Process and apparatus for separating gas and liquid

A gas-liquid separation device, gas-liquid separation technology, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low separation load, large volume, poor separation effect, etc., and achieve improved separation efficiency , Increase separation efficiency, reduce the effect of droplets being taken away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

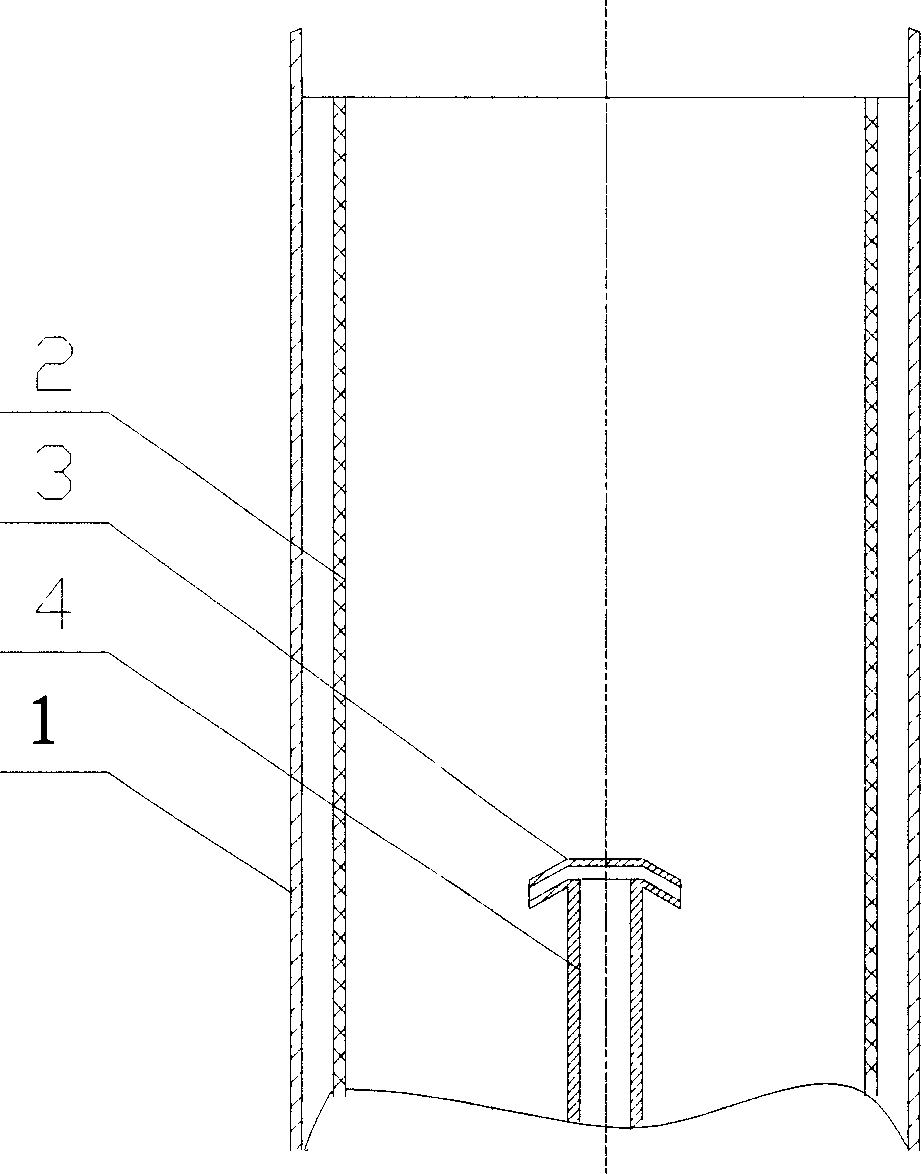

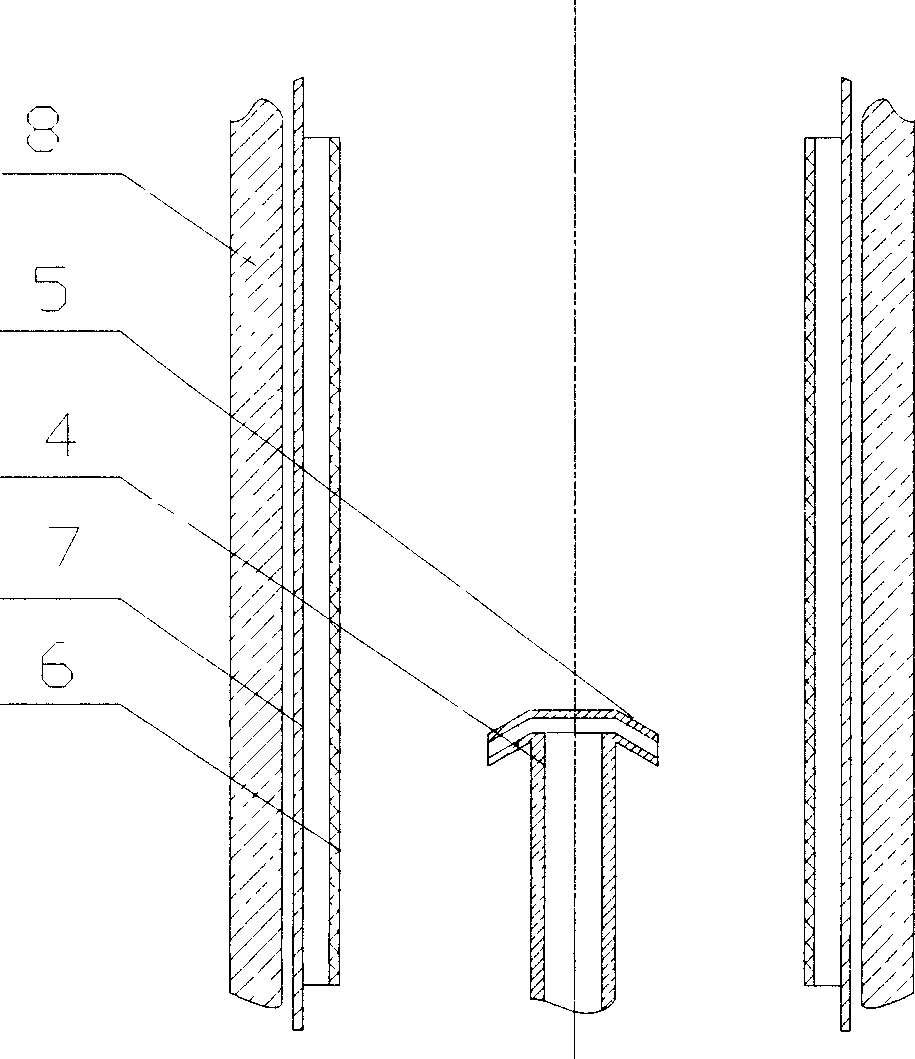

[0016] The separation method that the present invention adopts is a kind of centrifugal separation device (as figure 1 and 2 Shown), the liquid inertial separation generator is a centrifugal force separation device, and other parts of the centrifugal force separation device are the same as the prior art, so no longer describe it here, and its characteristics are on the internal structure of the centrifugal force separation device. As can be seen from the accompanying drawings, between the inner cylinder 7 of the centrifugal force separation device and the centrifugal separation generator 5 (belonging to a known conventional technology), at least one layer of stainless steel wire mesh 6 is set, under the centrifugal separation generator 5 A feed pipe 4 is connected. The separated liquid enters the centrifuge generator 5 through the feed pipe 4, and then falls out of the centrifuge generator 5, and then falls on the inner wall of the steel inner tube 7 through the stainless ste...

