Multi-stage size beating device for textile size

A textile pulp, multi-stage technology, applied in the direction of grain processing, etc., can solve the problems of poor connection, insufficient beating of pulp, and inability to fully play twice broken, etc., to achieve simple structure, good realization effect, The effect of improving the fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

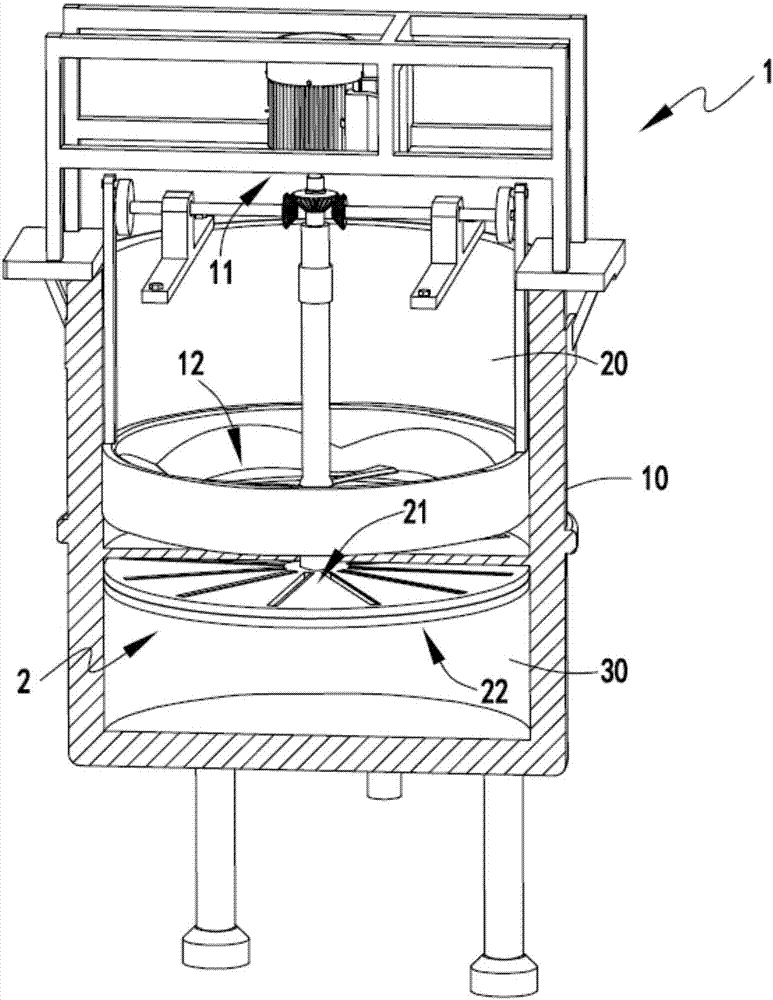

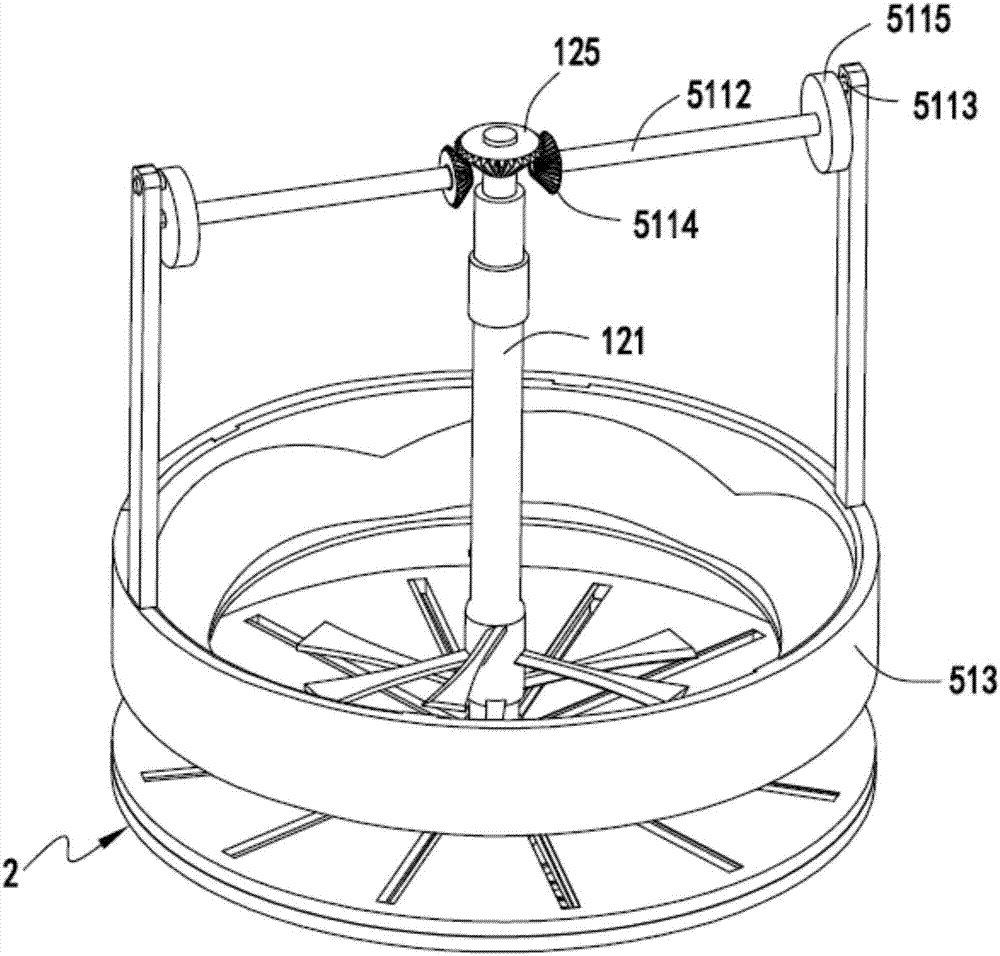

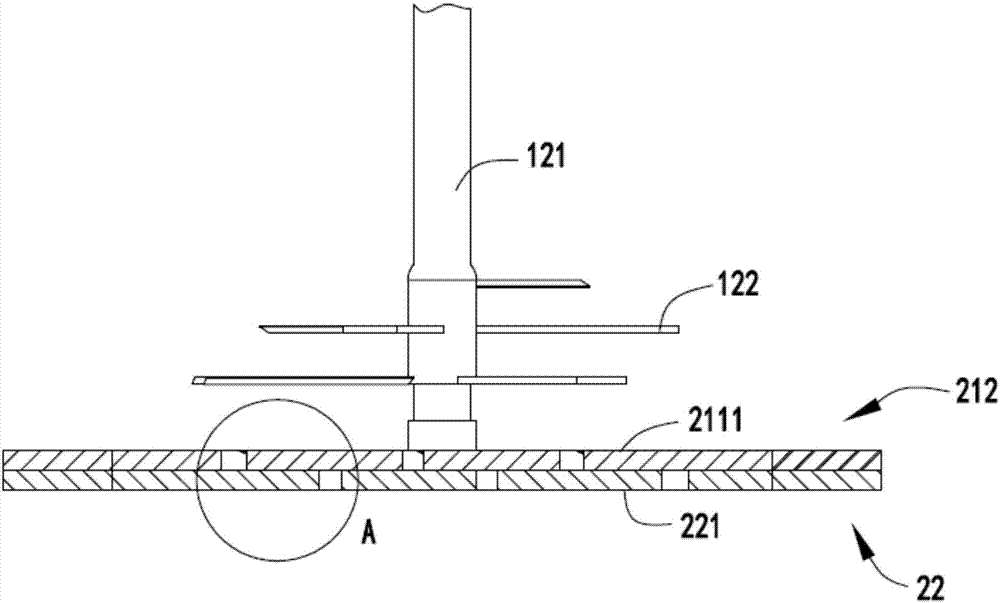

[0042] figure 1 Schematic diagram of the internal structure of the textile pulp multi-stage beating equipment, figure 2 The structure diagram of the crushing mechanism and the toggle device, image 3 Part of the structure diagram when the textile pulp multi-stage beating equipment is closed, Figure 4 Part of the structure diagram when the textile pulp multi-stage beating equipment is opened, Figure 5 It is a schematic diagram of the enlarged structure when the crosscutting device is closed, Image 6 Is the enlarged structure diagram when the crosscutting device is opened, Figure 7 Is the structural diagram of the crosscutting mechanism, Figure 8 Is an enlarged schematic diagram of the arc waist groove, Picture 9 Is the structural diagram of the toggle, Picture 10 Is the structural diagram of the transmission assembly b, Picture 11 Is the structure diagram of the crushing mechanism, Picture 12 Is the structure diagram of the blanking device, Figure 13 It is a schematic di...

Embodiment 2

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 with Figure 13 As shown, the components that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The second embodiment is different from the first embodiment in that it also includes a toggle mechanism 5 arranged on the side of the crushing mechanism 12, and the toggle mechanism 5 includes a mechanism for transferring the slurry on the inner side of the beating bucket 10 to The middle dialing device 51 includes a transmission assembly a511 and a transmission assembly b512, and a dial 513 fixedly connected to the ends of the transmission assembly a511 and the transmission assembly b512.

[0057] Further, the agitating shaft 121 is provided with be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com