Acorn starch as well as preparation method and application thereof

An acorn starch and acorn kernel technology, which is applied in the field of food processing, can solve the problems of environmental pollution, high pressure on wastewater treatment, large water consumption and wastewater generation, and achieves water saving, small slurry fineness, and water consumption. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

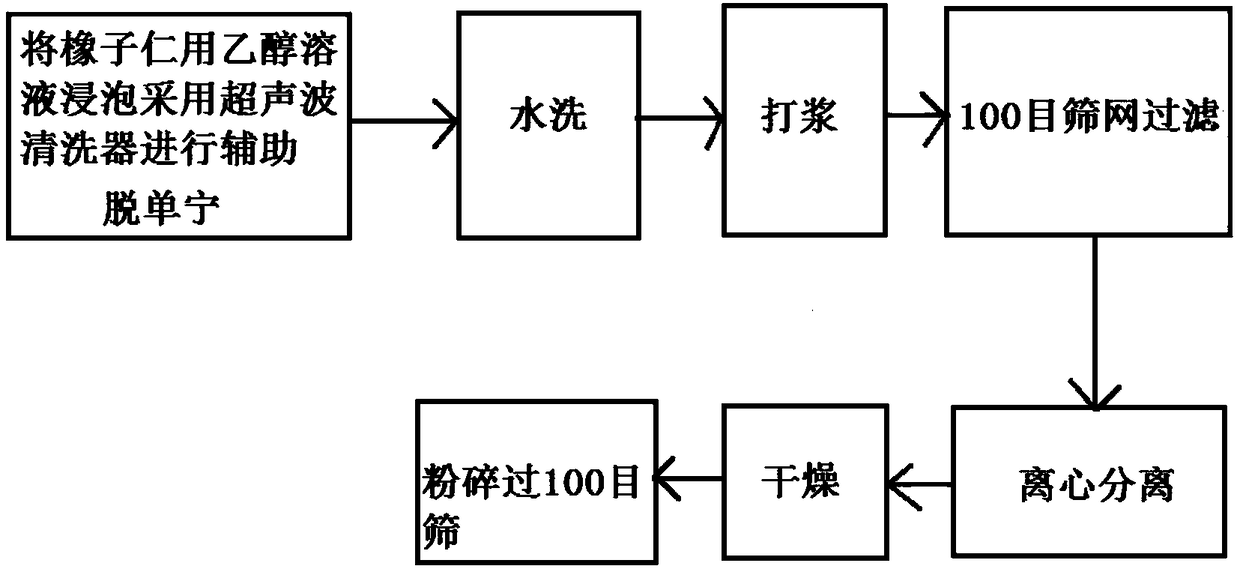

[0038] A method for preparing acorn starch, comprising the following steps: soaking acorn kernels in an ethanol solution and using an ultrasonic cleaner to perform an auxiliary tannin removal step, a water washing step, a beating step, a 100-mesh screen filtering step, a circulating water washing step, and drying The step of crushing and passing through a 100-mesh sieve to obtain acorn starch.

[0039] The beneficial effects of this embodiment are as follows:

[0040] (1) The efficiency of removing tannin is high, the water consumption is less, water resources are saved, no toxic and harmful chemicals are used in the production process, and it meets the food safety requirements.

[0041] (2) Since tannin has more polar groups, it has strong polarity and is soluble in hydrophilic organic solvents. Ultrasonic technology uses the mechanical effect, cavitation effect and thermal effect of ultrasonic waves to accelerate The leaching of tannins in acorn kernels into ethanol was pre...

Embodiment 2

[0044] A preparation method of acorn starch, comprising the following steps:

[0045] (1) Soak the acorn kernels in ethanol solution and use an ultrasonic cleaner to assist in removing tannins: take the preferred dry acorn kernels, wash them with water to remove the dust outside the acorn kernels, in g / mL, and use a material-to-liquid ratio of 1 :20 Add ethanol solution with a volume fraction of 30%, seal with plastic wrap, and use an ultrasonic cleaner to assist, each time at 30±1°C for 50±1min to remove tannin, repeat this step for 3 times, then enter the water washing step ;

[0046] (2) Washing step: repeatedly rinse the acorn kernels with water until there is no ethanol residue on the surface, and then beating after washing;

[0047] (3) Beating step: use a soymilk machine to crush and beat the acorn kernels after removing tannins in g / mL according to the material-to-water ratio of 1:2;

[0048] (4) 100 mesh sieve filtration step: then the slurry is filtered through a 1...

Embodiment 3

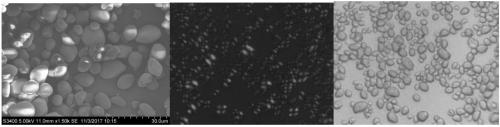

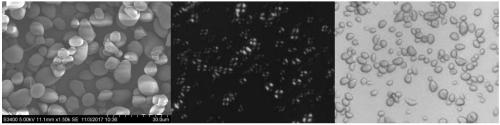

[0059] In order to verify the effect of immersing acorn kernels in ethanol solution and using an ultrasonic cleaner to assist in removing tannins, the acorn starch obtained in Example 2 was compared with the acorn starch obtained by soaking in hot water, soaking in alkaline washing, and ultrasonic method , except that the steps of removing tannins are different, the subsequent steps are the same.

[0060] Hot water immersion method: wash to remove the dust outside the acorn kernels, soak in hot water at 45±1℃ for 48±1h according to the material-to-water ratio of 1:30 (g / mL), and change the water every 8h. Then beating (the ratio of material to water is 1:2), and then the slurry is filtered through a 100-mesh screen to obtain a fineness of 100-mesh slurry. Add an appropriate amount of water to the slurry, stir well, centrifuge at 3000r / min for 5±1min, and remove the rinsing slurry. Repeat the centrifugal separation step 3 times in this way to obtain wet acorn starch. The wet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com