Shoe upper beating device for shoemaking

A technology for shoe uppers and shoes, which is applied in footwear, applications, beating machines, etc., can solve the problems of low beating efficiency, high labor intensity of workers, and hand injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

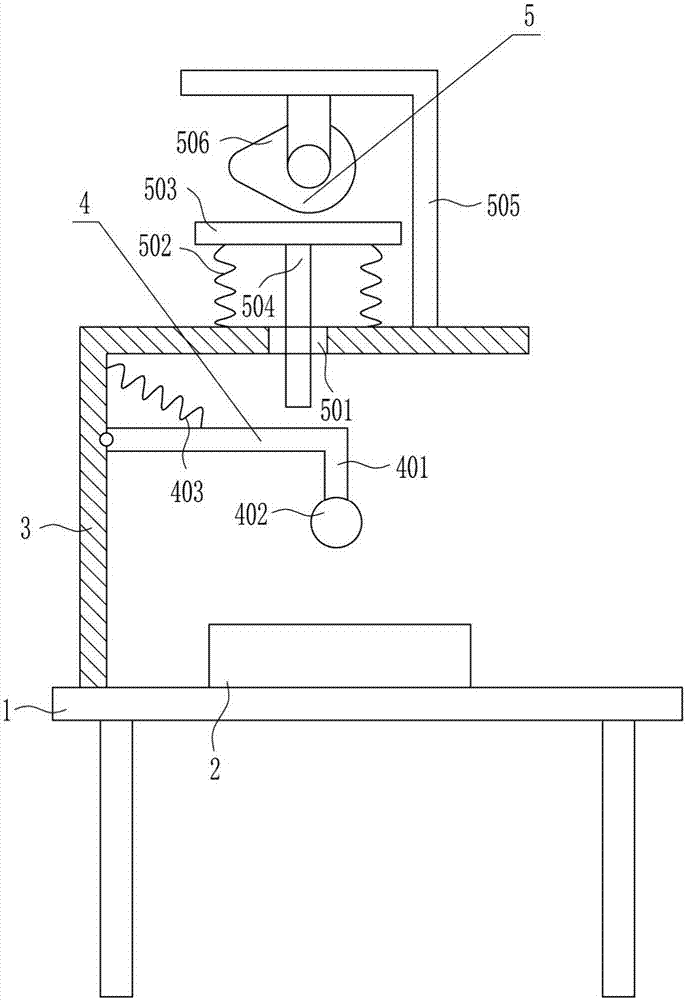

[0027] A kind of shoe upper beating device for making shoes, such as Figure 1-3 As shown, it includes a workbench 1, a placement platform 2, a first 7-shaped plate 3, a beating device 4 and a driving device 5. The top of the workbench 1 is connected with a placement platform 2 by bolts, and the workbench 1 on the left side of the placement platform 2 The top is connected with the first 7-shaped plate 3 by bolts, the inner surface of the first 7-shaped plate 3 is provided with a beating device 4 , and the top of the first 7-shaped plate 3 is provided with a driving device 5 .

