Paper making beater

A beating machine and machine body technology, applied in the field of papermaking machinery, can solve the problems of low beating efficiency, low work efficiency, and small beating volume, and achieve the effects of improving beating efficiency, good beating effect, and large beating volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

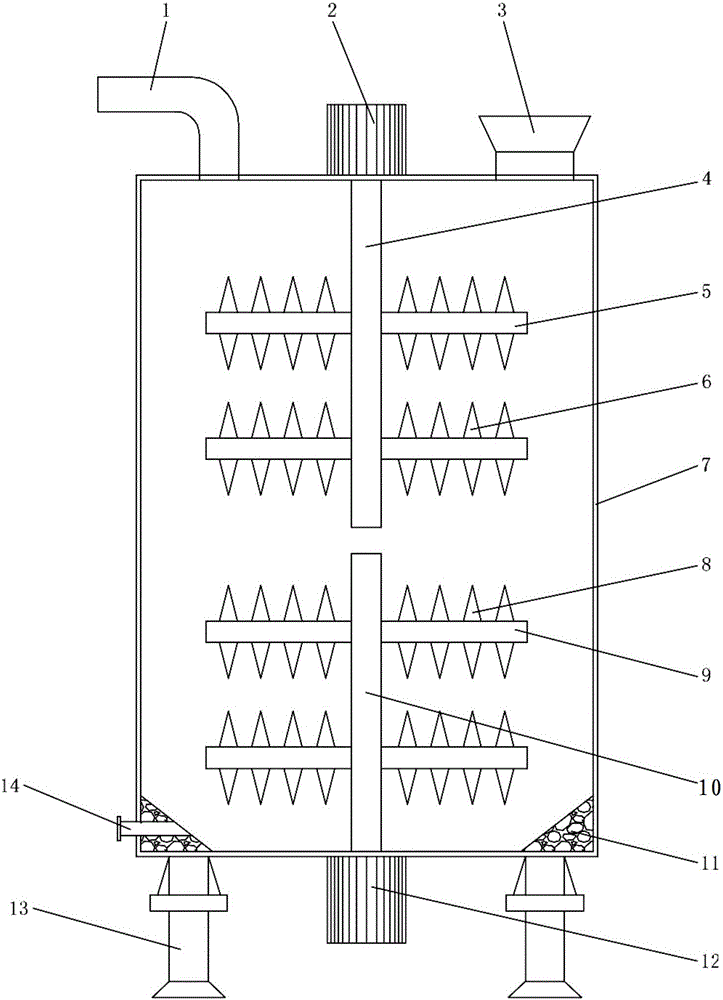

[0007] Such as figure 1 As shown, the papermaking beater is mainly composed of a body 7, a motor 2 (12), a knife rest 5 (9), a knife shaft 4 (10) and a blade 6 (8).

[0008] The top of body 7 offers slurry inlet 3 and connects water inlet pipe 1, and the inner bottom of body 7 is provided with slope 11, offers slurry outlet 14 at slope 11 places. The bottom of the body 7 is provided with height-adjustable legs 13 . The upper part of the body 7 inner center is equipped with an upper motor 2, the output shaft of the upper motor 2 is connected to the vertical upper knife shaft 4, and several upper knife rests 5 are evenly distributed around the outer wall of the upper knife shaft 4, and the upper knife rest 5 There are several groups up and down, and the upper knife rest 5 is provided with blades 6 . The lower part of the body 7 inner center is equipped with a lower motor 12, the output shaft of the lower motor 12 is connected to the vertical lower knife shaft 10, and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com