Robot end effector suitable for conveying compact-space bagged materials

A technology of end effectors and robots, which is applied in the stacking of objects, unstacking of objects, conveyors, etc., can solve the problems of increased production management costs, high labor intensity of workers, and high rate of work-related accidents, so as to improve working conditions, Occupies a small space and avoids personal accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

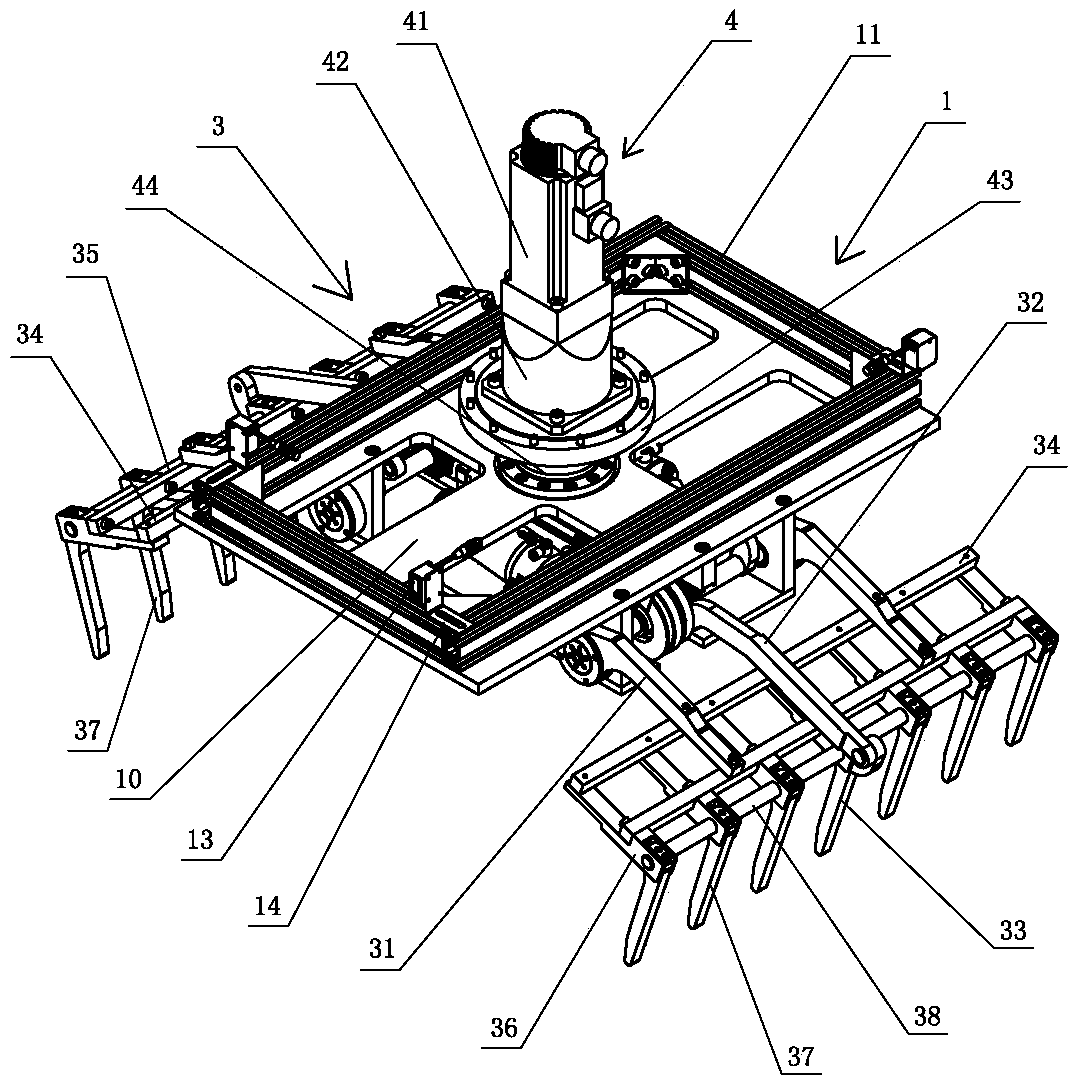

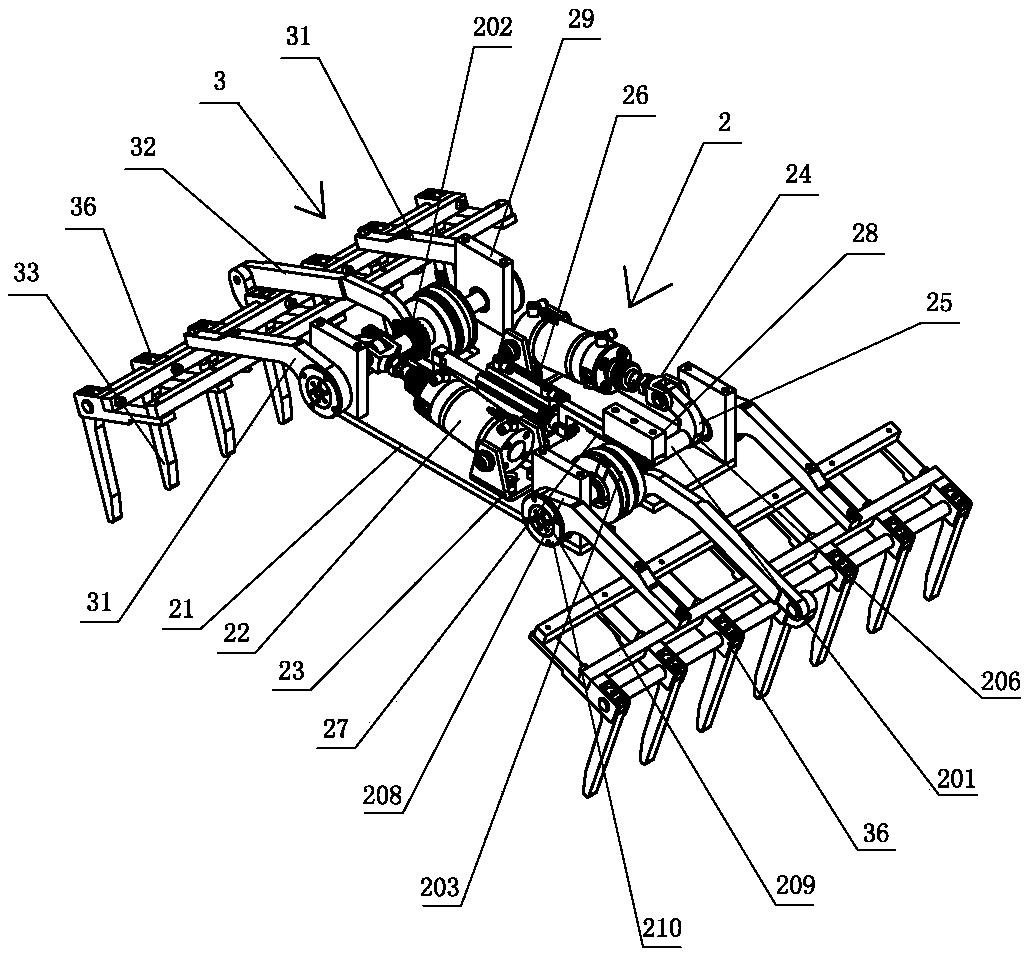

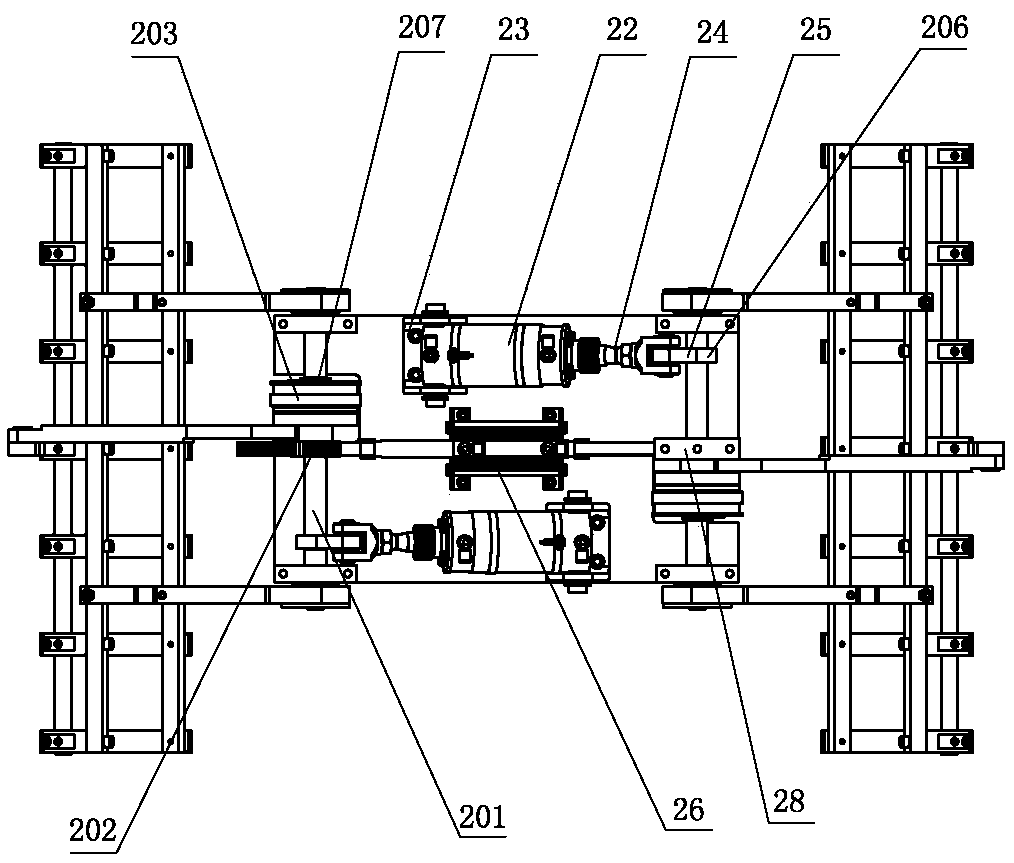

[0037] like Figures 1 to 6As shown, a robot end effector adapted to handling bagged materials in a compact space includes a frame assembly 1, a swing assembly 2, a grasping assembly 3 and a servo assembly 4. The frame assembly 1 is used to support the swing assembly 2, grasp Component 3, servo component 4; frame body component 1 includes upper fixed plate 10, profile 11, fixed block 12, distance sensor 13, distance sensor bracket 14, fixed block 15; swing component 2 includes supporting plate 21, gripping tooth cylinder 22, Cylinder flange 23, Y joint 24, winding arm connecting rod 25, swing tooth cylinder 26, rack 27, rack guide plate 28, fixed plate 29, winding arm shaft 201, clutch gear 202, electromagnetic clutch 203, first bearing , cylinder connector, key A206, key A, spacer 208, large bushing 209, expansion sleeve 210, second bearing; grabbing assembly 3 includes swing rod 31, connecting rod 32, connecting rod gripping teeth 33, upper connecting beam 34. The lower con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com