Laser-ignition unit

A laser ignition and laser technology, applied in the direction of engine ignition, spark ignition controller, engine components, etc., can solve the problems of high laser power, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

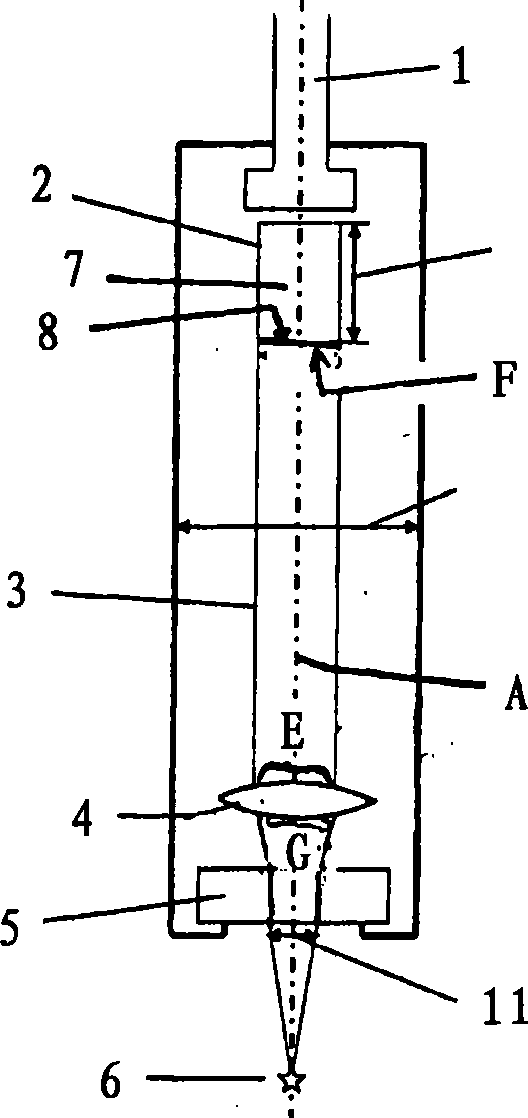

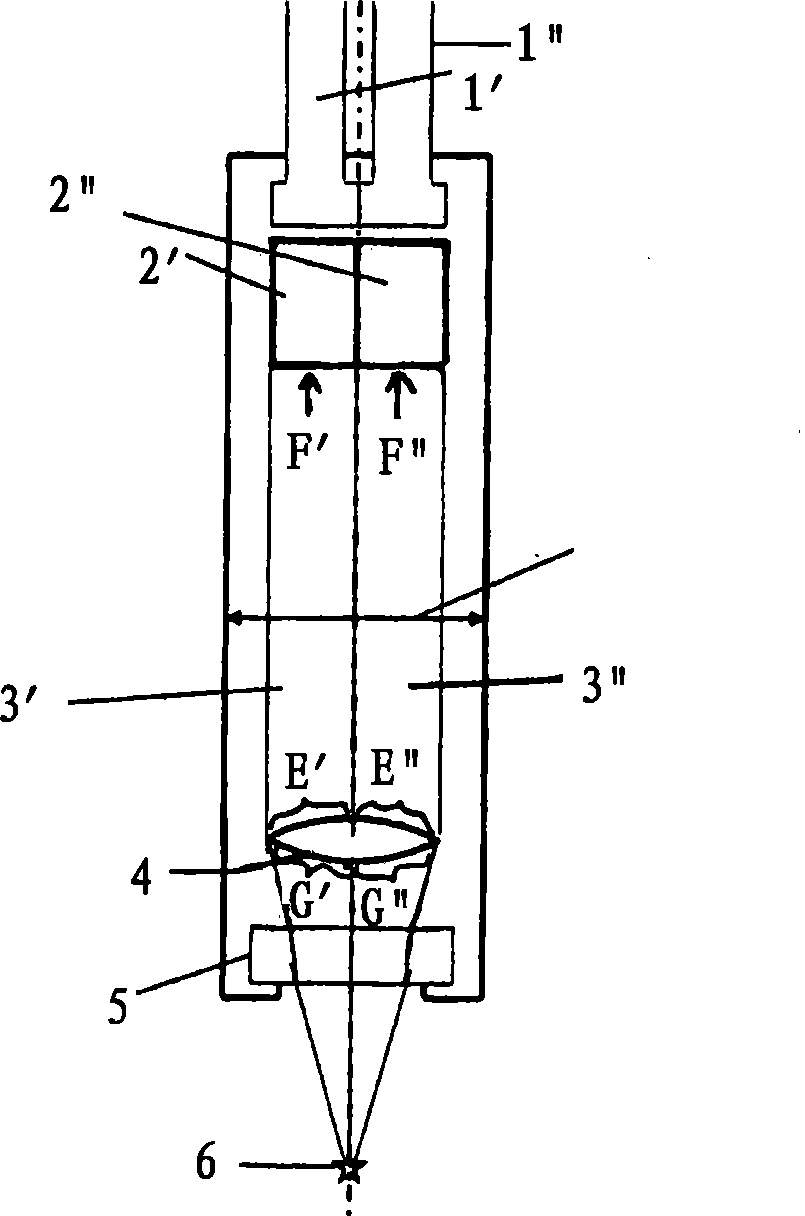

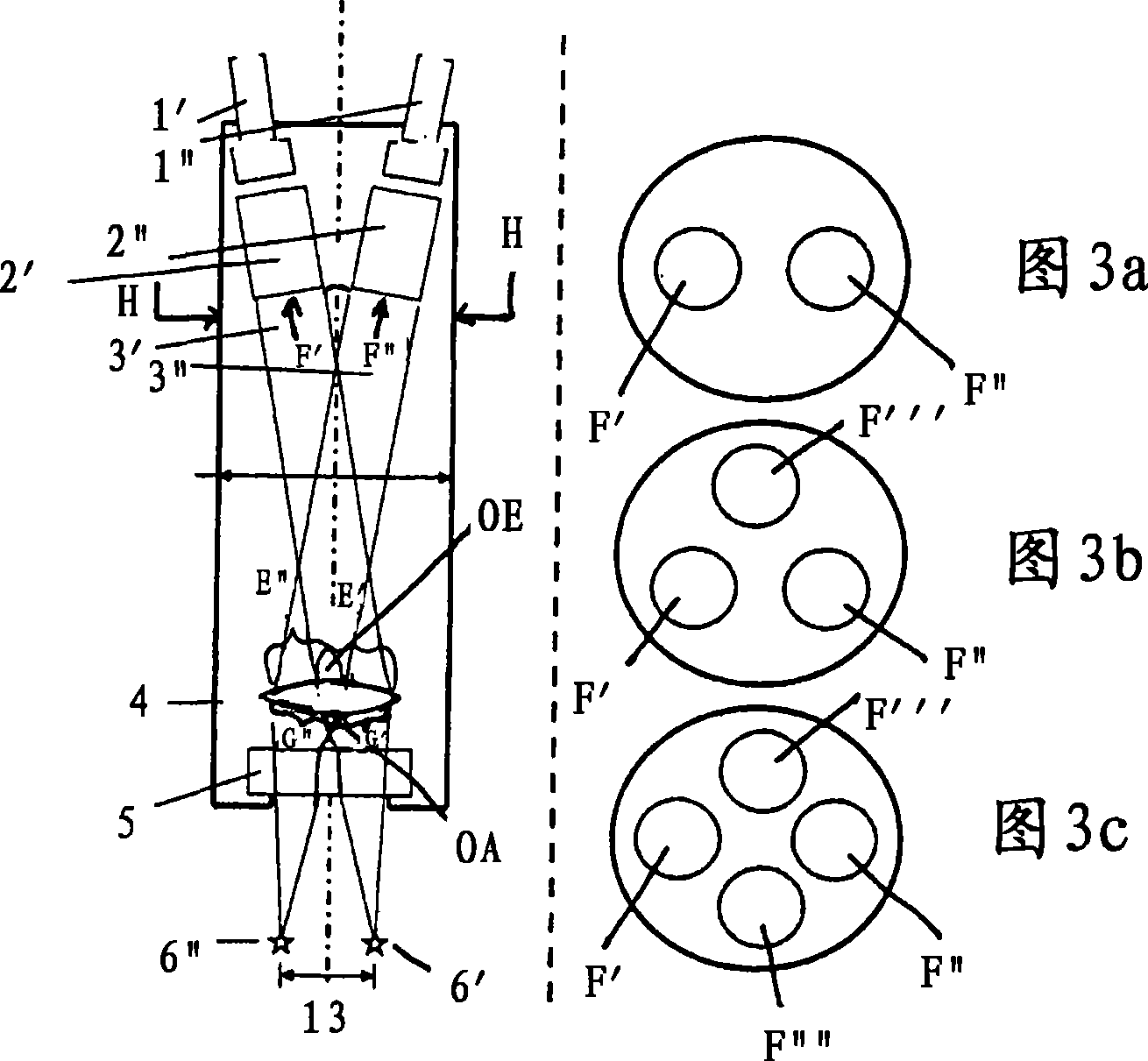

[0033] figure 1 A schematic diagram of a laser ignition device 10 according to the prior art is shown. The laser ignition device 10 is designed as a laser spark plug and comprises an ignition laser cell 2 which has a resonator 7 and an output mirror 8, so that the laser light is guided schematically via the beam path of the laser light 3 onto the input optics 8, The input optics focus the laser light 3 onto a focal point 6 where a plasma spark is generated. The laser exit surface is denoted by F and describes the surface from which the laser light of the laser generating device 2 exits before the ignitable laser light is guided onto the input optics 4 . The laser ignition device 10 is delimited by a combustion chamber window 5 through which the laser light 3 is fed into the combustion chamber 11 of the internal combustion engine 11 . The ignition laser cell 2 is supplied with pumping light by an optical waveguide 1 which is connected to a pumping light source not shown. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com