Method for production of sulfuric acid by flue gas desulfurization and for sulfuric acid purification and device thereof

A technology for flue gas and sulfuric acid, applied in the direction of combination device, separation method, chemical instrument and method, can solve the problems of difficult separation, large ozone consumption and electricity consumption, high operating cost, and achieve high oxidation efficiency and oxidation time. Long, block-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

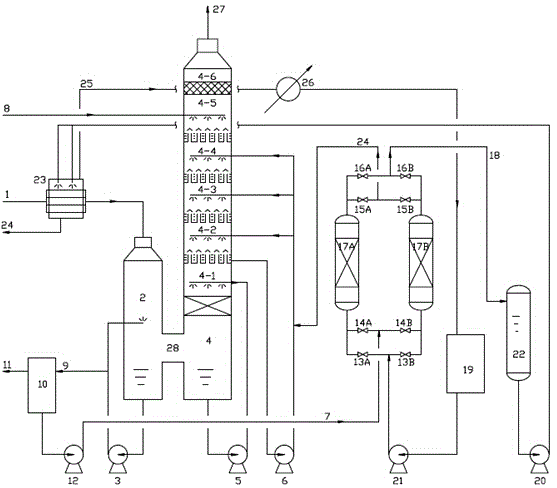

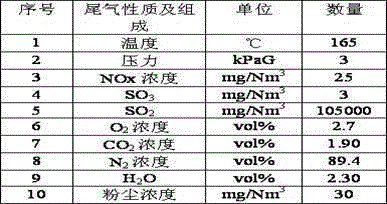

[0042] The flue gas composition of a catalytic cracking catalyst regenerated is shown in Table 1.

[0043] Table 1 Composition of flue gas regenerated from a catalytic cracking catalyst.

[0044]

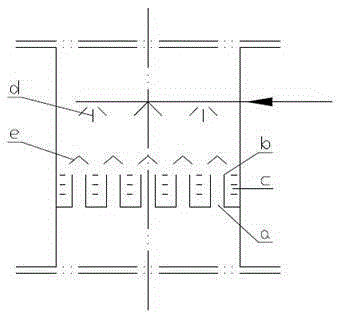

[0045] Operating conditions of the present invention: (1) The dedusting and quenching tower adopts a turbulent liquid-gas ratio of 7.0L / m 3 ; (2) The deep dust removal unit 4-1 of the desulfurization tower is filled with packing, and the desulfurization unit adopts spray absorption, and the operating liquid-gas ratio of the deep dust removal unit is 3.0L / m 3 , the desulfurization unit first, second and third cycle desulfurization liquid gas ratio is 4.0L / m 3 ; (3) The absorption solution is ferric chloride solution, in which Fe 3+ The mass concentration is 3.0%; (4) The pH of the absorption liquid in the liquid holding tank of the dedusting and quenching tower is 1.0~2.0; (5) There are two absorption liquid regeneration towers, switching operation, and the commercially availabl...

Embodiment 2

[0048] The flue gas composition of adsorbent regeneration in a S zorb unit is shown in Table 2.

[0049] Table 2 Composition of flue gas from adsorbent regeneration in a certain S-zorb device.

[0050]

[0051] The operating conditions of the present invention: (1) The dedusting and quenching tower adopts a Venturi composition gas-liquid mass transfer unit, and the liquid-gas ratio is 3.0L / m 3 ; (2) The deep dust removal unit 4-1 of the desulfurization tower is filled with packing, and the desulfurization unit adopts spray absorption, and the operating liquid-gas ratio of the deep dust removal unit is 3.0L / m 3 , the desulfurization unit's primary, secondary and tertiary cycle desulfurization liquid-gas ratios are all 2.0L / m 3 ; (3) The absorption solution is ferric chloride and H 2 o 2 The mixed solution, where Fe 3+ Mass concentration 3.0%, H 2 o 2 The mass concentration is 1.0%; (4) The pH of the absorption liquid in the liquid holding tank of the dedusting quenchin...

Embodiment 3

[0054] The flue gas composition of a coal-fired boiler is shown in Table 3.

[0055] Table 3 Flue gas composition of a coal-fired boiler.

[0056]

[0057] Operating conditions of the present invention: (1) The dedusting and quenching tower adopts turbulence, and the liquid-gas ratio is 8.0L / m 3; (2) The deep dust removal unit 4-1 of the desulfurization tower is filled with packing, and the desulfurization unit adopts spray absorption, and the operating liquid-gas ratio of the deep dust removal unit is 3.0L / m 3 , the desulfurization unit first, second and third cycle desulfurization liquid gas ratio is 4.0L / m 3 ; (3) The absorption solution is ferric chloride and H 2 o 2 The mixed solution, where Fe 3+ Mass concentration 3.0%, H 2 o 2 The mass concentration is 0.3%; (4) The pH of the absorption liquid in the liquid holding tank of the dedusting and quenching tower is 1.0-2.0; (5) There are two regeneration towers for the absorption liquid, switching operation, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com