Method for preparing high-purity hesperidin

A high-purity technology for hesperidin, which is applied in the field of preparation of high-purity hesperidin, can solve the problems of low purity of hesperidin, large environmental pollution, and low energy consumption, and achieve good impurity removal effect and low energy consumption , The effect of improving the total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 A preparation method of hesperidin

[0020] A preparation method for hesperidin, comprising the steps of:

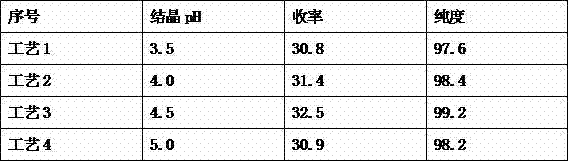

[0021] 1) Impurity removal: Grind 100g of Citrus aurantium raw material, add 500mL of 40% n-butanol aqueous solution, use dilute hydrochloric acid to adjust the pH of the solution to 3.5 and heat the solution to 50°C, soak for 50 minutes and then filter;

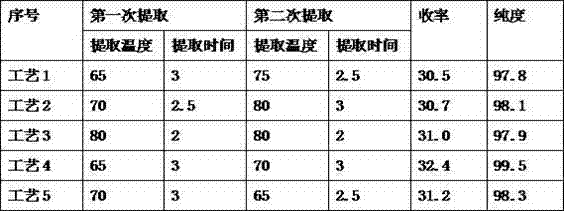

[0022] 2) Gradient extraction: Add 500mL of sodium hydroxide-ethanol-water solution to the filtered filter residue to carry out the first step of extraction, wherein the mass fraction of sodium hydroxide in the sodium hydroxide-ethanol-water solution is 5%, ethanol The volume fraction is 70%, heating and maintaining the extraction temperature at 70°C, extracting and soaking for 3 hours and then filtering to obtain the filtrate; add 300mL of sodium hydroxide-ethanol-water solution to the filtered filter residue for the second step of extraction, in which the hydroxide The mass fraction of sodium hydrox...

Embodiment 2

[0024] Example 2 A preparation method of hesperidin

[0025] A preparation method for hesperidin, comprising the steps of:

[0026] 1) Impurity removal: crush 100g of citrus aurantium raw material, add 500mL of 40% n-butanol aqueous solution, use dilute hydrochloric acid to adjust the pH of the solution to 4 and heat the solution to 40°C, soak for 40 minutes and then filter;

[0027] 2) Gradient extraction: Add 500mL of sodium hydroxide-ethanol-water solution to the filtered filter residue to carry out the first step of extraction, wherein the mass fraction of sodium hydroxide in the sodium hydroxide-ethanol-water solution is 5%, ethanol The volume fraction is 70%, heating and maintaining the extraction temperature at 69°C, extracting and soaking for 2 hours and then filtering to obtain the filtrate; add 300mL of sodium hydroxide-ethanol-water solution to the filtered filter residue for the second step of extraction, in which the The mass fraction of sodium hydroxide in the s...

Embodiment 3

[0029] Example 3 The preparation method of hesperidin of the present invention

[0030] A preparation method for hesperidin, comprising the steps of:

[0031] 1) Impurity removal: crush 100g of citrus aurantium raw material and add 500mL of 40% n-butanol aqueous solution, use dilute hydrochloric acid to adjust the pH of the solution to 3.5 and heat the solution to 45°C, soak for 60 minutes and then filter;

[0032] 2) Gradient extraction: Add 500mL of sodium hydroxide-ethanol-water solution to the filtered filter residue to carry out the first step of extraction, wherein the mass fraction of sodium hydroxide in the sodium hydroxide-ethanol-water solution is 5%, ethanol The volume fraction is 70%, heating and maintaining the extraction temperature at 74°C, extracting and soaking for 2.25 hours and then filtering to obtain the filtrate; add 300mL of sodium hydroxide-ethanol-water solution to the filtered filter residue for the second step of extraction, in which the The mass fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com