Preparation method of perovskite nanocrystals

A perovskite and nanocrystal technology, applied in the field of materials, can solve problems such as harsh and cumbersome synthesis conditions, increase limitations, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

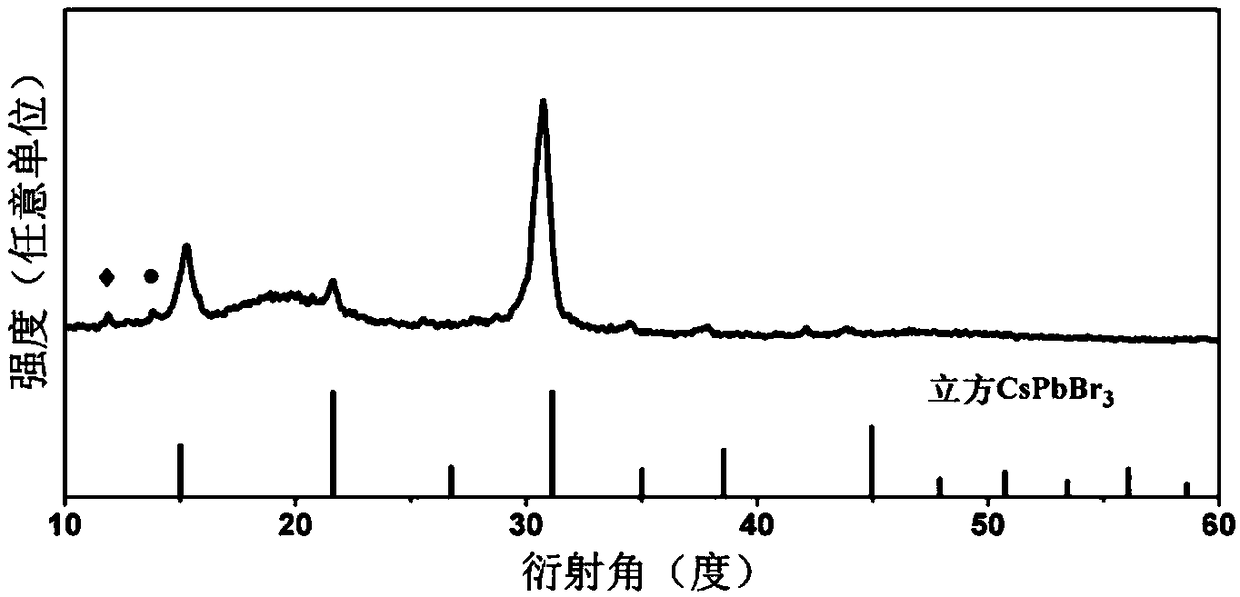

[0120] Example 1 Sample 1 # preparation of

[0121] Step 1: Add 10ml of octadecene to a 20ml reagent bottle, add 0.5ml of oleic acid and 0.5ml of oleylamine, then add 1ml of isopropyl titanate, and keep stirring (shake the table at a frequency of 560 per minute Oscillation, the shaker model is KS130basic);

[0122] Step 2: Weigh 0.3mmol of PbBr 2 and 0.1 mmol of Cs 2 CO 3 Add it to the above-mentioned constantly stirring solution, at room temperature and air environment, it can be observed that the color of the solution turns yellow after a few minutes, and a bright green light can be observed under the irradiation of ultraviolet lamp (365nm) after continuous stirring for 60 minutes;

[0123] Step 3: Centrifuge the reacted solution at 11,000rpm for 5 minutes to retain the CsPbBr in the lower precipitate 3 nanocrystals and preserved in toluene, the obtained CsPbBr 3 Nanocrystal is recorded as 1 # .

Embodiment 2

[0124] Example 2 Sample 2 # preparation of

[0125] Other steps are the same as in Example 1, except that the isopropyl titanate in step 1 is changed to tetraethyl titanate, and the obtained CsPbBr 3 Nanocrystal is recorded as 2 # .

Embodiment 3

[0126] Example 3 Sample 3 # preparation of

[0127] Other steps are the same as in Example 1, except that the isopropyl titanate in step 1 is changed to n-tetrabutyl titanate, and the obtained CsPbBr 3 Nanocrystalline is recorded as 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com