Flexible and efficient unstacking robot system for bagged material

A robot system and robot technology, applied in the direction of unstacking of objects, stacking of objects, manipulators, etc., can solve the problems of increasing production management costs, high labor intensity of workers, and high rate of industrial accidents, so as to improve working conditions and increase production. Efficiency, the effect of avoiding personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

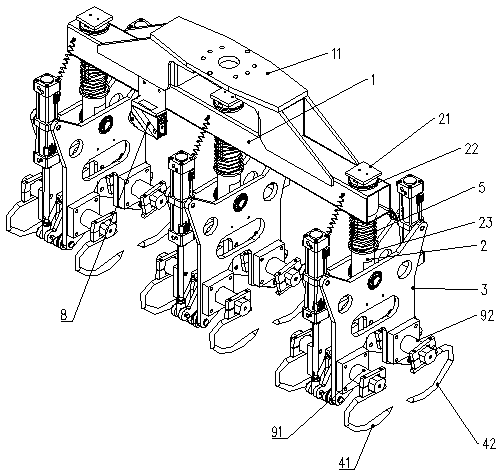

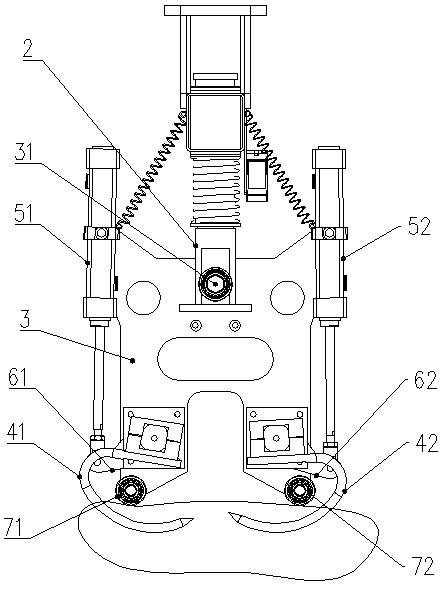

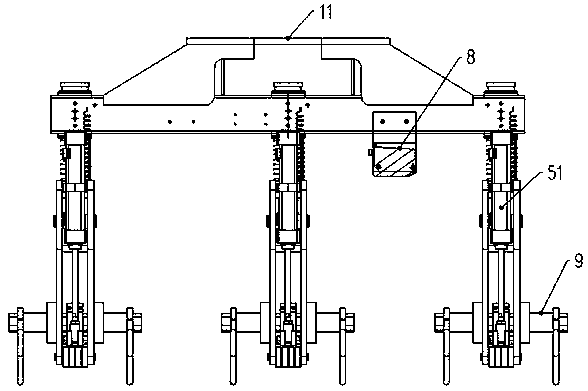

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0029] Such as Figure 4 As shown, a flexible and efficient depalletizing robot system for bagged materials, including a robot base 201, a robot 202, a feeding box 203, a bag breaking saw blade 205, an end effector 206, a pallet positioning block 207, a photoelectric bracket 208, and a guard net 209 And waste bag collection box 211.

[0030] The robot 202 is installed on the robot base 201 , and the end effector 206 is installed at the end of the robot arm of the robot 202 .

[0031] A safety sensor is installed on the photoelectric support 208 to avoid personnel from entering during the working hours of the whole system, causing accidents. The protective net 209 provides necessary mechanical protection to the working area to prevent personnel from entering and improve safety.

[0032] The tray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com