Pressure guiding tube blockage diagnosing device and blockage diagnosing method

A diagnostic device and pressure guiding tube technology, which is applied in the direction of measuring device, measuring fluid pressure, fluid tightness test, etc., can solve problems such as pressure guiding tube blockage, process variable cannot be measured correctly, and complete equipment influence. stagnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

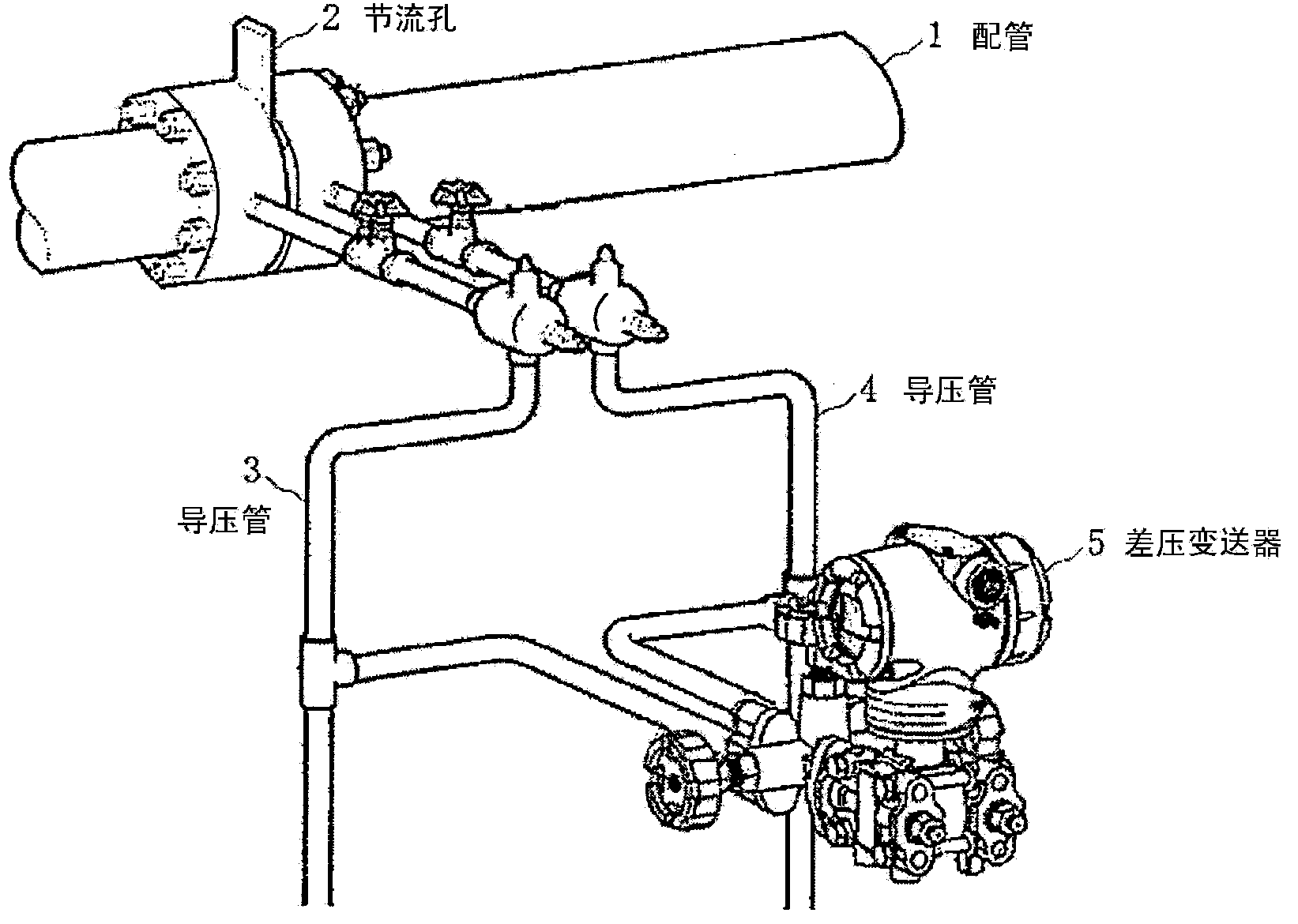