Embodiment 2

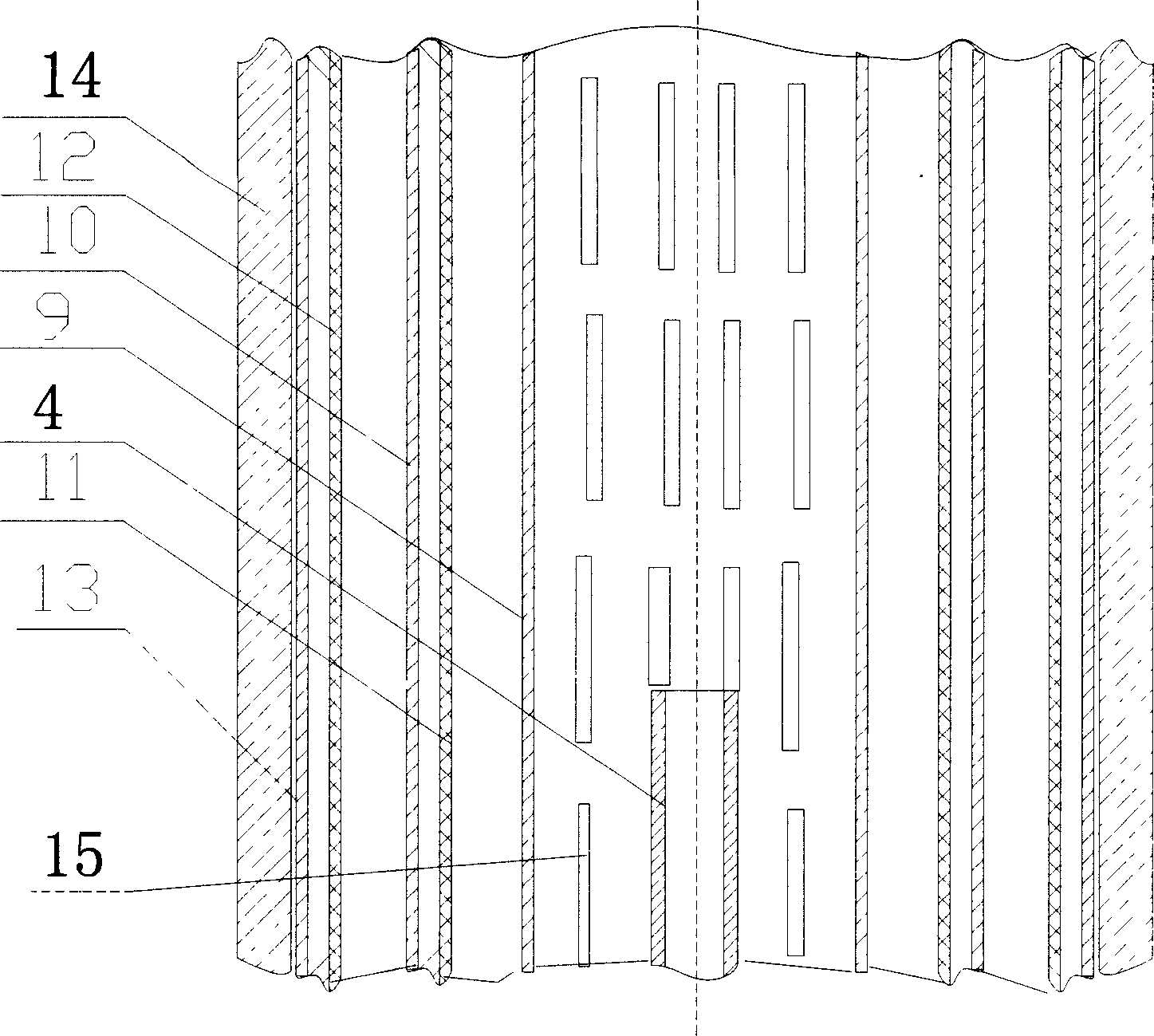

[0018] image 3 As another embodiment of the present invention, as can be seen from the accompanying drawings, the present invention is a multiple baffle separation device, the liquid inertia separation generator is a baffle separation device, and the general structure of the baffle separation device is the same as that of the known The conventional baffle separation device is the same, and it is characterized in that the liquid sprayed out after each baffle will be processed by a flexible layer of wire mesh. From attached image 3 It can be seen that at least one layer of nylon mesh 11 and 12 is provided between the inner cylinder 13 of the baffle separation device and the baffle 10 and between the baffle 10 and the baffle 9. 9 is connected with feed pipe 4. The separated liquid enters the baffle plate 9 through the feed pipe 4, and is sprayed out from the baffle plate hole 15 on the baffle plate 9, first passes through the nylon screen 11 and then falls onto the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com