Biofilm reactor and method for sewage efficient denitrification

A biofilm reactor, a high-efficiency technology, applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problem that it is difficult to further improve the denitrification capacity, the effluent is difficult to meet the standard stably, and the carbon source is not fully utilized. problems, to achieve the effects of a wide range of treated water, improved utilization of dissolved oxygen, and efficient full-process treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

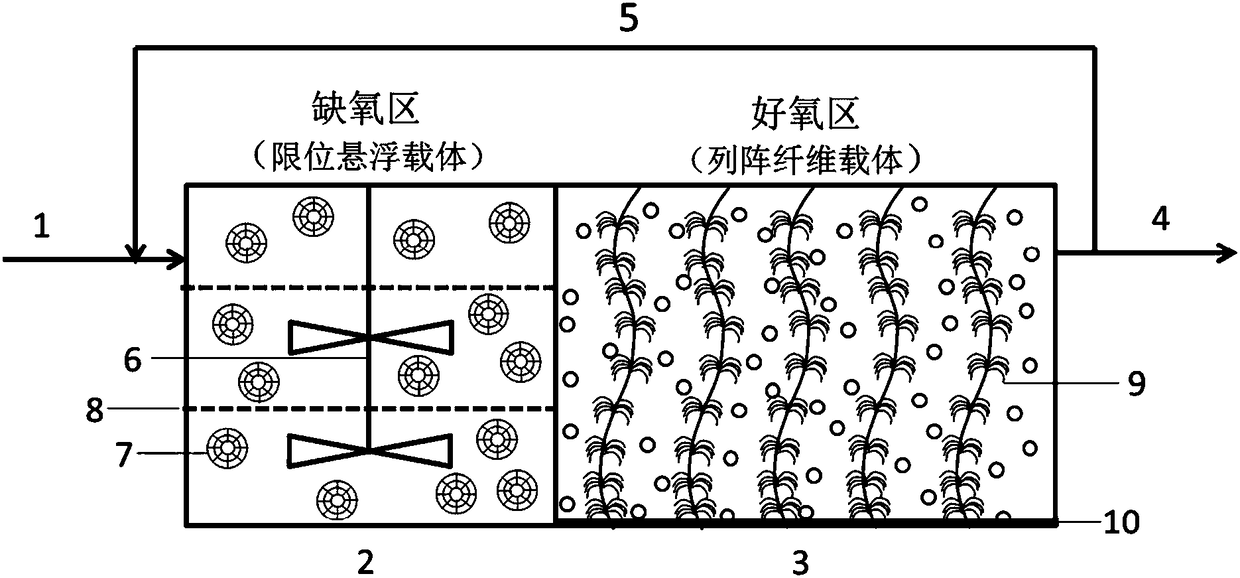

[0031] Example 1 A biofilm reactor for efficient denitrification of sewage

[0032] Such as figure 1 As shown, a biofilm reactor for efficient denitrification of sewage, which includes: water inlet pipe 1, anoxic reaction zone 2, aerobic reaction zone 3, outlet pipe 4, and connection, and return pipe 5, in the aerobic reaction The back end of the zone is connected to the return pipe to make the reaction liquid return to the anoxic reaction zone; in the anoxic reaction zone, there are stirrers 6, limit suspension carriers 7 and layering devices 8; in the aerobic reaction zone, there are array fiber carriers 9 And aeration device 10.

[0033] Among them, the anaerobic reaction zone is filled with suspended filler, and is divided into multiple layers by a partition with holes to limit the filler to a certain area.

[0034]Among them, the upper and lower ends of the array fiber carrier in the aerobic reaction zone are fixed on the top and bottom of the reactor respectively, so t...

Embodiment 2

[0035] Example 2 A biofilm reactor for efficient denitrification of sewage

[0036] On the basis of Example 1, the anaerobic reaction zone is filled with suspended fillers, and is divided into multiple layers (3-5 layers) with a partition with holes. The filler in the anaerobic reaction zone is K-3 filler, and the specific surface area> 800m 2 / m 3 , The distribution rate can reach more than 60%.

[0037] The array fiber carrier in the aerobic reaction zone adopts flexible fiber filler. The main material is aldehyde fiber, and the packing density can reach 50m / m 3 .

[0038] An aeration device is installed at the bottom of the aerobic reaction zone, and step aeration is adopted to divide the aerobic zone into three zones with different aeration intensity.

Embodiment 3

[0040] A treatment method for high-efficiency biological denitrification, using the aforementioned embodiment 2 biofilm reactor for domestic sewage treatment, including:

[0041] (1) Sewage enters the anoxic reaction zone from the water inlet pipe, and the anoxic reaction zone is filled with suspended fillers, and is divided into 5 layers with perforated partitions to limit the fillers to a certain area, so that different biological communities can be formed in different areas Controlled biofilm, and use mechanical stirring to ensure that the filler is evenly distributed in this area;

[0042] (2) After the sewage is treated in the anoxic reaction zone, it enters the aerobic reaction zone. The aerobic reaction zone uses flexible fiber filler, the main material is aldehyde fiber, and the packing density can reach 50m / m 3 ; Fix the upper and lower ends of the reactor on the top and bottom of the reactor respectively, so that it forms a cross-flow array structure with the water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com