Annular flow aerobic granule sludge reactor

A reactor, dissolved oxygen technology, applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. Uniformity and other problems to achieve the effect of improving the utilization rate of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

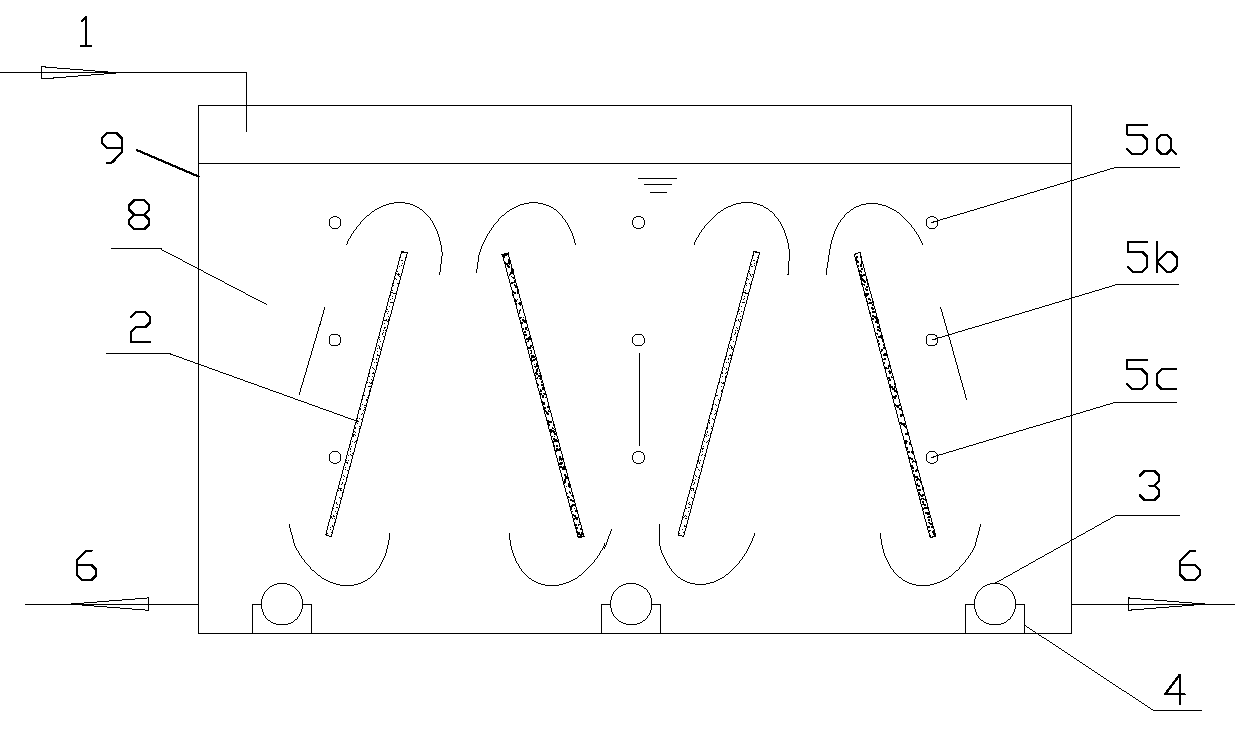

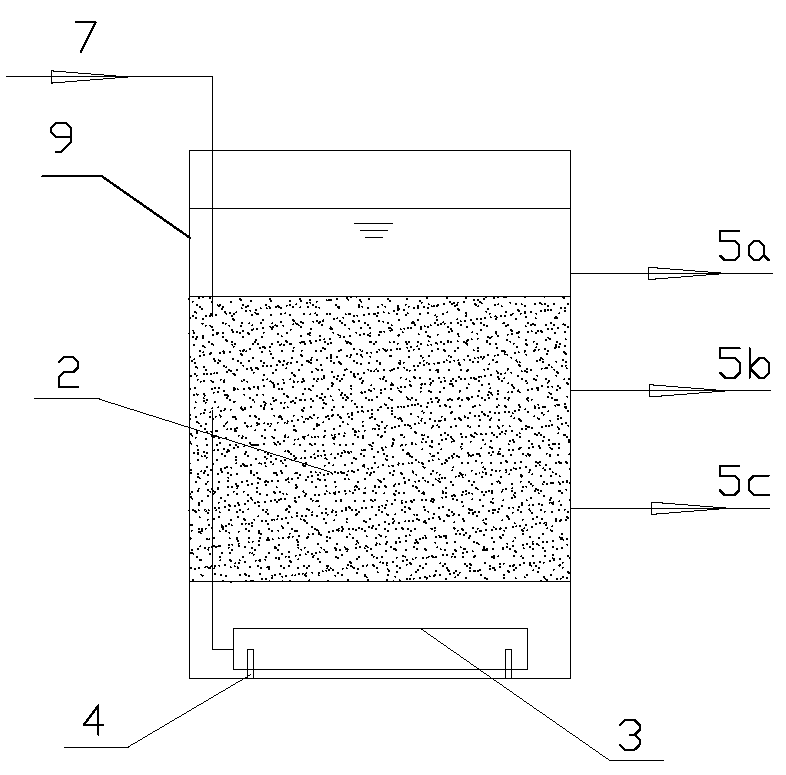

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Depend on figure 1 , 2 As shown, the present invention includes a reactor body and a deflector, and a plurality of deflectors 2 are installed horizontally in an inclined shape in the inner cavity 8 of the reactor body 9, and the reactor inner chamber is divided into a plurality of reaction zones, and the flow guide The two sides of the plate are sealed and connected with the side wall of the reactor body, and the upper and lower ends of two adjacent deflector plates form a reaction liquid channel with different widths. There is a space for liquid circulation between them, forming a reaction zone connected up and down. The bottom of the leftmost and rightmost reaction zones are respectively equipped with tubular aerators 3, and the remaining reaction zones are equipped with tubular aerators every other zone. The reactor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com