Rationed fertilizing device with fertilizer mixing function

A quantitative fertilization and functional technology, applied in fertilization devices, fertilizer dispensers, applications, etc., can solve the problems of inconvenient use, difficulty in quantitative fertilization, and inability to mix two kinds of fertilizers, and achieve the effect of preventing splashing everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

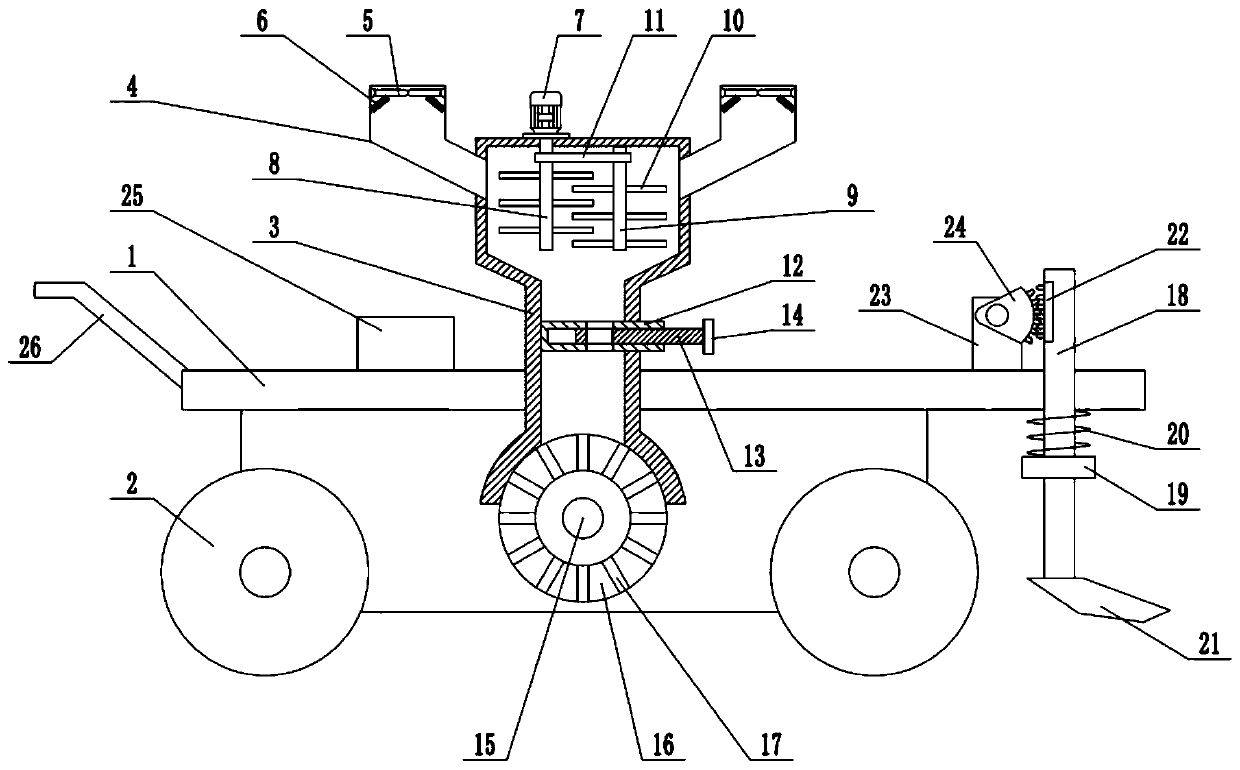

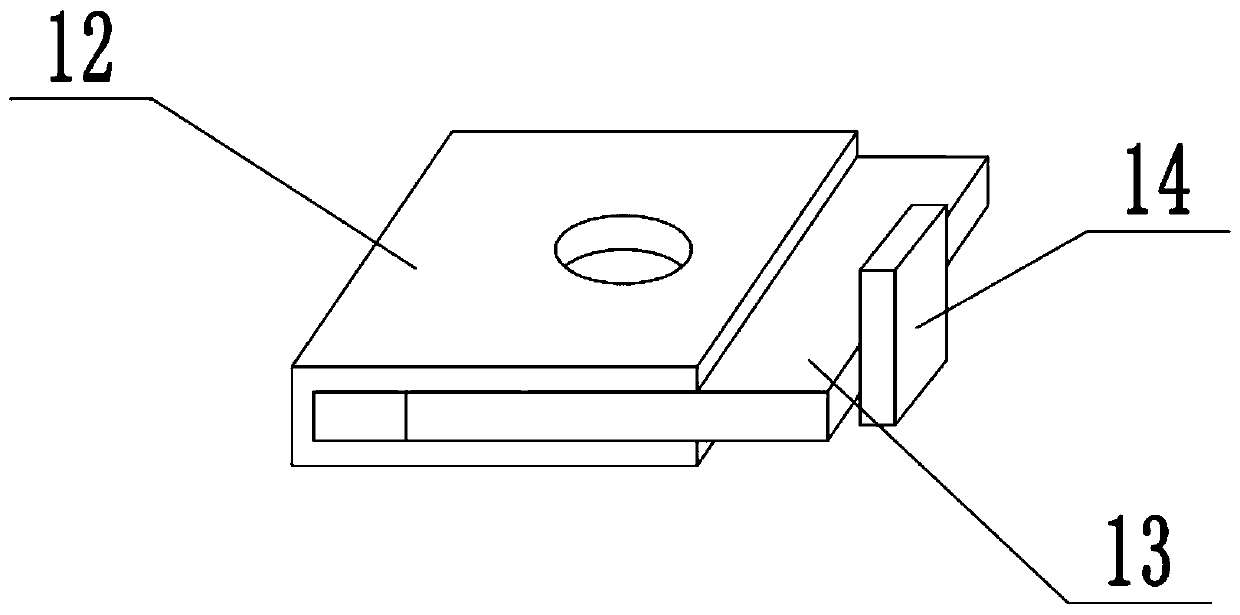

[0020] see Figure 1-3 , in an embodiment of the present invention, a quantitative fertilization device with a fertilizer mixing function includes a frame 1, a roller 2 and a mixing bin 3, the bottom of the frame 1 is equipped with a roller 2, and the left end of the frame 1 is equipped with a push rod 26. It is convenient to push the device to move the position. The mixing chamber 3 is installed on the frame 1, and the left and right ends of the top of the mixing chamber 3 are respectively installed with the feeding port 4. The top of the feeding port 4 is open, and the top of the feeding port 4 is installed with a movable plate. 5. There are two movable plates 5, which are symmetrically arranged left and right. The lower surface of the movable plate 5 is fixedly connected with a spring 6, and the lower end of the spring 6 is fixedly connected with the inner wall of the feeding port 4. The spring 6 is used to keep the movable plate 5 in a horizontal state. Two feeding ports 4...

