High-efficiency fruit and vegetable pulping machine

A technology of a beating machine and a pulp outlet, which is applied in juice extraction, food science, application and other directions, can solve the problems of reducing the service life of the beating machine, affecting the work efficiency, affecting the beating quality, etc., to ensure normal and stable operation and high beating efficiency. , the effect of beating evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

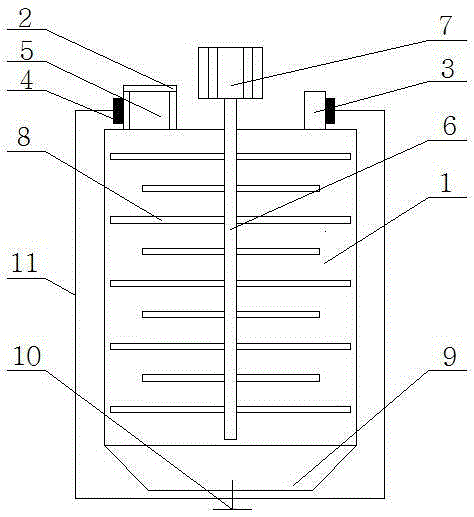

[0015] Example: such as figure 1 As shown, the present invention provides a high-efficiency vegetable beating machine, which includes a cavity 1, a feed inlet 2 and a liquid inlet 3 are respectively provided on both sides of the top of the cavity 1, and a V-shaped slurry outlet 9 is provided at the bottom of the cavity 1. The bottom of the V-shaped pulp outlet 9 is provided with a pressure sensing valve 10, the outer wall of the feed port 2 and the liquid inlet 3 are provided with a flow controller 4, the center of the cavity 1 is provided with a rotating shaft 6, and one end of the rotating shaft 6 extends into the cavity 1 At the bottom, the other end of the rotating shaft 6 is connected to the motor 7 , and the outer wall of the rotating shaft 6 is provided with a number of stirring blades 8 .

[0016] Further, in order to facilitate the material to enter the cavity 1, the inner wall of the feed port 2 is provided with a guide hole 5; in order to enhance the beating perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com