Buffering and flow assisting powder cabin

A technology of powder flow and flow aid, which is applied in the directions of container, packaging, transportation and packaging, can solve the problems of ineffective flow aid air cushion, slow powder material, affecting work efficiency, etc., and achieves simple structure, low cost, and avoids clogging of the warehouse. body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

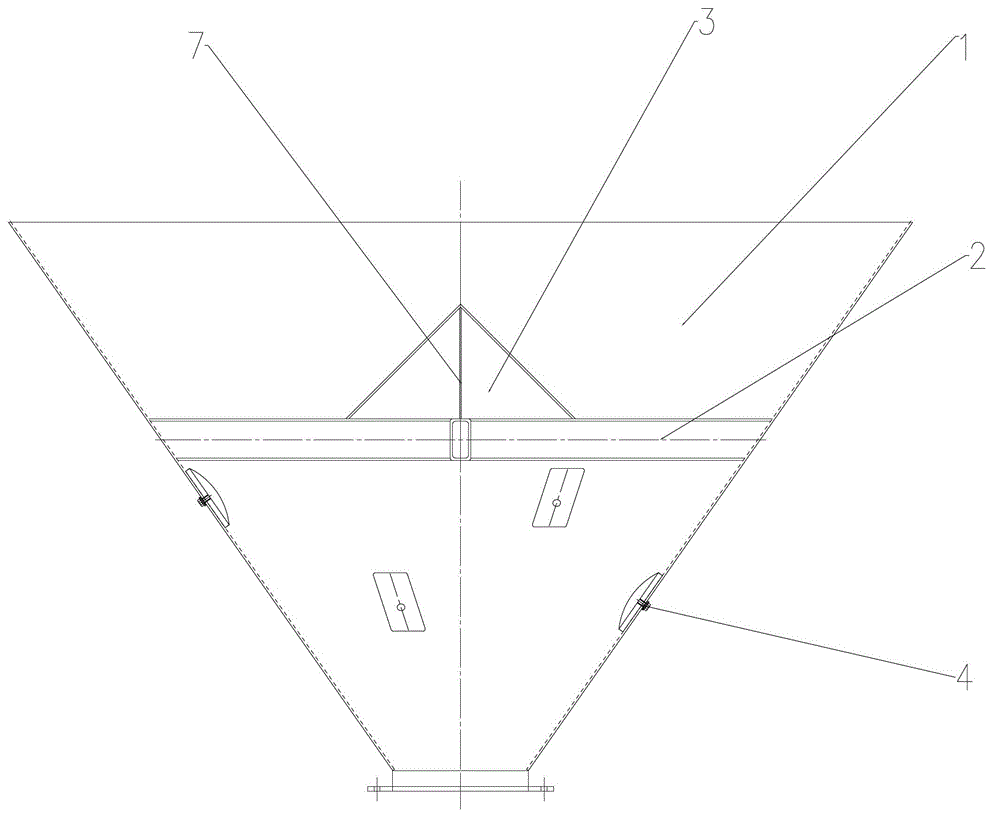

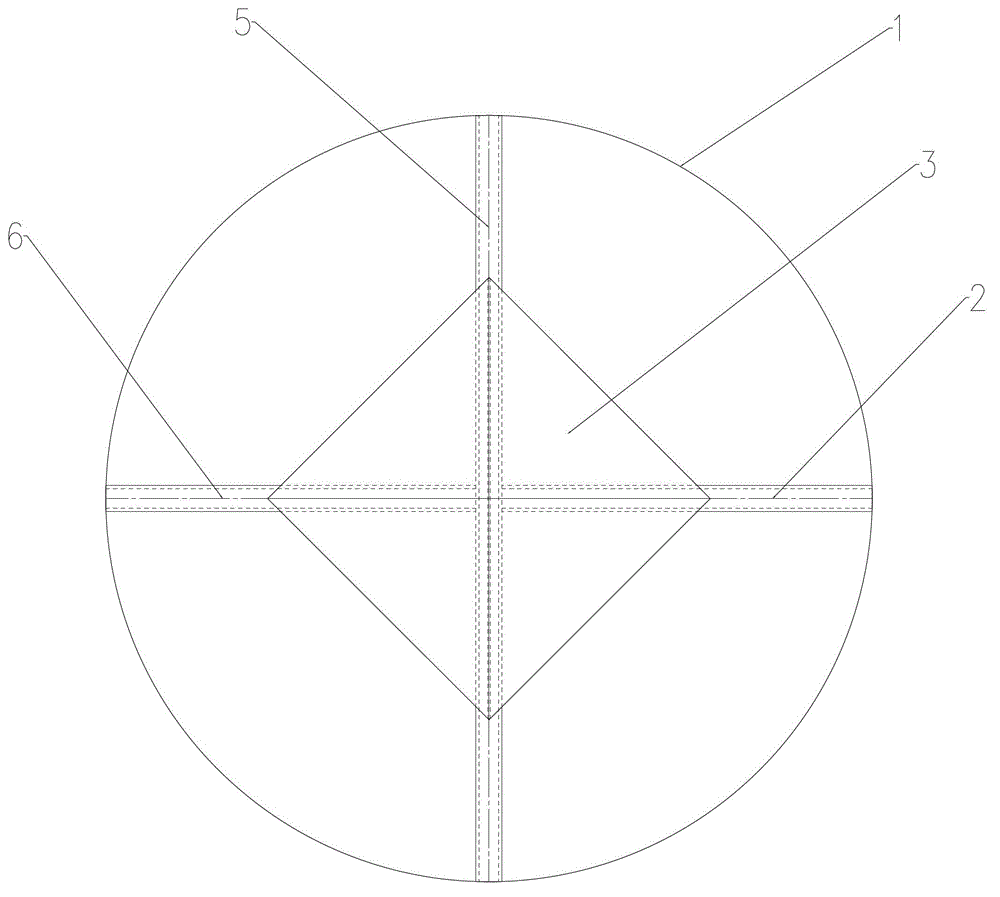

[0011] Such as Figure 1~2 As shown, the present invention mainly includes a warehouse body 1, a cross reinforcing pipe 2, a shroud 3 and a flow-aiding air cushion 4.

[0012] The bin body 1 is a funnel structure with a large top and a small bottom. The cross reinforcement tube 2 is located in the bin body 1. The four ends of the cross reinforcement tube 2 are welded to the inner wall of the bin body 1, which helps to increase the bearing capacity of the inner wall and prevent the inner wall from bulging under pressure. out of shape. The shroud 3 is a regular quadrangular pyramid, and the bottom of the shroud 3 is welded on the cross reinforcing pipe 2 . The center of the shroud 3 and the center of the cross reinforcing pipe 2 are on the same straight line. The shroud 3 can bear the weight of most of the mineral powder, so that the interaction force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com