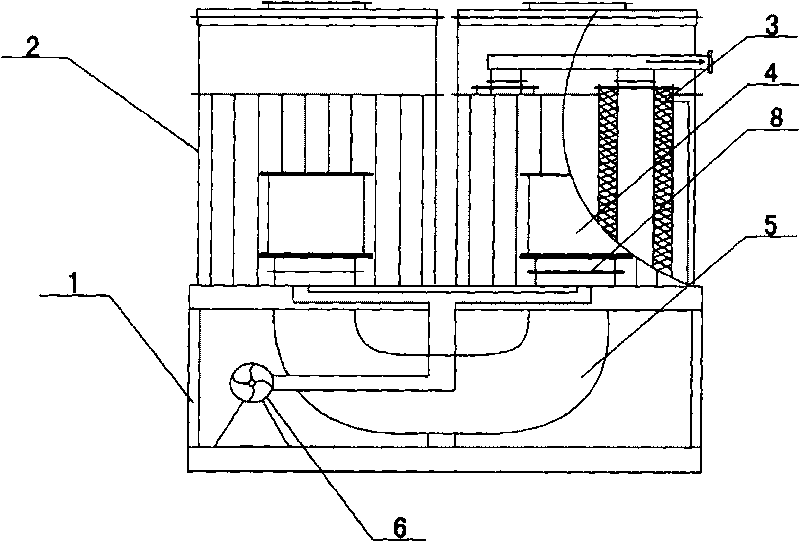

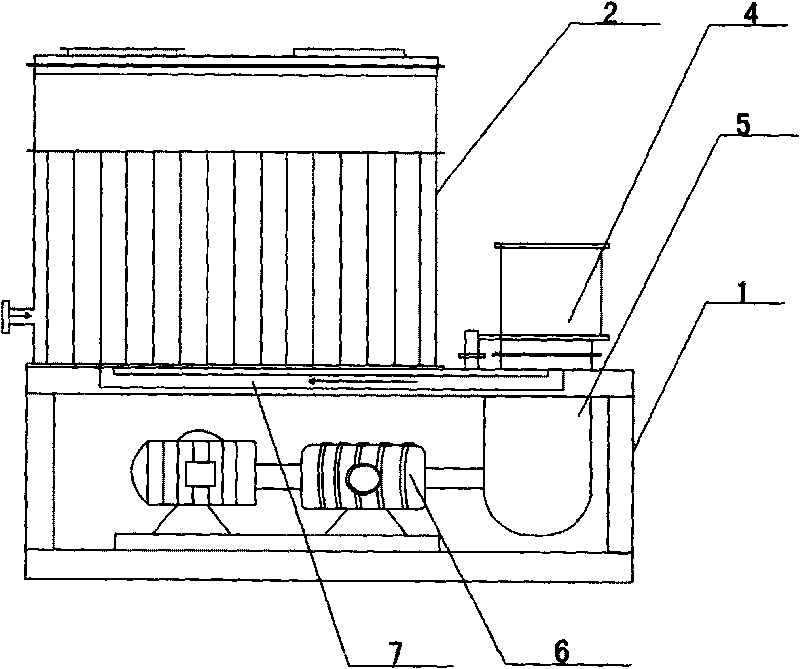

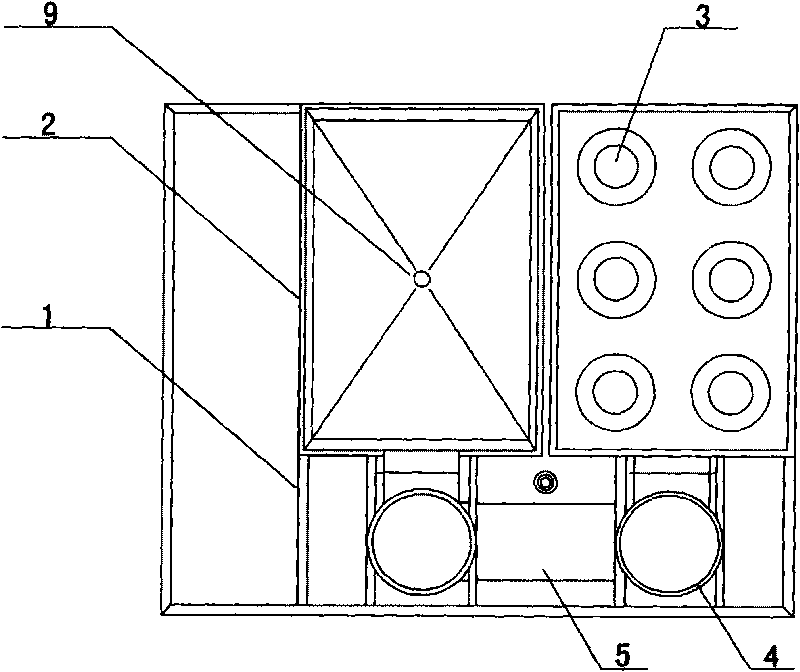

Iron-carbon fiber micro-electrolysis reaction device

A reaction device and micro-electrolysis technology, applied in the direction of reducing water/sewage treatment, etc., can solve the problems of strong adsorption and flocculation, large slag production, iron filings agglomeration, etc., and achieve the effect of small pore size, speeding up the reaction speed, and increasing the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Our company's test 1, will enter the water COD cr The content is 670mg / L, the PH value of the influent water is 12, and the COD is filtered for 0.5 hours cr Begin to decline, the pH value is 9, and it can be reduced to 210mg / L after filtration, COD cr The removal rate was 68%.

Embodiment example 2

[0021] Our company's test 2, will enter the water COD cr The content is 350mg / L, the PH value of the influent water is 12.5, and the COD is filtered for 0.5 hours cr It began to decline, the pH value was 9, and it could be reduced to 87mg / L after filtration, COD cr The removal rate was 75%.

[0022] This device uses the principle of iron-carbon fiber micro-electrolysis to degrade organic matter, and does not need to adjust the acid-base pH value for decomposition. It has the advantages of energy saving and simple structure. It can degrade COD in high-salt wastewater and reclaimed water reuse technology. cr Up to 80 to 90% or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com