Method for separating molybdenum and rhenium from rhenium and molybdenum-containing concentrate

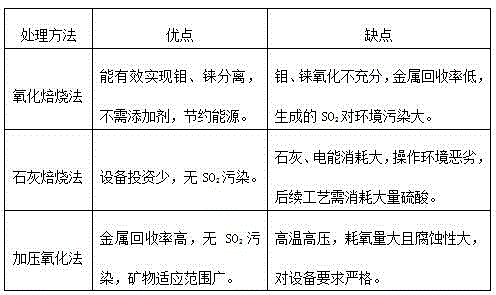

A technology of molybdenum concentrate and concentrate, which is applied in the field of molybdenum metallurgy, can solve the problems that molybdenum concentrate is easily brought into the flue gas, the oxidation rate of rhenium and molybdenum is low, and the oxidation is insufficient, so as to avoid the formation of by-products, Effect of optimizing roasting conditions and improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add a binder and an oxidant to the molybdenum grade 40%, rhenium grade 0.034%, particle size ≤200 mesh rhenium-containing molybdenum concentrate, and then add 3.0% water of the concentrate mass and stir evenly. A disc pelletizer was used to prepare a rhenium-containing molybdenum concentrate pellet 1 with a particle size of 3mm and a moisture content of 12%; the binder was any one of polyvinyl alcohol or polyacrylamide, and its addition The amount is 0.04% of the mass of rhenium-containing molybdenum concentrate; the oxidant is MnO 2 , The addition amount is 3.0% of the mass of rhenium-containing molybdenum concentrate, and the main active ingredient of the rhenium-containing molybdenum concentrate is molybdenite MoS 2 , Rhenium ReS 2 ;

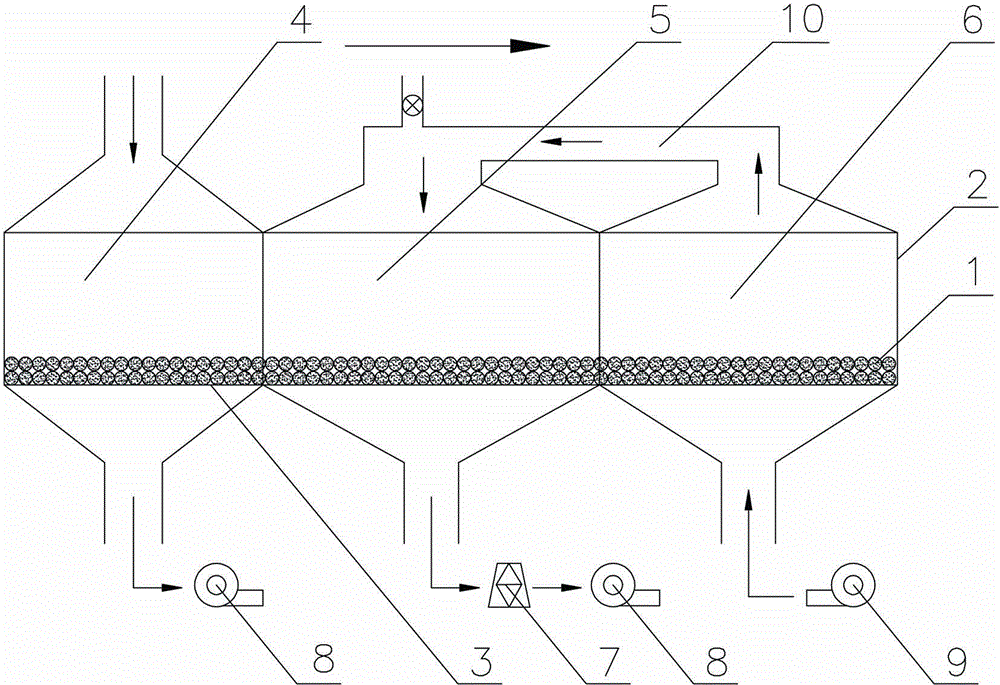

[0032] (2) Spread the rhenium-containing molybdenum concentrate pellets on the grate bed 3 of the grate machine 2 with a thickness of 50mm, and then let the rhenium-containing molybdenum concentrate pellets enter the grate bed into the...

Embodiment 2

[0038] (1) Add binder and oxidant to molybdenum concentrate with molybdenum grade of 30%, rhenium grade of 0.02%, particle size ≤200 mesh, add binder and oxidant, and then add 2.0% water of concentrate mass and stir evenly. A cylindrical granulator is used to prepare pellets of rhenium-containing molybdenum concentrate with a particle size of 4mm and a moisture content of 10%; the binder is either polyvinyl alcohol or polyacrylamide, and the added amount It is 0.06% of the mass of rhenium-containing molybdenum concentrate; the oxidant is MnO 2 , The addition amount is 2.0% of the mass of rhenium-containing molybdenum concentrate;

[0039] (2) Spread the rhenium-containing molybdenum concentrate pellets on the grate bed of the grate machine with a thickness of 60mm, and then make the rhenium-containing molybdenum concentrate pellets enter the preheating chamber of the grate machine along with the grate bed. Drying for 25 minutes at 185°C and a drying wind speed of 1.5m / s, so that ...

Embodiment 3

[0045] (1) Add binder and oxidant to molybdenum grade of 50%, rhenium grade of 0.1%, particle size ≤200 mesh rhenium-containing molybdenum concentrate, and then add 2.5% water of the concentrate mass and stir evenly. A disc pelletizer is used to prepare pellets of rhenium-containing molybdenum concentrate with a particle size of 5mm and a moisture content of 11%; the binder is any one of polyvinyl alcohol or polyacrylamide, and its addition amount It is 0.08% of the mass of rhenium-containing molybdenum concentrate; the oxidant is MnO 2 , The addition amount is 2.5% of the mass of rhenium-containing molybdenum concentrate, and the main active ingredient of the rhenium-containing molybdenum concentrate is molybdenite MoS 2 , Rhenium ReS 2 ;

[0046] (2) Spread the rhenium-containing molybdenum concentrate pellets on the grate bed of the grate machine with a thickness of 80mm, and then make the rhenium-containing molybdenum concentrate pellets enter the preheating chamber of the gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com