Control device for crystal growth furnace cooling water flow adjustment

A technology of crystal growth furnace and cooling water quantity, applied in furnace control device, crystal growth, single crystal growth and other directions, can solve the problems of different thermal energy, difficulty in ensuring stable crystal growth quality, and inability to ensure the symmetry of temperature gradient of crystal growth temperature field, etc. , to achieve the effect of improving stability and repeatability, conducive to industrial production, and strengthening control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, a specific embodiment is listed in conjunction with the accompanying drawings to describe the content and details of the present invention in detail.

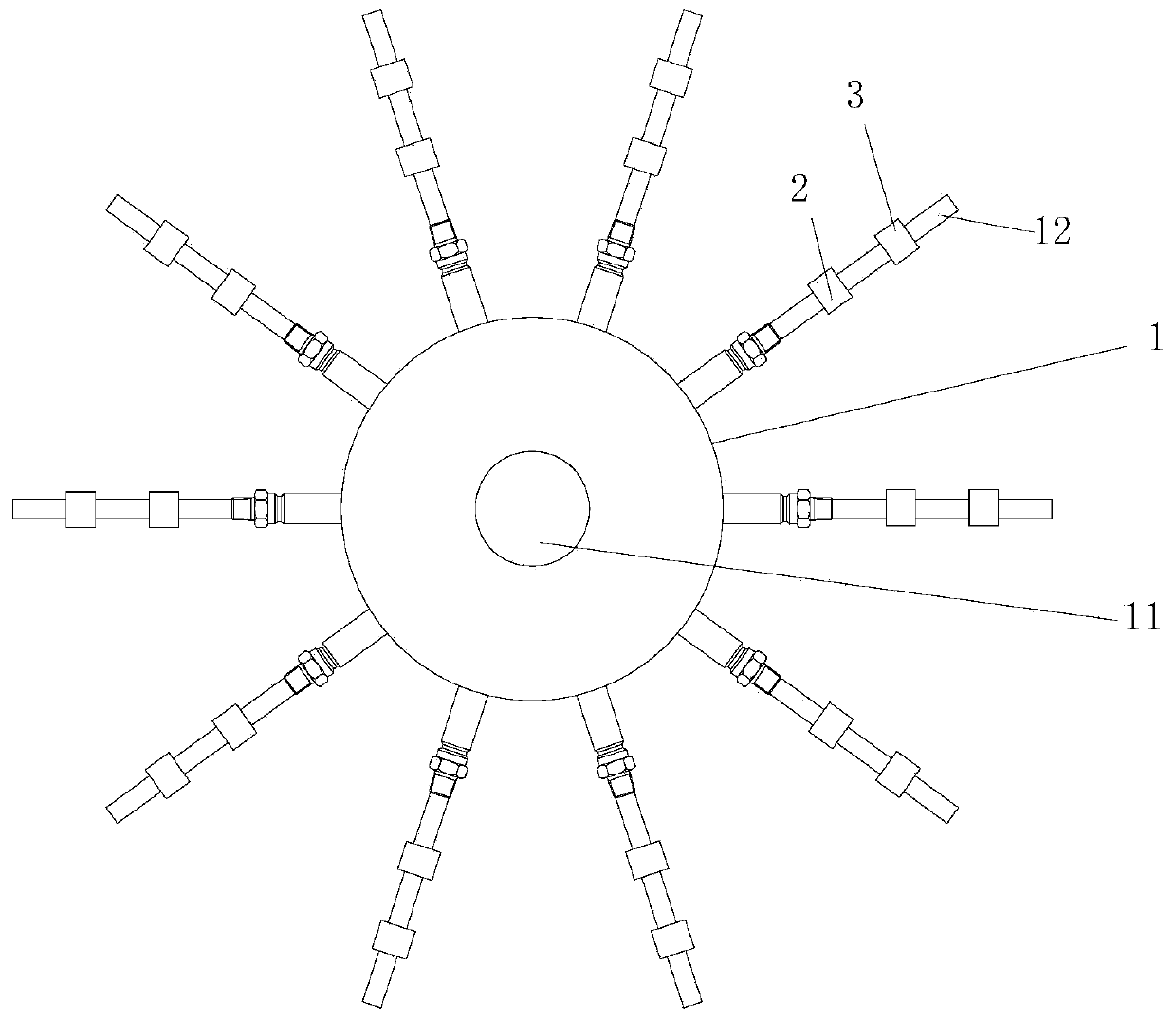

[0017] see figure 1 , a control device for crystal growth furnace cooling adjustment provided by the present invention, comprising a water storage body 1, flow monitoring equipment 2 and flow regulating equipment 3, the flow monitoring equipment 2 selects the electronic flow meter 2, and the flow regulating equipment selects the water flow rate Regulating valve 3. The water storage body 1 selects a stainless steel circular disc body 1, and a water storage cavity is arranged inside the stainless steel circular disc body. The material is 3mm thick. A general water inlet 11 connected to the water storage cavity is provided in the center of the stainless steel circular disc body 1, which is used to connect the furnace water inlet pipe, so that external water can be injected into the water storage cavity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com