Embodiment 2

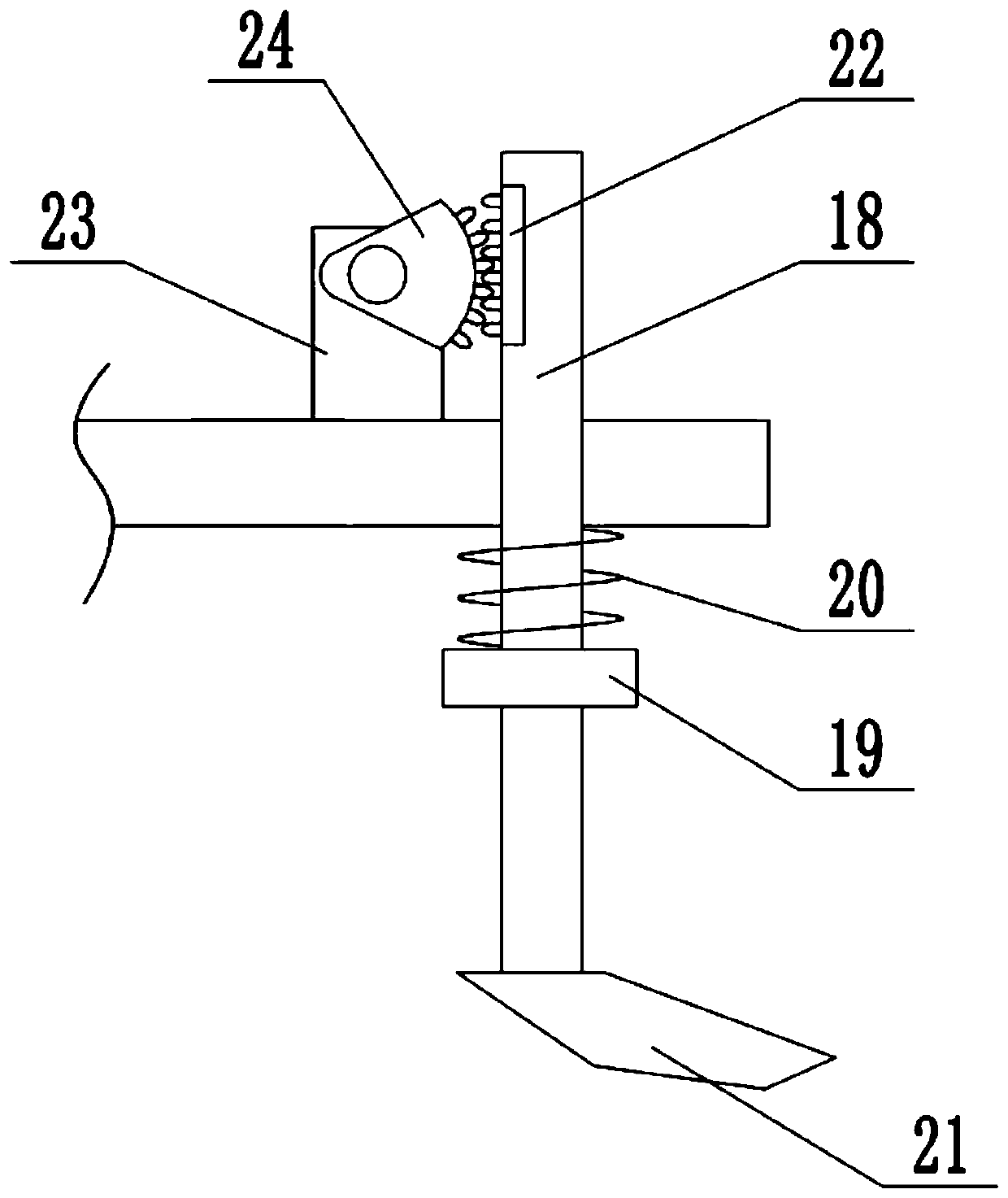

[0022] On the basis of Embodiment 1, a movable rod 18 is installed on the upper surface of the frame 1, the movable rod 18 runs through the frame 1, the movable rod 18 is slidably connected with the frame 1, the movable rod 18 can slide up and down, and the middle part of the movable rod 18 Boss 19 is processed, extension spring 20 is set on movable rod 18, the upper end of extension spring 20 is fixedly connected with the lower surface of frame 1, the lower end of extension spring 20 is fixedly connected with boss 19, and the lower end of movable rod 18 is installed Coulter 21 is arranged, and rack 22 is installed on the side wall of movable bar 18, and the left side of movable bar 18 is provided with driving motor 23, and driving motor 23 is fixedly connected with frame 1, and the axle extension end of driving motor 23 is fixedly connected with half The gear 24, the half gear 24 meshes with the rack 22, and the driving motor 23 drives the half gear 24 to rotate when it is run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com