Dust-containing coal tar negative-pressure gasifying filtering device and using method thereof

A filter device and coal tar technology, applied in chemical instruments and methods, separation methods, tar processing, etc., can solve the problems of poor sediment fluidity, easy to block outlets, easy to block tower internals, etc., to achieve simple and convenient use, improve Yield, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

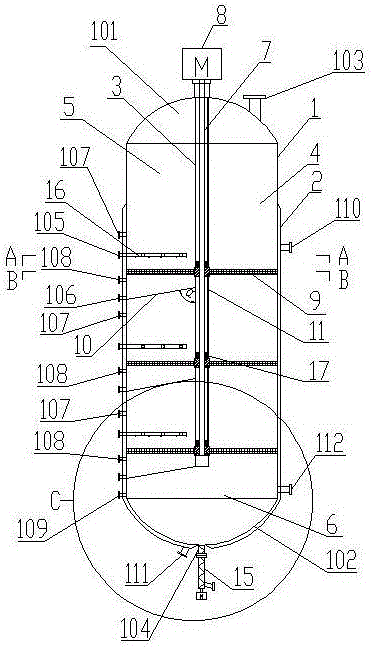

[0024] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

[0025] figure 1 It is a structural schematic diagram of a dusty coal tar negative pressure gasification filter device of the present invention. A dusty coal tar negative pressure gasification filter device, including a separator cylinder 1, the separator cylinder 1 includes a hollow cylinder with an upper head 101 and a lower head 102, and the end of the upper head 101 is provided with a gas phase The outlet 103 and the residue discharge port 104 are set on the lower head 102, the residue discharge port 104 end is connected with the discharge screw 15, and the outlet end of the discharge screw 15 can be connected with the slag tanker to directly input the residue into the slag tanker .

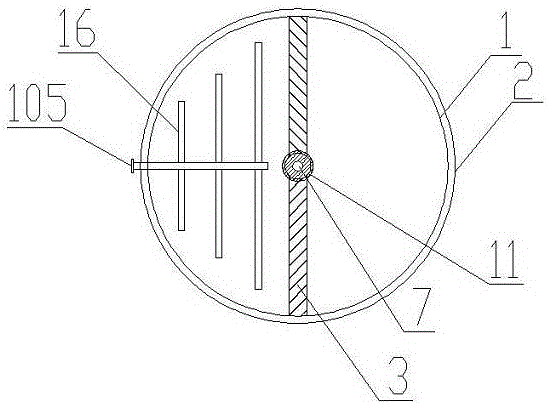

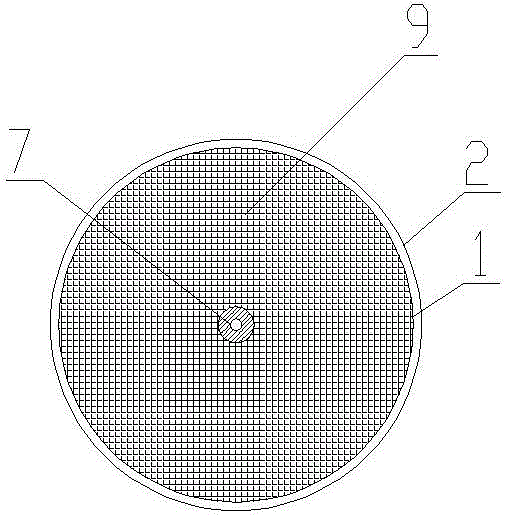

[0026] Such as figure 1 , 4 shown (where, Figure 4 Mainly to show the internal space structure of the separator cylinder 1, so all the openings on the separator cylinder 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com