-induced self-propagating connection of carbon fiber reinforced aluminum matrix composites and metals in this test is carried out in accordance with the following steps: 1. Weigh 3.7g of titanium powder, 6.0g of aluminum powder and 0.3g of nano-carbon powder and mix Evenly, put it in a ball mill jar, put balls in the ratio of ball to material mass ratio of 5:1, and ball mill at a speed of 300r / min for 2.5h under the protection of argon to obtain a mixed powder; 2. 1. The obtained mixed powder is pressed into an intermediate laminate compact with a relative density of 70% and a thickness of 1 mm, which is sealed and stored; 3. The intermediate laminate compact obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com