Method for strengthening Cr(VI) electroreduction by virtue of small molecular inorganic acid

A small molecule organic acid and inorganic acid technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as low efficiency and limit the feasibility of industrial application, and achieve electric energy Low consumption, easy to promote and use on a large scale, and the effect of adding less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

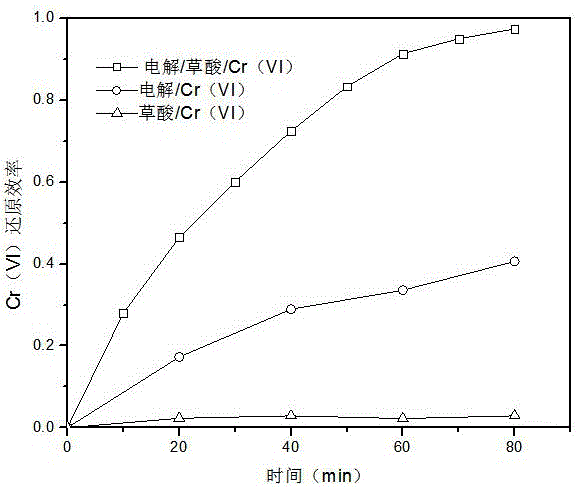

Embodiment 1

[0022] Add 0.5mM oxalic acid to the water body with a Cr(VI) concentration of 0.1mM (mmol / L, the same below), adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL, and use a low-voltage DC power supply to conduct electrolysis with a constant current I=20mA. The anode used is flake graphite, iron or platinum (1cm×1cm), and the cathode is a sheet Activated carbon fiber, glassy carbon, metal platinum or graphite (3cm×3cm), during this process, use a magnetic stirrer to stir the electrolyte to mix evenly.

[0023] Comparative Experiment 1: Add 0.5mM oxalic acid to water with a Cr(VI) concentration of 0.1mM, adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL. Under the condition of no electricity, use a magnetic stirrer to stir the solution to make it uniform....

Embodiment 2

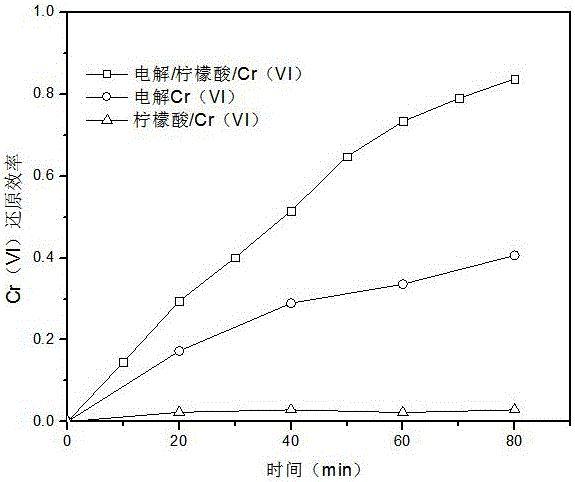

[0026] Add 0.5mM citric acid to water with a Cr(VI) concentration of 0.1mM, adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL, and use a low-voltage DC power supply to conduct electrolysis with a constant current I=20mA. The anode used is flake graphite, iron or platinum (1cm×1cm), and the cathode is a sheet Activated carbon fiber, glassy carbon, metal platinum or graphite (3cm×3cm), during this process, use a magnetic stirrer to stir the electrolyte to mix evenly.

[0027] Comparative Experiment 1: Add 0.5mM citric acid to water with a Cr(VI) concentration of 0.1mM, adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL. Under the condition of no electricity, use a magnetic stirrer to stir the solution to make it uniform.

[0028] Comparative experiment ...

Embodiment 3

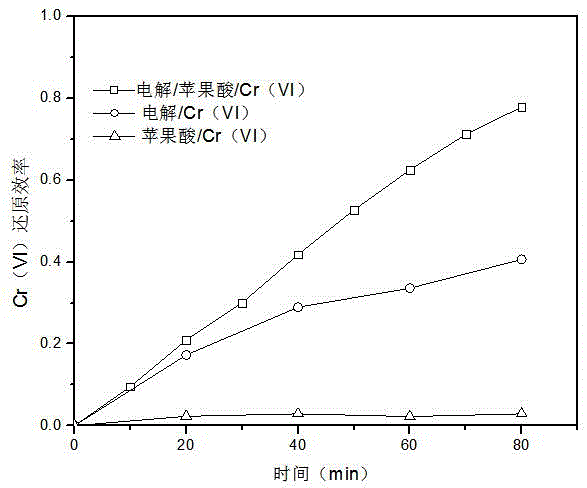

[0030] Add 1 mM malic acid to the water body with Cr(VI) concentration of 0.1 mM, adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL, and use a low-voltage DC power supply to conduct electrolysis with a constant current I=20mA. The anode used is flake graphite, iron or platinum (1cm×1cm), and the cathode is a sheet Activated carbon fiber, glassy carbon, metal platinum or graphite (3cm×3cm), during this process, use a magnetic stirrer to stir the electrolyte to mix evenly.

[0031] Comparative experiment 1: Add 1 mM malic acid to water with a Cr(VI) concentration of 0.1 mM, adjust the pH value to 3 with sulfuric acid, and use Na 2 SO 4 Adjust the conductivity of the electrolyte to about 3ms / cm, so that the mixed solution reaches 200mL. Under the condition of no electricity, use a magnetic stirrer to stir the solution to make it uniform.

[0032]Comparative experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com