Sliding Precast Forming Machine

A technology of prefabricated components and forming machines, which is applied in the direction of ceramic forming machines and manufacturing tools, which can solve the problems of low production efficiency, occupying the molding cavity of equipment, and inability to produce concrete prefabricated components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

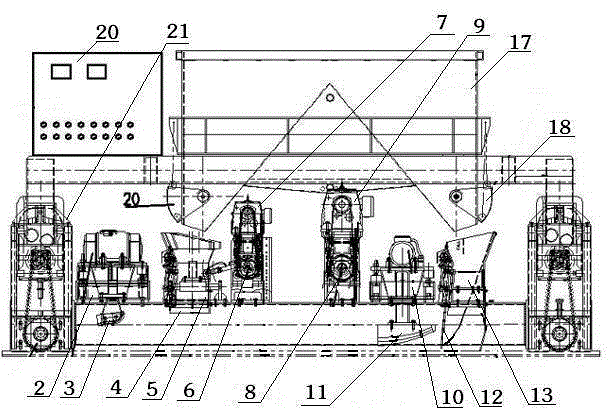

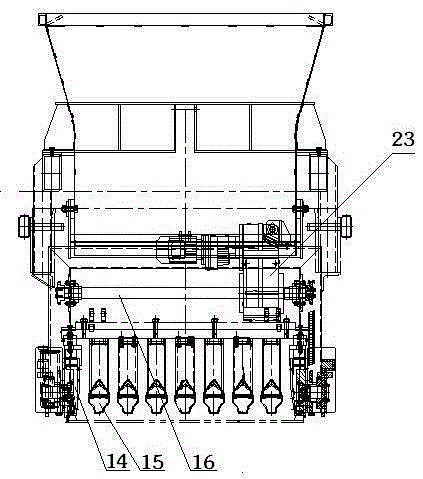

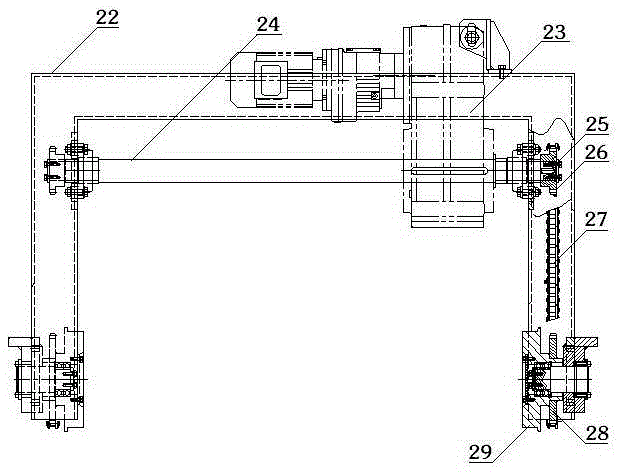

[0010] Referring to the accompanying drawings, a sliding prefabricated component forming machine includes a frame 1, a first vibrator 2, a rear vibrating plate 3, a first material limiting plate 4, a rear distribution box 5, a material box drive shaft 6, a material Box drive shaft motor 7, mold drive shaft 8, mold drive shaft motor 9, second vibrator 10, front vibrating plate 11, second material limiting plate 12, front distribution box 13, side template 14, mandrel 15, mold The connection beam 16, the main material box 17, the front material door 18 of the main material box, the rear material door 19 of the main material box and the power distribution cabinet 20 are characterized in that: the front and rear sides of the frame 1 are respectively provided with a walking device 21, Described walking device 21 is provided with walking frame 22, and walking frame 22 is provided with variable frequency deceleration motor 23, and on the variable frequency deceleration motor 23, wears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com