Research on dechloridation process of lead chloride slag

A lead chloride and dechlorination technology is applied in the research field of lead chloride slag dechlorination process, which can solve the problems of furnace and steel smoke pipe corrosion, chlorine gas pollution of the atmosphere, and reduce the direct yield of smelting, etc., to achieve dechlorination High efficiency, increased direct yield, quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions provided by the above are explained in detail below in conjunction with the examples, but they are not intended to limit the protection scope of the claims of the present invention.

[0020] In the following examples, the lead chloride slag of Guizhou Smelter is used for dechlorination, and its main components are as follows:

[0021] Pb: 70.11%; Cu: 1.63%; Bi: 0.14%; Sb: 0.33%; As: 0.19%; - : 25.62%; Ag: 491g / t.

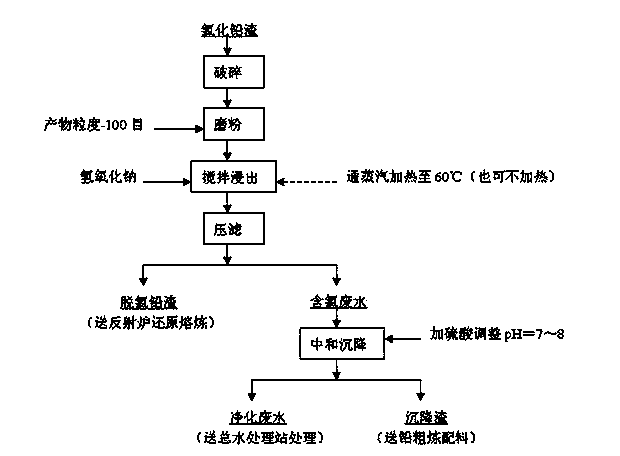

[0022] as attached figure 1 Shown, after this lead chloride slag is ground, send into reactor and carry out dechlorination treatment, the technical index that embodiment obtains is as follows.

[0023] Leaching rate: Cl - : 95.52%; Pb: 1.96%; Cu: 0.22%; Ag: 0.11%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com