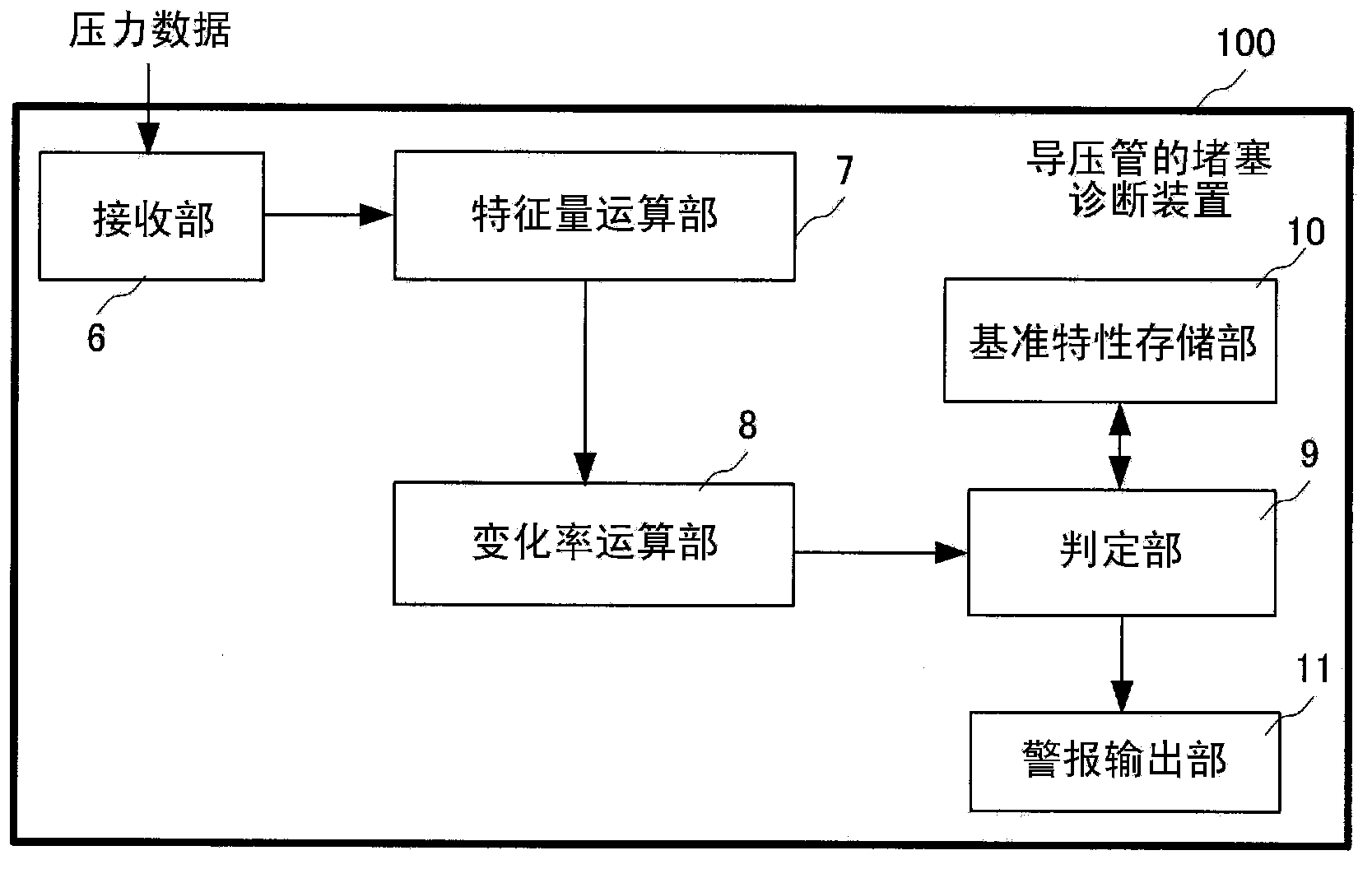

[0051] figure 2 It is a block diagram of a main part of the first embodiment (Embodiment 1) of the pressure guiding tube clogging diagnosis device of the present invention. The clogging diagnosis device 100 for a pressure guide tube includes a receiving unit 6 , a characteristic amount calculating unit 7 , a change rate calculating unit 8 , a determining unit 9 , a reference characteristic storage unit 10 , and an alarm output unit 11 .

