Flue gas desulphurization method and apparatus

A flue gas and desulfurization tower technology, applied in the field of flue gas desulfurization and production of sulfuric acid, can solve the problems of difficult separation, high operating costs, ozone consumption and power consumption, etc., to prevent loss, avoid secondary pollution, increase The effect of gas-liquid mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

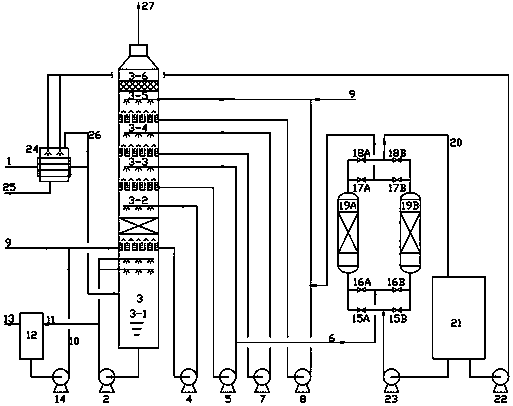

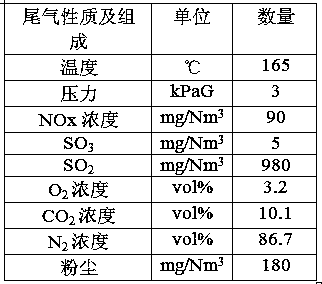

[0036] The flue gas composition of a catalytic cracking catalyst regenerated is shown in Table 1.

[0037] Table 1 Composition of flue gas regenerated from a catalytic cracking catalyst

[0038]

[0039] Operating conditions: (1) The dust removal and desulfurization tower adopts two-stage dust removal: the pre-dust removal quenching unit is spraying; the deep dust removal unit is filled with fillers; the operating liquid-gas ratio is 3.0L (absorbent) / m 3 (gas) and 4.0 L (absorbent) / m 3 (gas); (2) The absorption liquid of the desulfurization unit is ferric sulfate solution, in which Fe 3+ The mass concentration is 3.0%, the primary / secondary / tertiary circulation desulfurization adopts the spray method, and the liquid-gas ratio is 3.0 L (absorbent) / m 3 (gas); (3) The pH of the absorption liquid in the liquid holding tank at the bottom of the dust removal and desulfurization tower is 1.0~2.0; (4) There are two absorption liquid regeneration towers, which are equipped with co...

Embodiment 2

[0042] The flue gas composition of adsorbent regeneration in a S zorb unit is shown in Table 2.

[0043] Table 2 Composition of flue gas from adsorbent regeneration in a certain S-zorb device

[0044]

[0045] Operating conditions: (1) The pre-dust removal quenching unit is sprayed; the deep dust removal unit is filled with fillers; the operating liquid-gas ratio is 3.0L (absorbent) / m 3 (gas); (2) The desulfurization unit is 4-stage absorption, and the absorption liquid is ferric sulfate and H 2 o 2 The mixed solution, where Fe 3+ Mass concentration 3.0%, H 2 o 2 The mass concentration is 1.5%, all of which are sprayed, and the liquid-gas ratio is 4.0 L (absorbent) / m 3 (gas); (3) The pH of the absorption liquid in the liquid holding tank at the bottom of the dust removal and desulfurization tower is 1.0 to 2.0; (4) There are two absorption liquid regeneration towers, switching operation, and the commercially available D003 type hydrogen-type strong acid cation exchange...

Embodiment 3

[0048] The flue gas composition of a coal-fired boiler is shown in Table 3.

[0049] Table 3 Flue gas composition of a coal-fired boiler

[0050]

[0051] Operating conditions: (1) The pre-dust removal quenching unit is spraying; the deep dust removal unit is filled with fillers; the operating liquid-gas ratio is 4.0L (absorbent) / m 3 (gas) and 3.0L (absorbent) / m 3 (gas); (2) The desulfurization unit is three-stage absorption, and the absorption liquid is ferric sulfate and H 2 o 2 The mixed solution, where Fe 3+ Mass concentration 3.0%, H 2 o 2 The mass concentration is 0.5%, all adopt the spray method, and the liquid-gas ratio is 3.0 L (absorbent) / m 3 (gas); (3) pH 1.0-2.0 of the absorption liquid in the liquid holding tank at the bottom of the dust removal and desulfurization tower; (4) There are two absorption liquid regeneration towers, switching operation, with commercially available 732# hydrogen-type strong acid styrene-based cation exchange resin inside .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com