Dual-rotation direction blade hole-blade soybean milk machine

A dual-rotation, soybean milk machine technology, applied in milk substitutes, grain processing, beverage preparation devices, etc., can solve problems such as reducing the degree of contact between the slurry and the blade, reducing the speed of hitting the slurry particles, and reducing the probability of collision. , to achieve the effect of making the finishing effect thoroughly, increasing the collision speed and collision probability, and reducing the collision probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

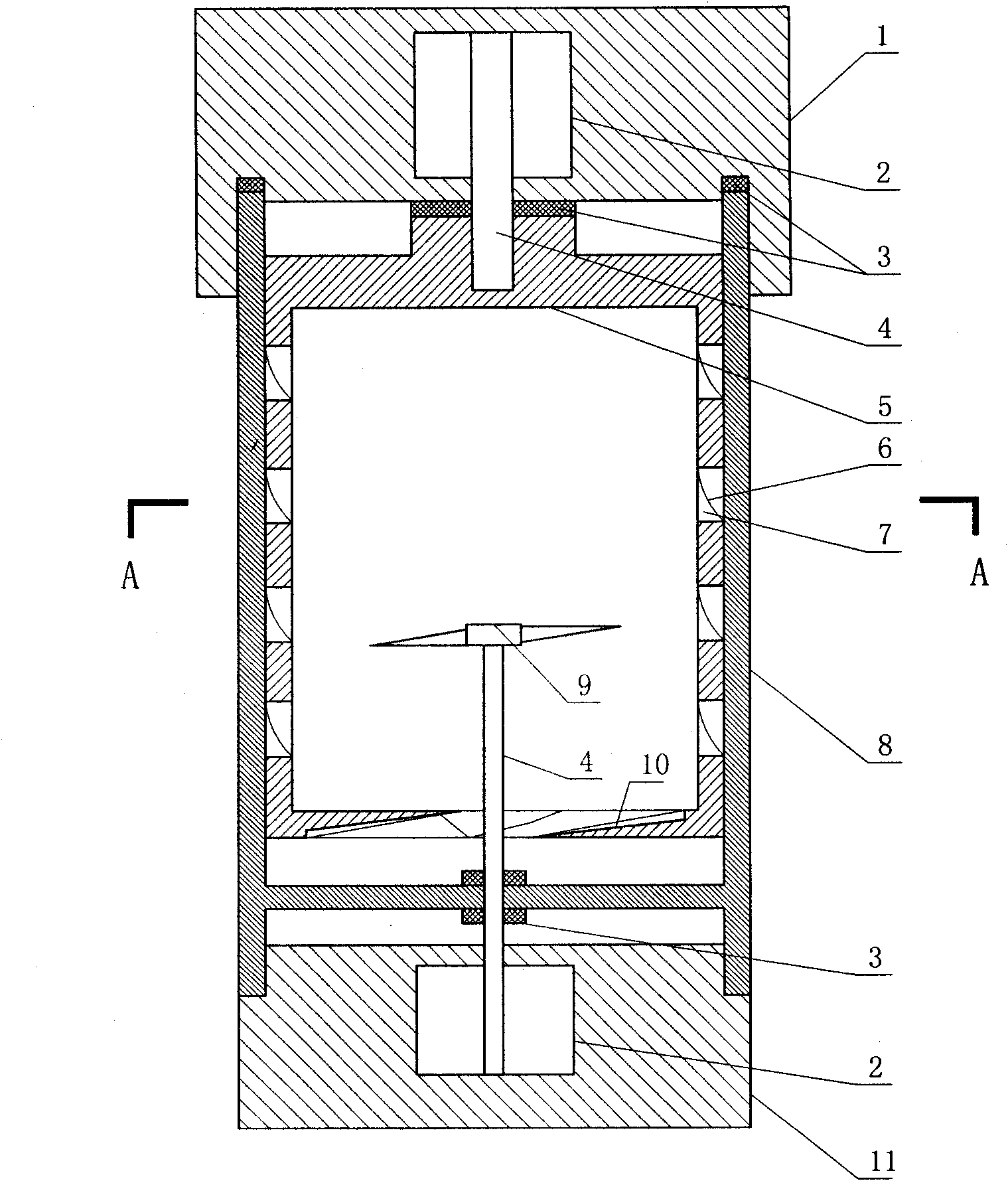

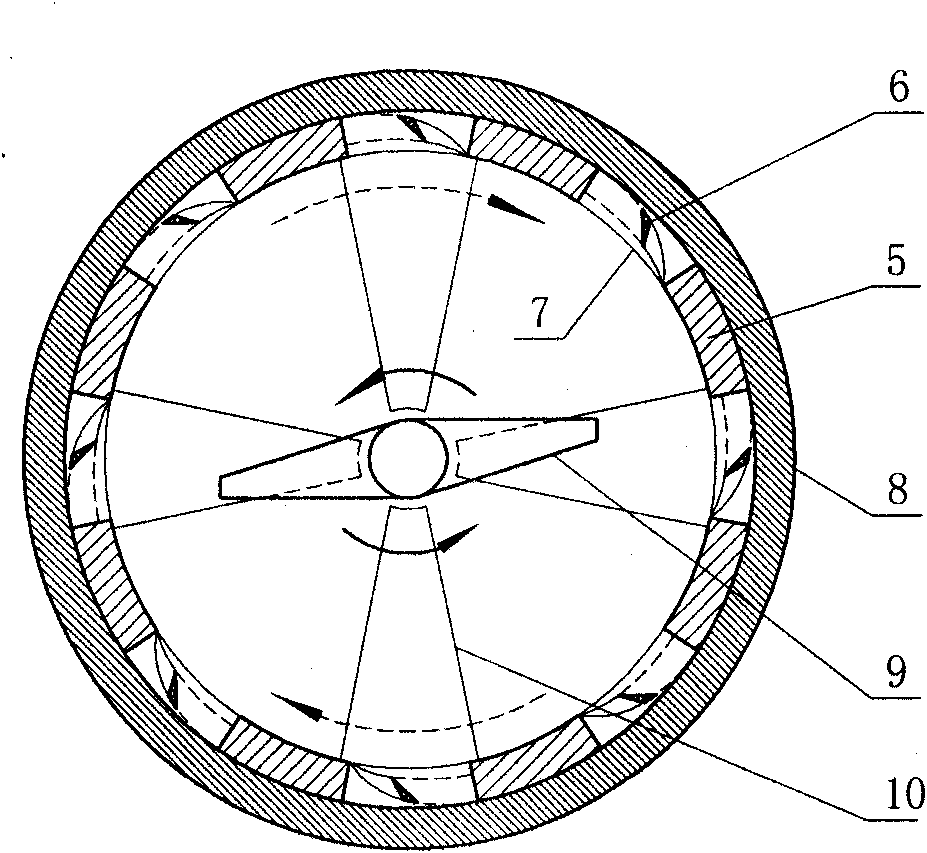

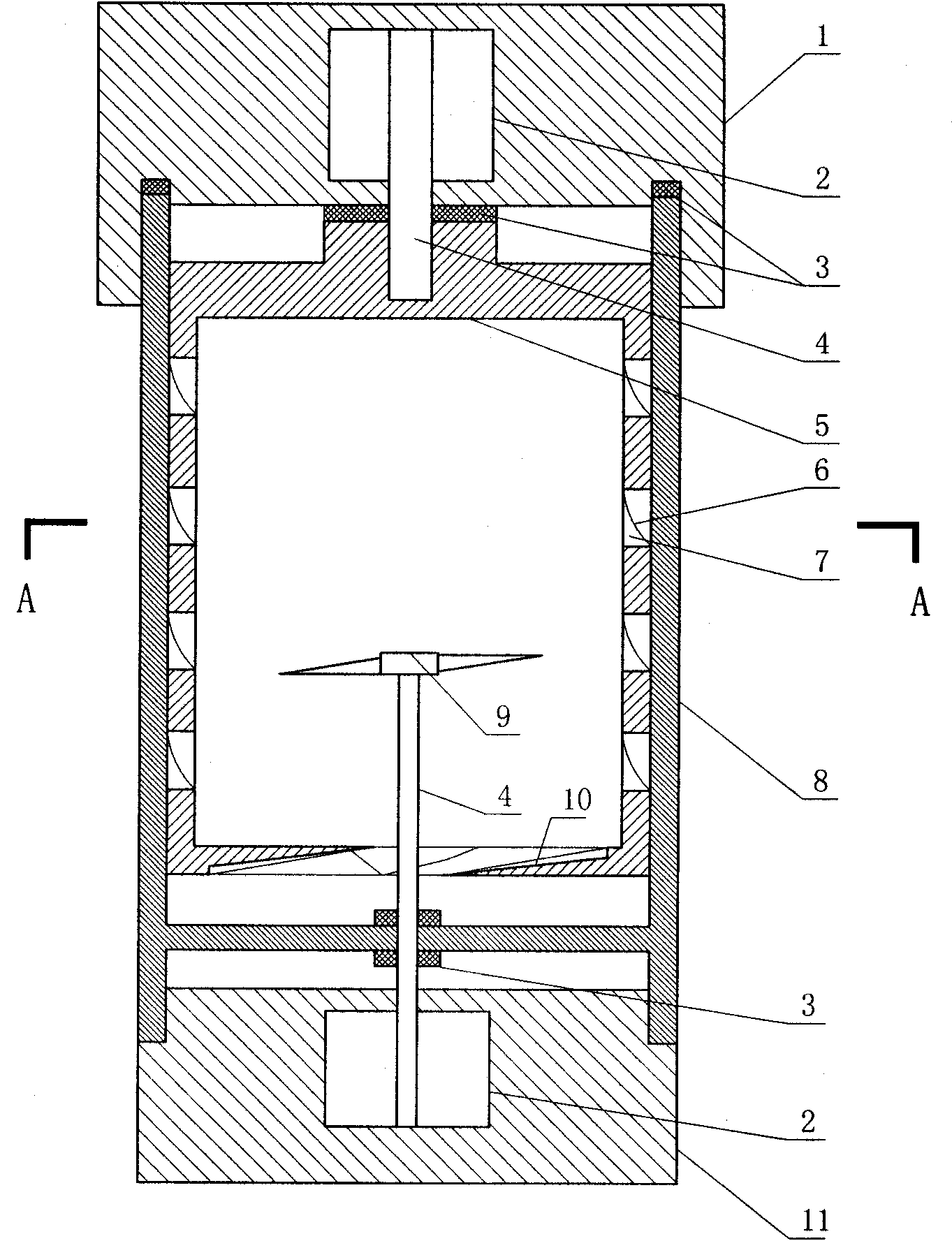

[0014] The double-rotating blade hole blade soymilk machine consists of a top cover 1, a motor 2, a sealing ring 3, a rotating shaft 4, a sleeve 5, a hole blade 6, a grinding hole 7, a barrel 8, a main blade 9, a bottom blade 10 and a base 11 composition.

[0015] The barrel 8 is a cylinder with an open upper end and a shaft hole in the center of the lower bottom. The top cover 1 and the base 11 are respectively arranged on the top and bottom of the barrel 8 and are threadedly combined with the barrel 8 respectively. A sealing ring 3 is stuck on the top cover 1 and the base 11 at the junction. The sleeve 5 is a cylinder with a closed upper end and an open lower end. The lower end of the sleeve 5 has four bottom blades 10 which are integrated with the sleeve 5 and evenly distributed along the circumference of the sleeve 5. On the side of the sleeve 5 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com