Pulp and peel separator

A technology of separator and peeling, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of manual peeling that cannot meet large-scale production, environmental pollution, sewage treatment troubles, etc., and achieve high peeling efficiency , High separation efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

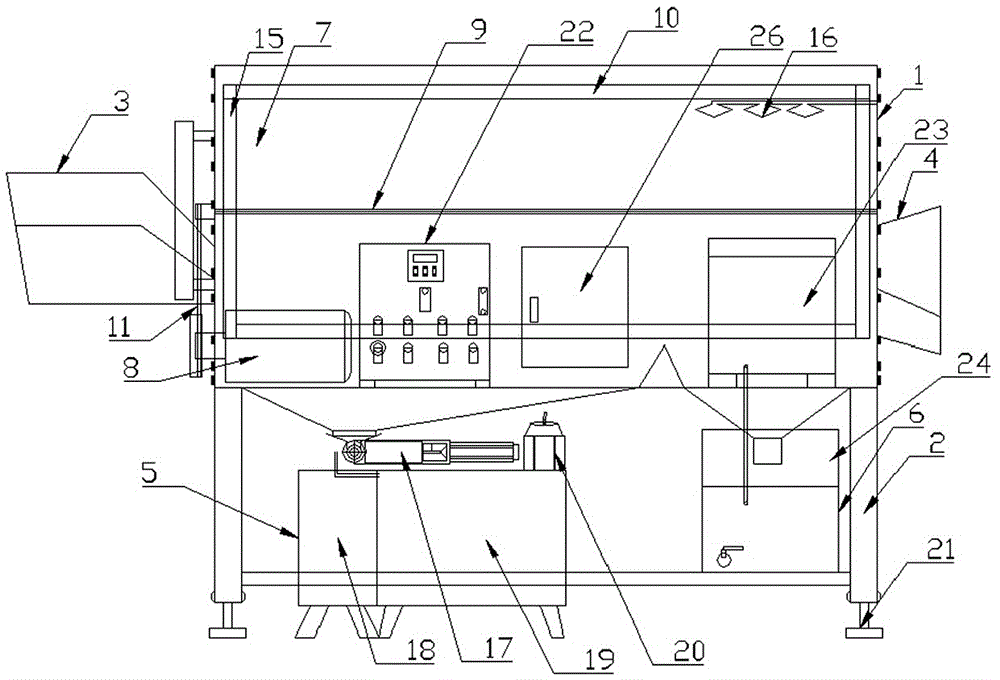

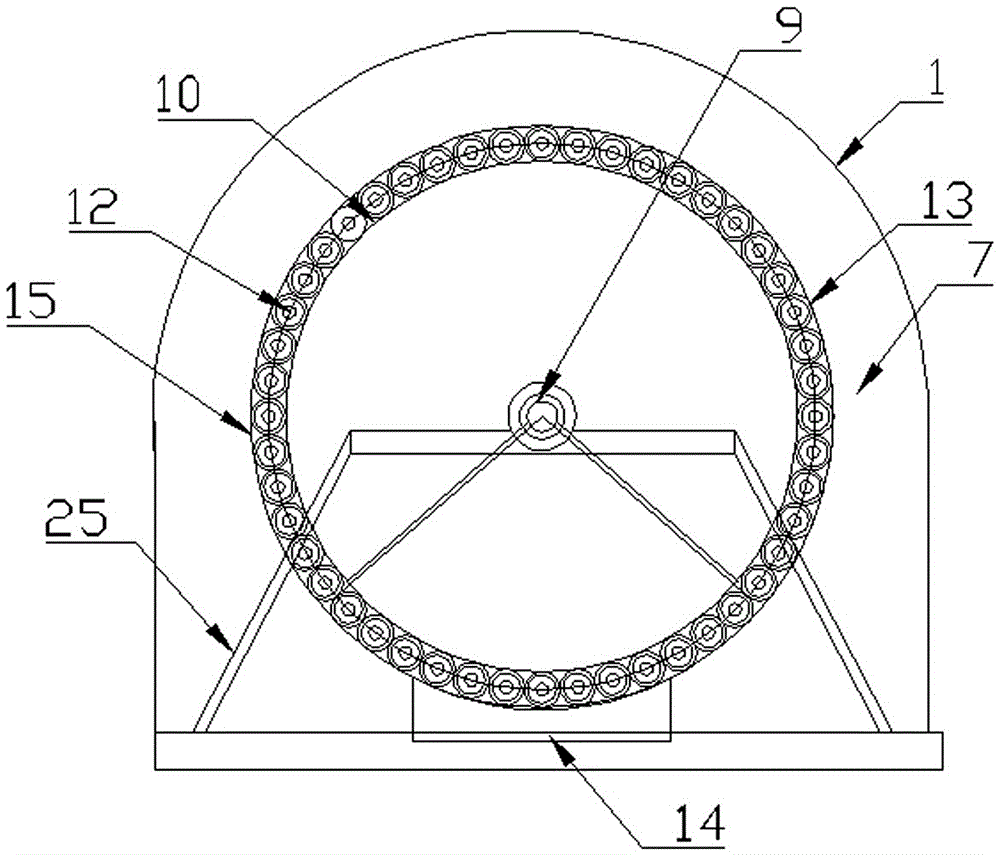

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 , 2 As shown, a pulp and peel separator of the present invention includes a body 1 and supporting legs 2, and is characterized in that: the front and rear ends of the body 1 are respectively provided with a feeding port 3 and a feeding port 4, and the body 1 The front and rear ends of the bottom are respectively provided with a solid-liquid separation device 5 and a waste water treatment device 6, and the inside of the body 1 is provided with a peel and meat separation cylinder 7, and the peel and flesh separation cylinder 7 includes a rotating motor 8, a rotating shaft 9 and a drum 10, The rotating motor 8 is connected with the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com