stove

A technology for stoves and burners, which can be used in home appliances, household stoves/stoves, gaseous heating fuels, etc., and can solve problems such as frightening users, loud ignition sounds, and big flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

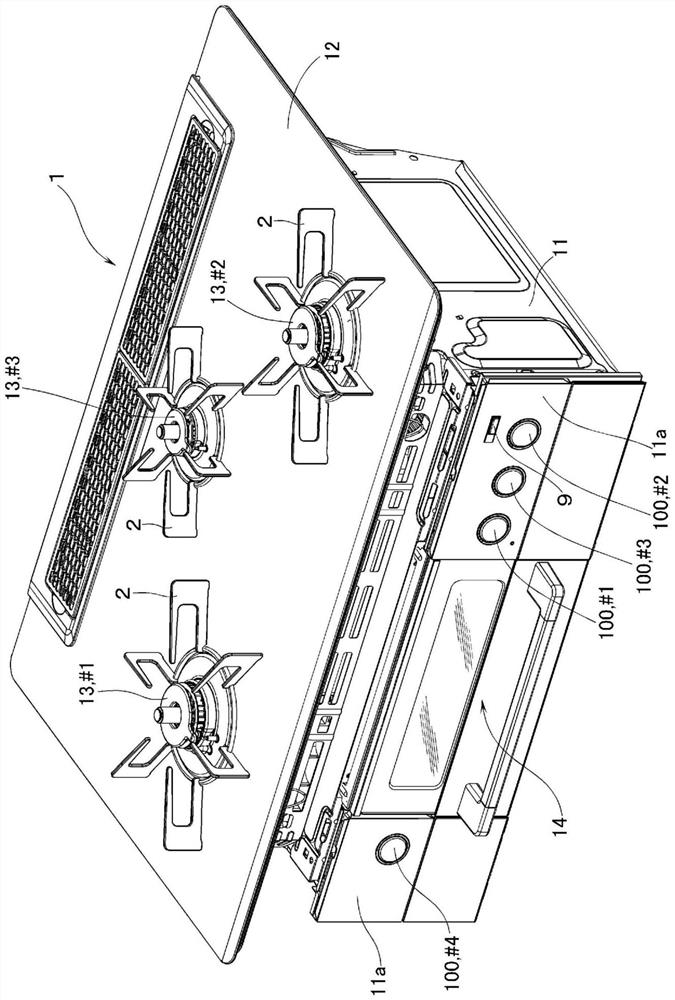

[0016] figure 1 The illustrated cooker 1 is a built-in cooker assembled in an integrated kitchen not shown. The cooker 1 includes: a cooker main body 11 provided so as to be fitted into an opening provided on the top surface of the cooktop of the integrated kitchen; and a top plate placed on the top surface of the cooktop so as to cover the upper surface of the cooktop body 11 12; The #1 burner on the left front side, the #2 burner on the right front side, and the #3 burner in the center of the rear side exposed on the top plate 12, a total of 3 burners 13; and a grill assembled in the stove body 11 (grill) 14. The burner 13 heats a to-be-cooked object (not shown) in a pot or the like placed on the stove 2 placed on the top plate 12 so as to surround the burner 13 .

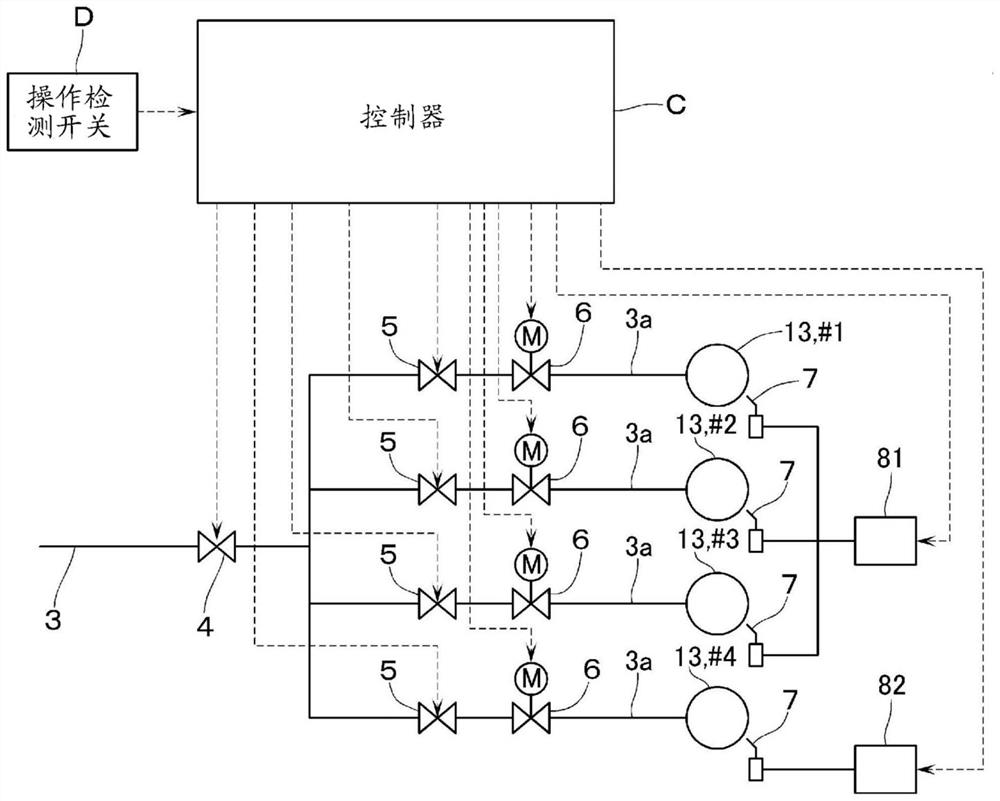

[0017] like figure 2 As shown, the gas supply path 3 for the stove 1 is directed to figure 1 Gas is supplied to the three burners 13 of the #1 burner to #3 burner shown, and the #4 burner 13 provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com