Method for preparing sodium metaaluminate solution for synthesis of zeolite with diasporite

A sodium metaaluminate and synthetic zeolite technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of large investment, high equipment and process requirements, and achieve simplified process, reduced production cost, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

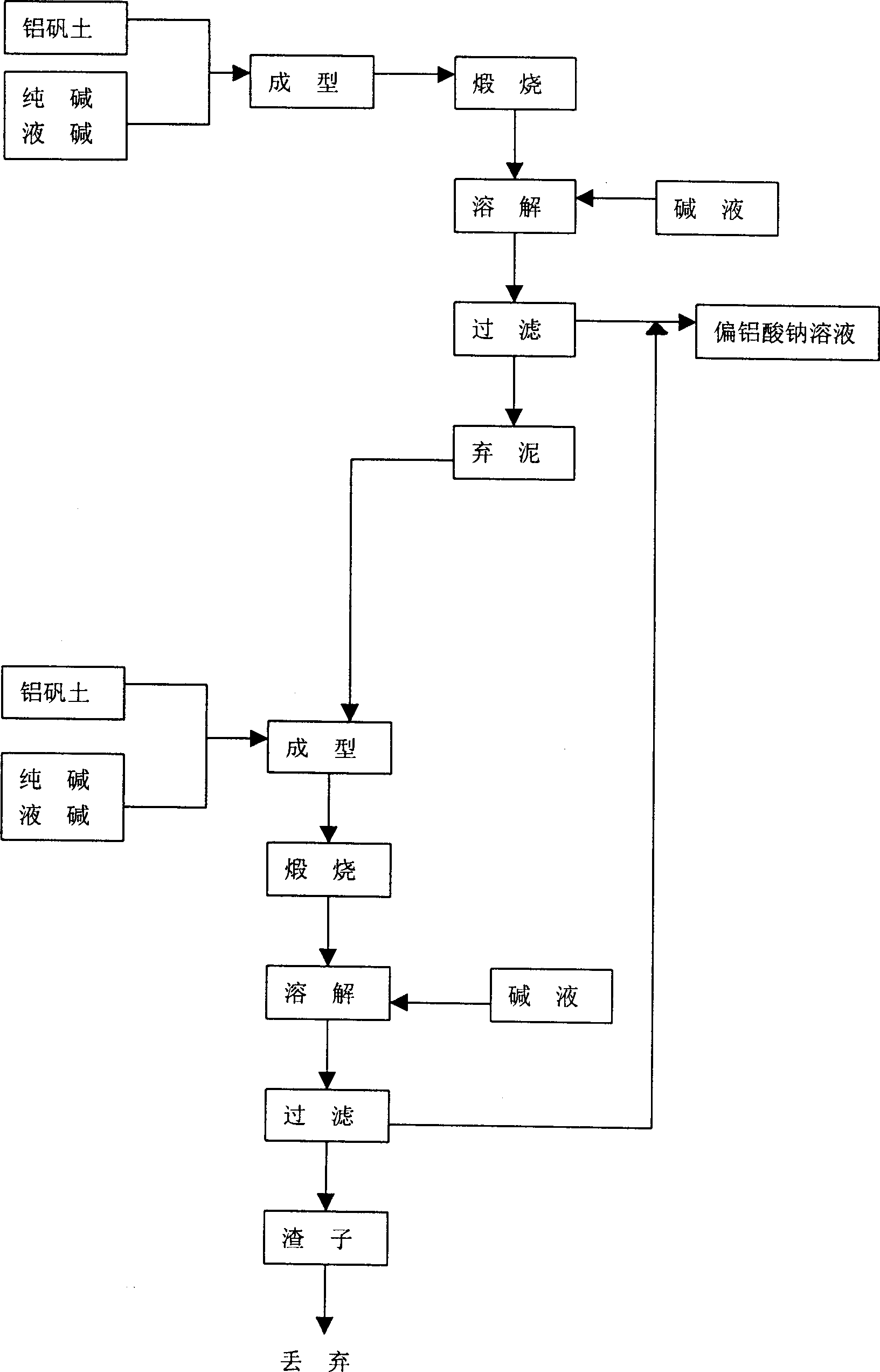

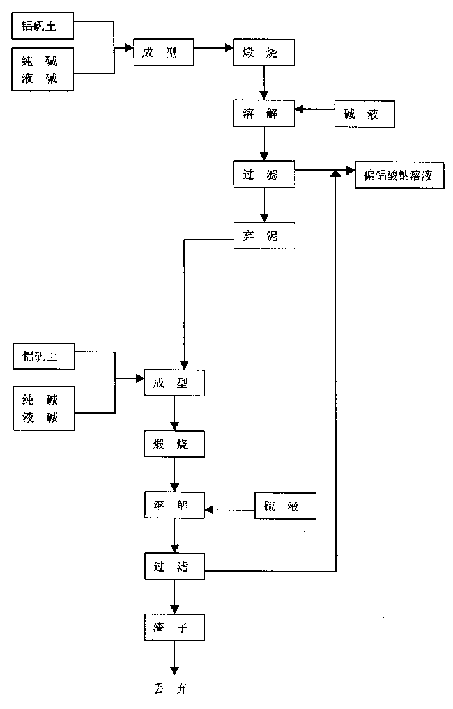

Method used

Image

Examples

Embodiment 6

[0023] Embodiment 6: with 800 kilograms of bauxite of embodiment 1, lye (its composition is NaOH31.28%, Al 2 o 3 1.76%) 880 kg, 400 kg of soda ash (purity 98%), stir evenly in a blender, piled up into bricks, its volume is 24 × 12 × 5.5cm 3 , each brick with a wet weight of about 3.2 metric meters is loaded into a pit car, each pit car can be coded with 8 layers of bricks, and 60 blocks per layer are pushed into the tunnel cellar, calcined to 1080 ° C, kept for 1 hour, taken out and cooled to about 500 ° C, Quickly pour in 4800 kg of lye (its composition is NaOH7.11%, Al 2 o 3 0.41%), stir evenly, at this time the solution is in a boiling state, after keeping for 1 hour, stop stirring, settle statically for 10 minutes, put the mother liquor in the storage tank, then pour it into the filter press, and then press the precipitate into the filter press In, finally get 4800 kilograms of sodium metaaluminate solution, referred to as A (its composition is: Na 2 O11.29%, Al 2 o ...

Embodiment 7

[0026] Embodiment 7: with bauxite 10T in embodiment 1, soda ash (purity 98%) 6T, lye (its composition is NaOH40%, Al 2 o 3 2.1%) 12T is carried out by the operating method of embodiment 6, and the sample after calcining is poured in the lye of 59.6T (its composition is NaOH7.0%, Al 2 o 3 0.41%), dissolved to obtain sodium metaaluminate solution 58.1T (its composition is Na 2 O11.93%, Al 2 o 3 8.72%), residue 12.6T.

[0027] Residue returns calcining again, and its second batching is: bauxite 8T, soda ash (purity 98%) 4T, liquid caustic soda (its composition is NaOH: 40%, Al 2 o 3 : 2.1%) 8T, residue 12.6T, carry out by the operation method of embodiment 6 equally, after calcining, pour in the liquid caustic soda of 60.5T (its composition is NaOH7%, Al 2 o 3 2.1%) is dissolved to obtain sodium metaaluminate solution 59.5T (its composition is Na 2 O11.92%, Al 2 o 3 8.7%) residue was discarded at 12.1T. (its composition is Na 2 O27.53%, Al 2 o 3 25.7%, SiO 2 16.65...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com