Embodiment 2

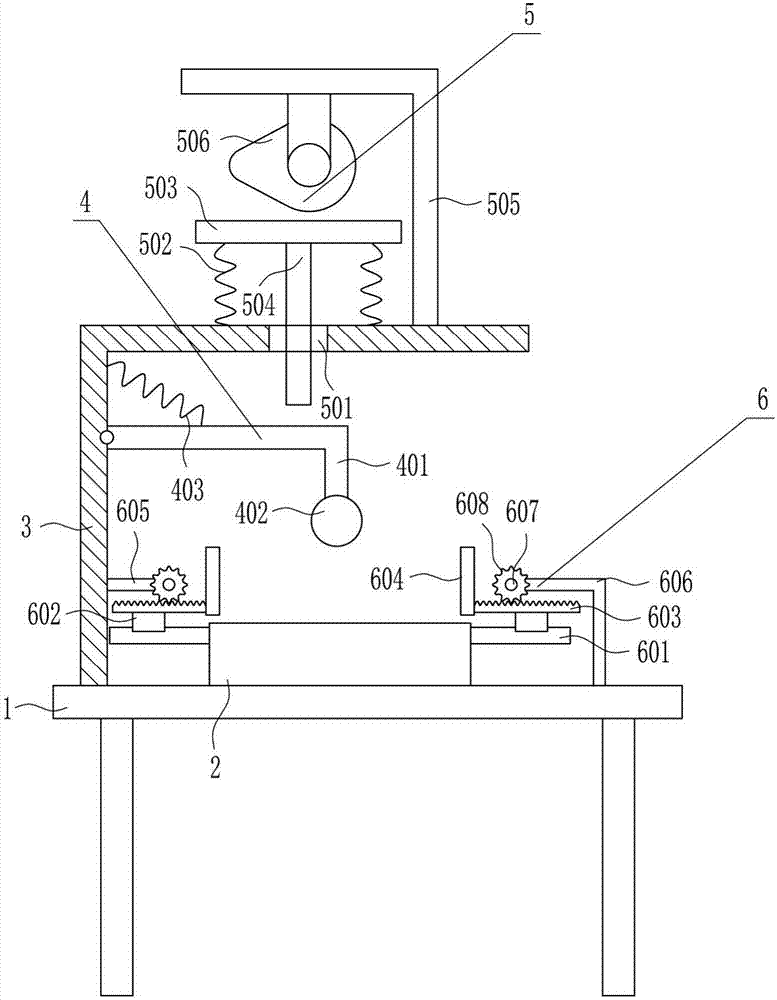

[0029] A kind of shoe upper beating device for making shoes, such as Figure 1-3 As shown, it includes a workbench 1, a placement platform 2, a first 7-shaped plate 3, a beating device 4 and a driving device 5. The top of the workbench 1 is connected with a placement platform 2 by bolts, and the workbench 1 on the left side of the placement platform 2 The top is connected with the first 7-shaped plate 3 by bolts, the inner surface of the first 7-shaped plate 3 is provided with a beating device 4 , and the top of the first 7-shaped plate 3 is provided with a driving device 5 .

[0030] The beating device 4 includes a connecting plate 401, a beating block 402 and a first spring 403, the left side of the connecting plate 401 is hingedly connected with the inner side of the first 7-shaped plate 3 through a hinge member, and the right side of the connecting plate 401 bottom is welded with a beating spring 403. Block 402 , a first spring 403 is connected between the left side of the...

Embodiment 3

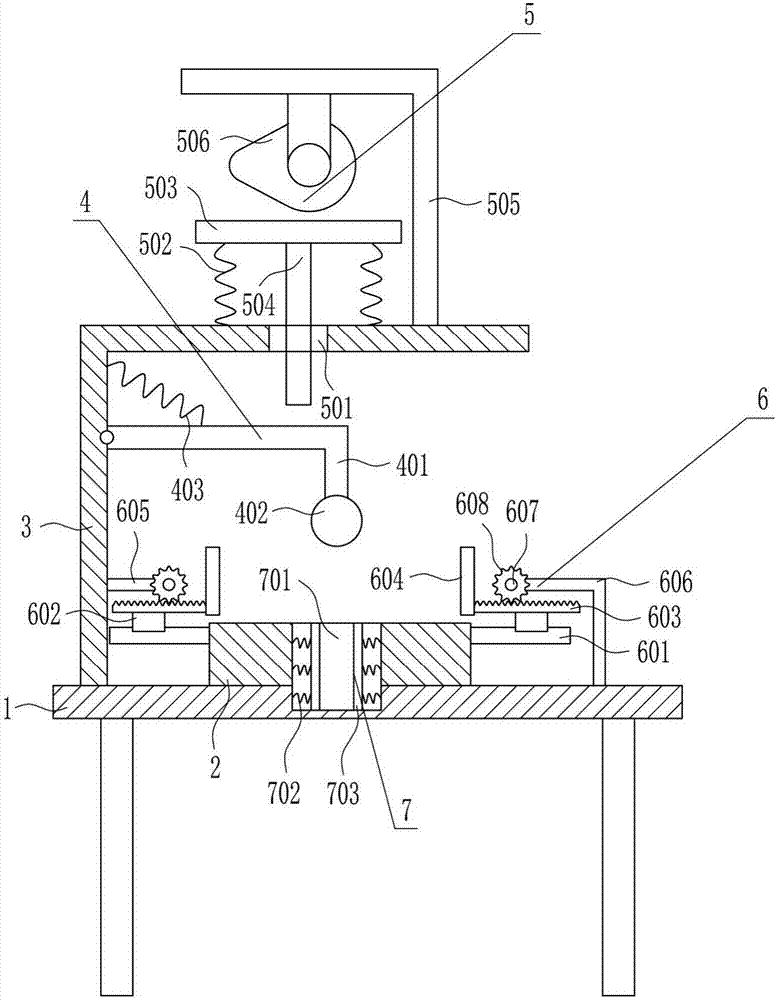

[0032] A kind of shoe upper beating device for making shoes, such as Figure 1-3As shown, it includes a workbench 1, a placement platform 2, a first 7-shaped plate 3, a beating device 4 and a driving device 5. The top of the workbench 1 is connected with a placement platform 2 by bolts, and the workbench 1 on the left side of the placement platform 2 The top is connected with the first 7-shaped plate 3 by bolts, the inner surface of the first 7-shaped plate 3 is provided with a beating device 4 , and the top of the first 7-shaped plate 3 is provided with a driving device 5 .

[0033] The beating device 4 includes a connecting plate 401, a beating block 402 and a first spring 403, the left side of the connecting plate 401 is hingedly connected with the inner side of the first 7-shaped plate 3 through a hinge member, and the right side of the connecting plate 401 bottom is welded with a beating spring 403. Block 402 , a first spring 403 is connected between the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com