Internal combustion engine

a combustion engine and combustion chamber technology, applied in the direction of machines/engines, lasers, mechanical equipment, etc., can solve the problems of less suitable for rapid pulse sequences, complex circuitry is required for control, and the device cannot be housed entirely in a component, and achieve the effect of high amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

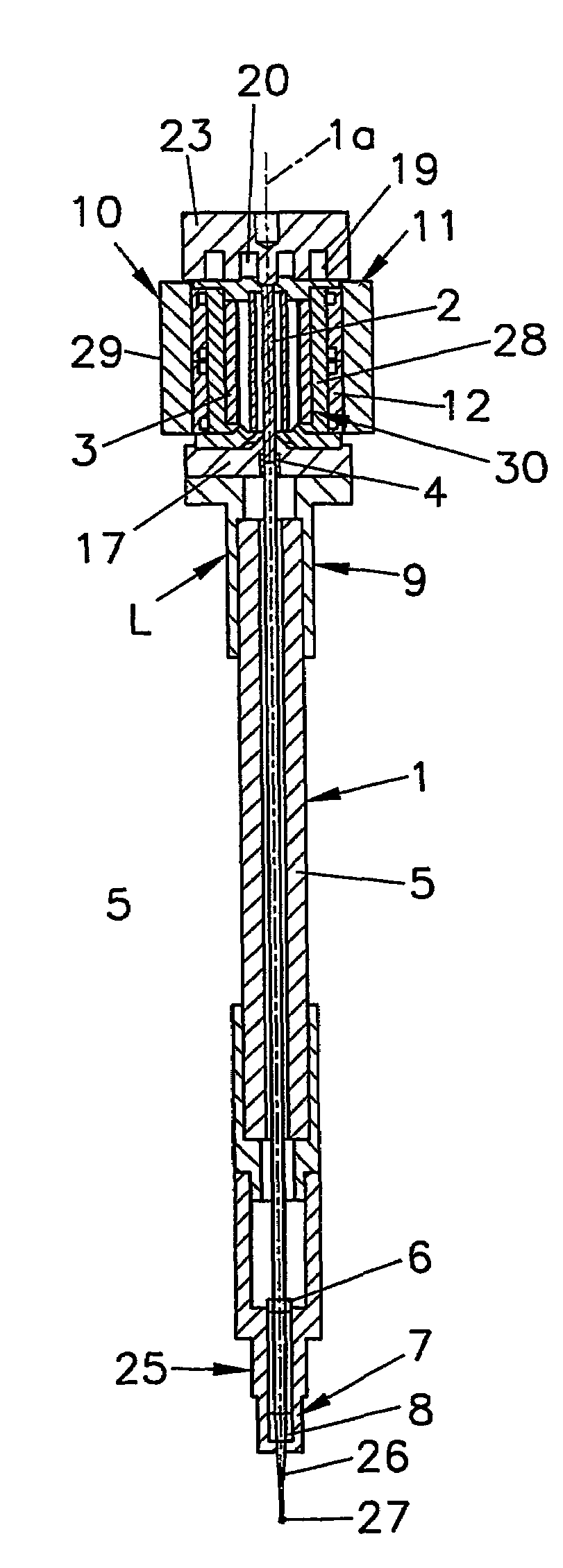

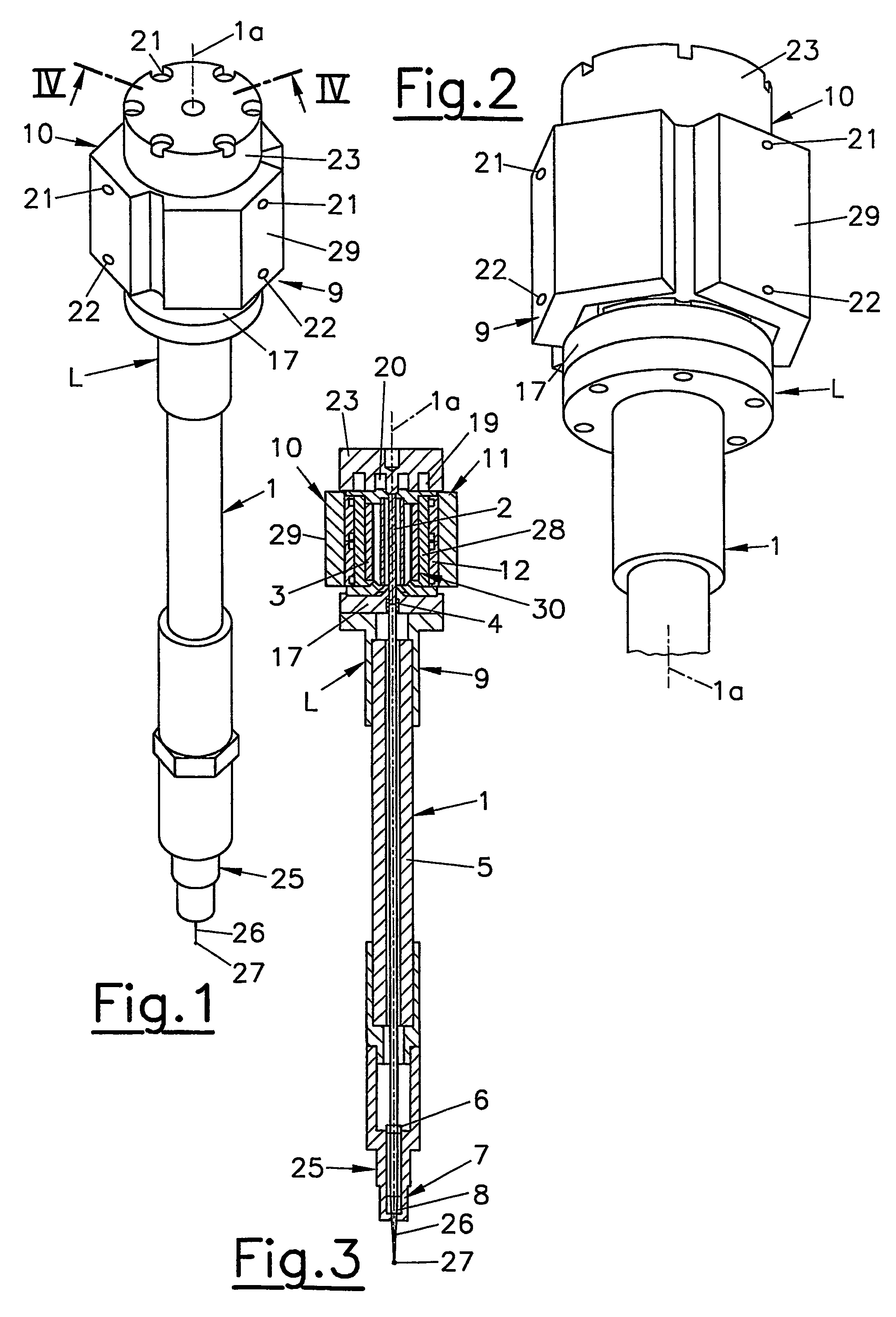

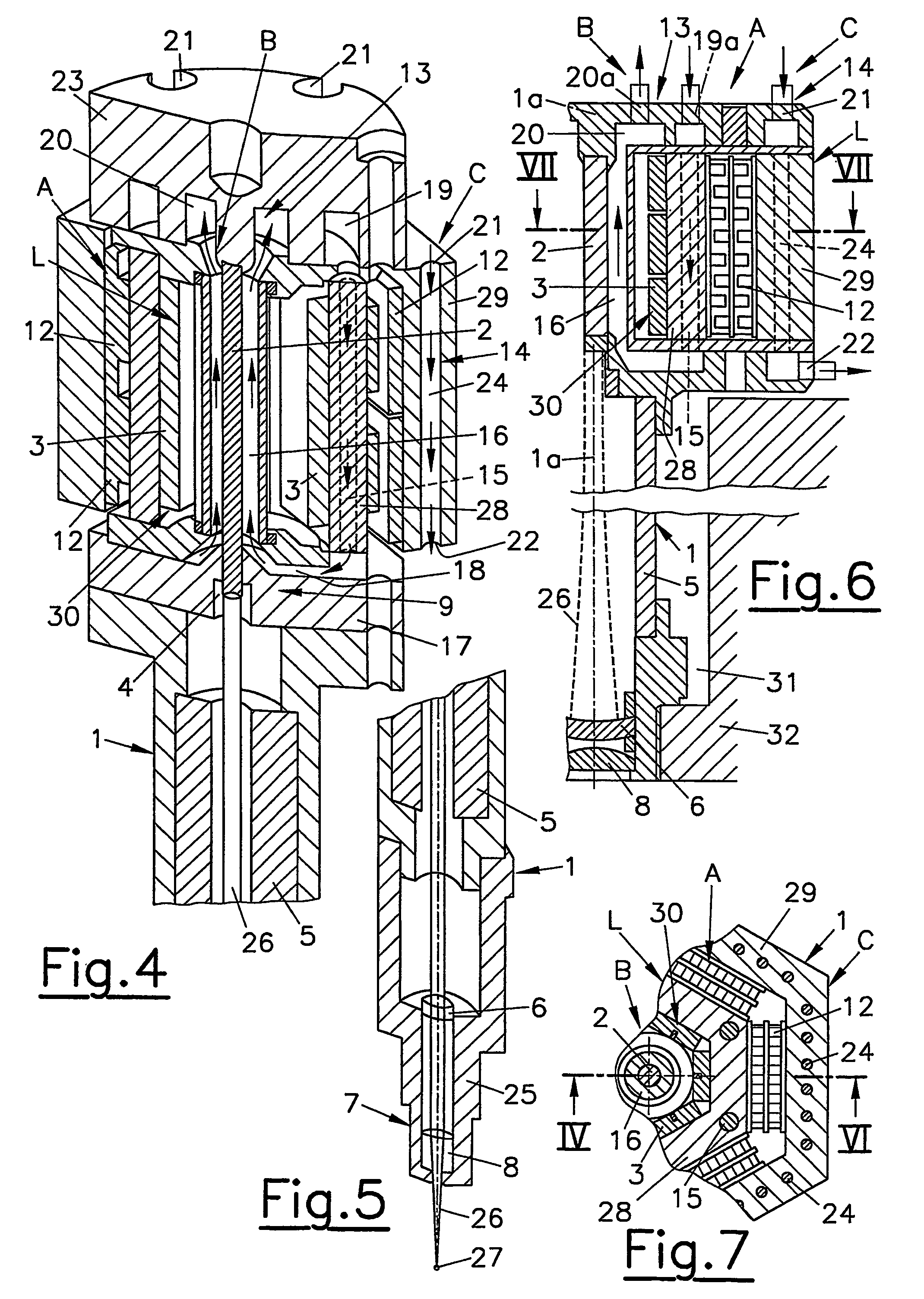

[0043]High efficiency can be achieved when the pumped light source 30 is formed by pump diodes 3.

[0044]Meta-stable energy levels are excited in the laser crystal 2 via irradiation of the pump diodes 3 (808 nm) and the energy is thus stored. As a result of a low spontaneous emission, the laser crystal 2 begins to emit light at laser wavelength (1064 nm).

[0045]For amplification and coherence of the light, the laser crystal 2 is embedded in an optical resonator 9 whose quality is increased in a pulsed manner with the passive Q-switch 4 upon reaching the desired power density. A short, strong laser pulse 26 is thus obtained at the output mirror 6.

[0046]Individual pump diodes 3 are connected in series and are arranged in an annular fashion on the side about the laser crystal 2.

[0047]Due to strongly limited life at higher operating temperatures, the pump diodes 3 need to be operated at a relatively low temperature of approx. 30° C. Moreover, the wavelength of the pump diodes 3 changes wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com