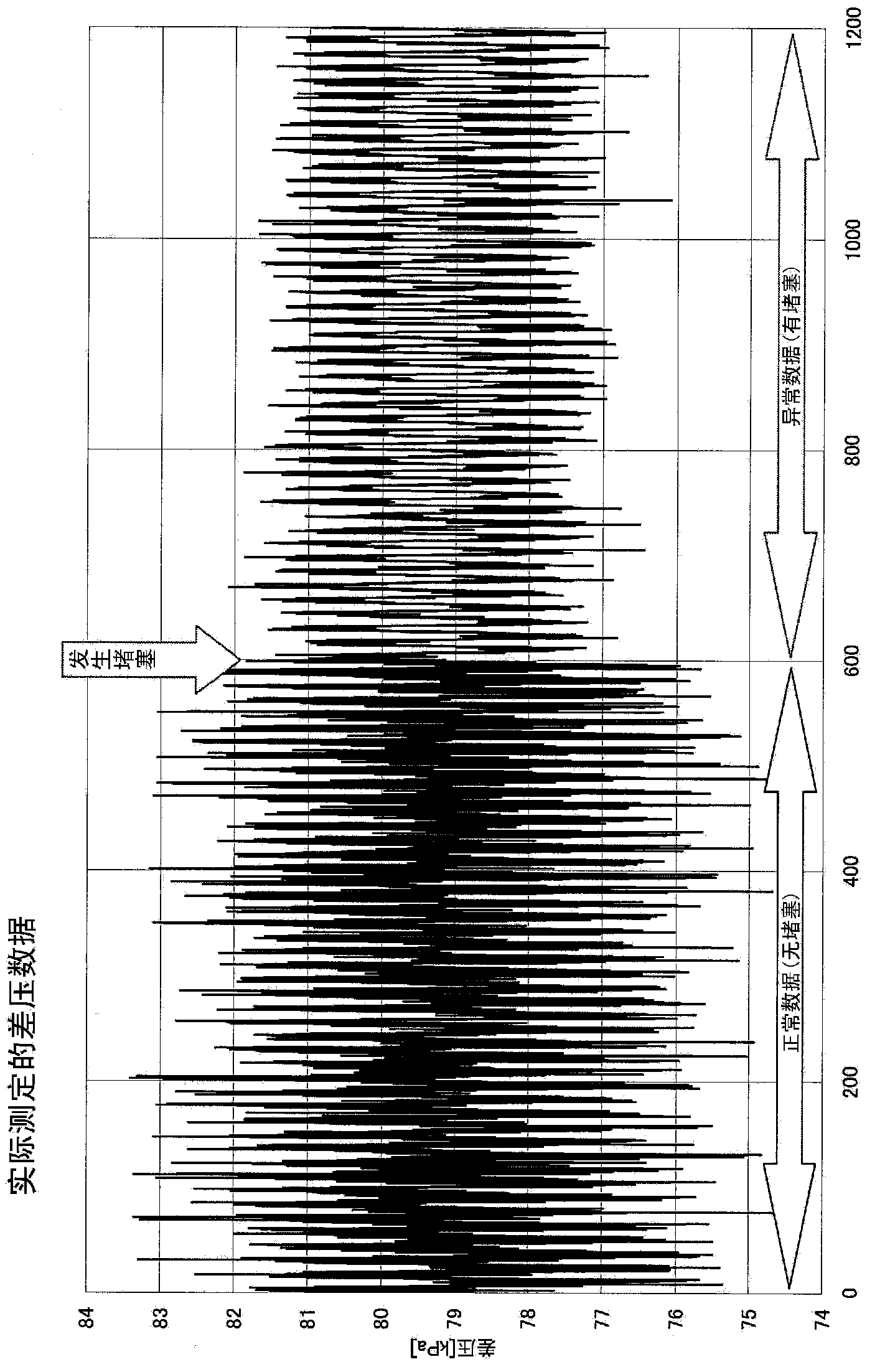

[0052] The receiving unit 6 receives differential pressure data from the differential pressure transmitter 5 . The differential pressure data from the differential pressure transmitter 5 corresponds to the pressure data from the pressure detection unit in the present invention. The feature quantity calculating unit 7 divides the time series of differential pressure data received by the receiving unit 6 into a plurality of sections, and obtains a feature quantity indicating the state of pressure fluctuation for each section. In this embodim...

Embodiment approach 2

[0084] In the first embodiment, the rate of change is obtained by the triangular moving average processing as the smoothing processing of the rate of change calculation unit 8 , and in the second embodiment, the rate of change is obtained by the least square method as the smoothing process. In addition, in this Embodiment 2, only the internal processing of the rate-of-change calculation part 8 differs, and its structure is the same as figure 2 The ones shown are the same. For this reason, for embodiment 2 also use figure 2 The structure shown will be described.

[0085] In Embodiment 2, the rate-of-change calculation unit 8 applies the least-squares method to the feature quantities of a fixed time interval up to the interval for each of the intervals to the feature quantities acquired from the feature quantity calculation unit 7 as smoothing. Processing, the slope of the obtained straight line is used as the rate of change of the interval.

[0086] An example of applying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com