Method for preparing lithium-sulfur battery anode based on catalysis of active MnO2

A lithium-sulfur battery and sulfur electrode technology, applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve the problems of high ratio of mass and volume of inactive substances, affecting the practical application of lithium-sulfur batteries, reducing the advantages of lithium-sulfur batteries, etc. , to achieve the effect of suppressing the shuttle effect, facilitating high-rate discharge, and avoiding the loss of active material sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

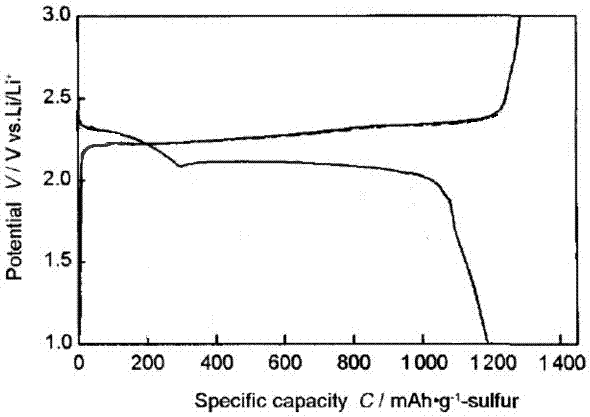

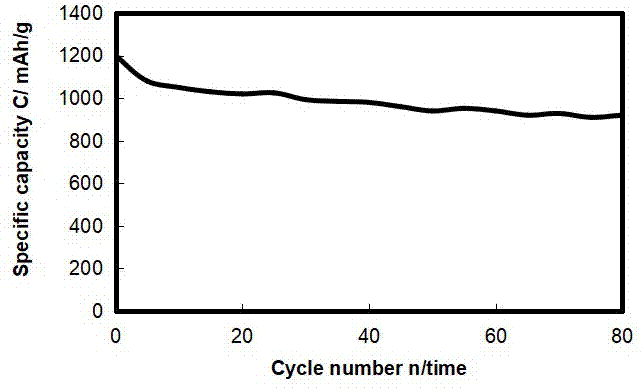

Image

Examples

Embodiment 1

[0012] Preparation of active manganese dioxide: Weigh 108.79g manganese dioxide (produced in Hunan, battery grade, purity 91%), 0.51g Fe(NO 3 ) 3 9H 2 O (Tianjin Chemical Reagent Factory, analytically pure, purity 98.5%), 0.51g Ni(NO 3 ) 2 ·6H 2 O (Tianjin Chemical Reagent Factory, analytically pure, purity 98%) and 25.25 g of anhydrous LiNO 3 (Shanghai Zhongli, analytically pure, content 99%), put it in a ball mill tank, the ratio of ball to material is 3:1, the speed is 300 rpm, take it out after ball milling for 3 hours, and then put the powder in the sintering furnace at 1°C Raise the temperature to 350°C / min, keep it for 6 hours, take it out after cooling down to room temperature, and then ball mill it to 325 mesh to obtain active manganese dioxide powder.

[0013] Weigh 85g of nano-sulfur powder (Shanghai Yaotian New Material Technology Co., Ltd.), 10g of active manganese dioxide powder (self-made), 1g of 6mm chopped carbon fiber (Shanghai Lishuo Composite Material ...

Embodiment 2

[0017] Preparation of active manganese dioxide: same as Example 1.

[0018] Weigh 90g of nano-sulfur powder (Shanghai Yaotian New Material Technology Co., Ltd.), 5g of active manganese dioxide powder (self-made), 1g of 10mm chopped carbon fiber (Shanghai Lishuo Composite Material Technology Co., Ltd.) and 1g of multi-walled carbon nanotubes (Jiangsu Xianfeng Nano Material Technology Co., Ltd.), put it into a mortar, grind it evenly, pour it into a beaker, and add 97g of absolute ethanol, stir it with a glass rod to form a slurry, and then add 8.33g of 60% mass concentration Polytetrafluoroethylene emulsion, continue to stir to form a paste, use a scraper to spread the paste evenly on a 0.3mm thick hydrophilic carbon fiber cloth (Shanghai Lishuo Composite Material Technology Co., Ltd.), coating load 8mg / cm 2 . Then put it in an oven, heat to 120° C. to dry for 20 minutes under the condition of nitrogen protection, cool down, take it out, and obtain a sulfur electrode. On the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com