Combustor structure for gas stove

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and combustion methods. Effect of improving thermal efficiency and increasing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

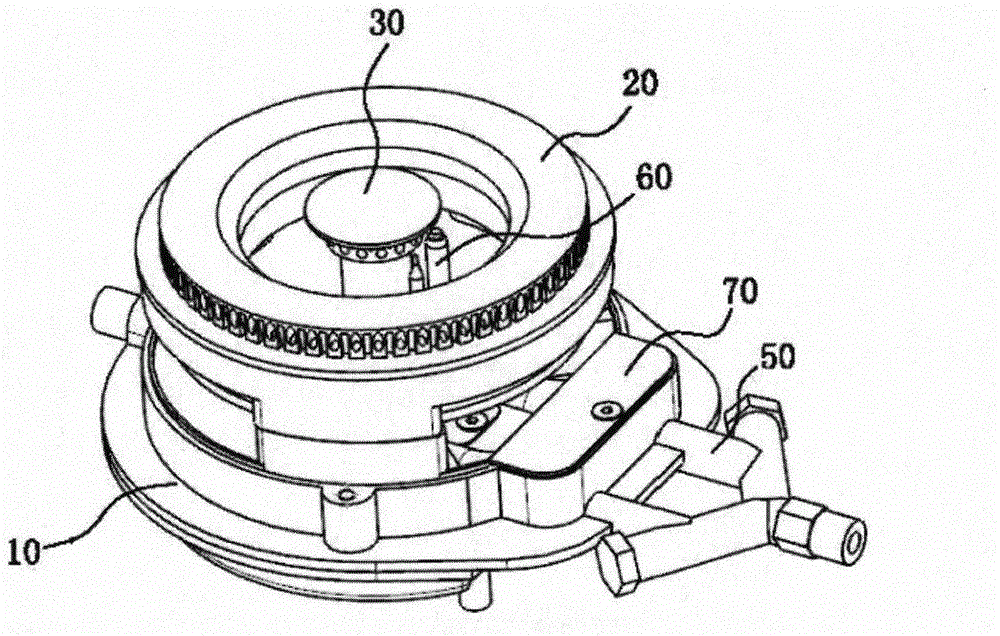

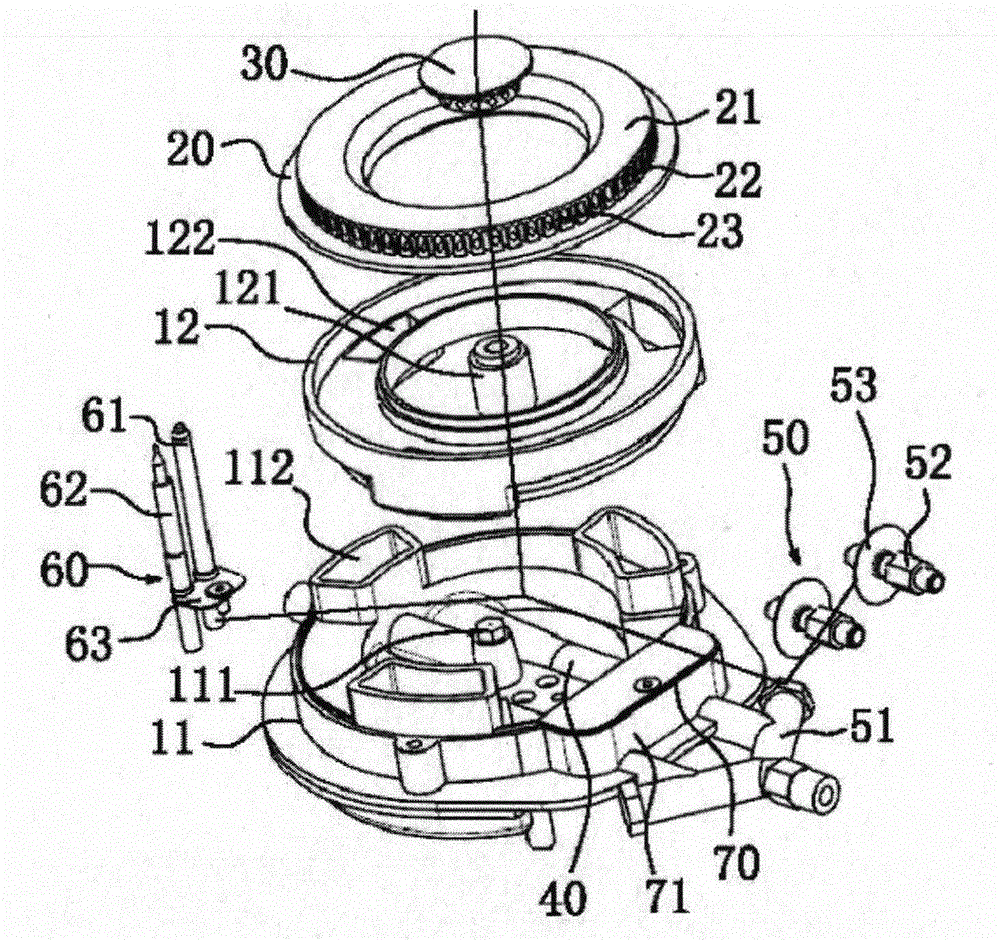

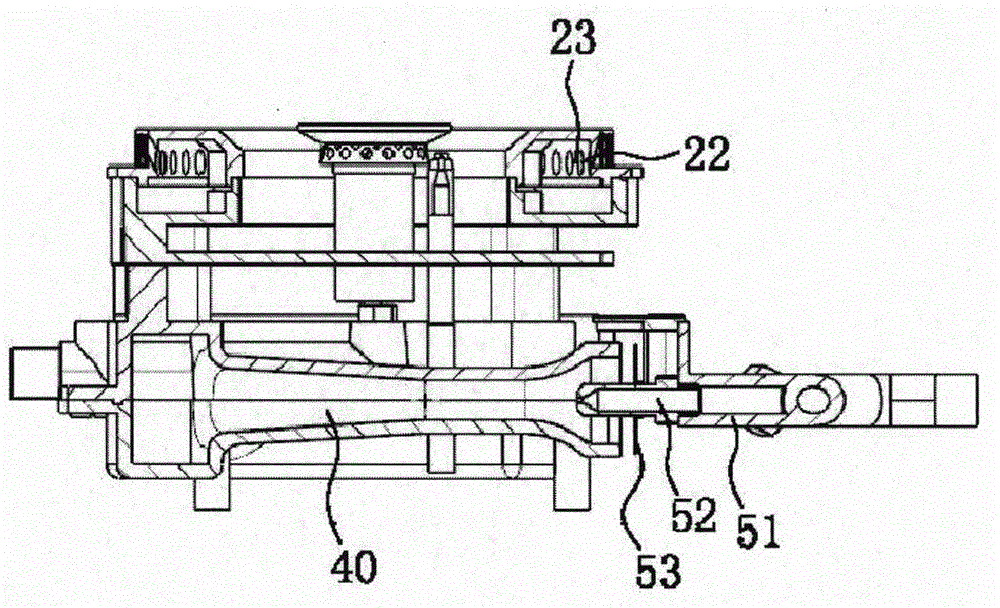

[0026] Such as figure 1 and figure 2 As shown, a burner structure for a gas stove includes a base 10, the base 10 is detachably connected with an outer fire cover 20 and an inner fire cover 30, and the base 10 is provided with at least two Each ejector 40, and the gas outlet of each ejector 40 is located in the base 10 and communicates with the outer fire cover 20 and the inner fire cover 30 through the base 10, so that the gas in each ejector 40 can be Enter into the outer fire cover 20 and the inner fire cover 30 to burn respectively. That is to say, the gas mixed with air once in each injector 40 can enter the outer fire cover 20 and the inner fire cover 30 to burn respectively, which not only increases the heat load, but also makes the combustion of the gas more complete and the thermal efficiency higher .

[0027] The base 10 includes a lower base 11 and an upper base 12 sleeved on the lower base 11. The upper base 12 and the lower base 11 are tightly connected, and t...

Embodiment 2

[0036] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the primary air volume adjustment mechanism 50 includes two straight pipes, and the two straight pipes are respectively connected to the intake end of an ejector 40. The connection with the ejector 40 is provided with a nozzle 52 detachably connected to the straight pipe. The mouth of the nozzle 52 extends to the inside of the ejector 40. The outer wall of the nozzle 52 is screwed with a flap 53, and the flap 53 can move along the The outer wall of the nozzle 52 is rotated so as to adjust the distance between the flap 53 and the air inlet end of the ejector 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com