Zero-discharge online high concentration extraction process for chemimechamical pulp pulping waste liquid

A technology for pulping waste liquid and extraction process, which is applied in the field of pulping and papermaking, and can solve the problems of large water volume and low concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

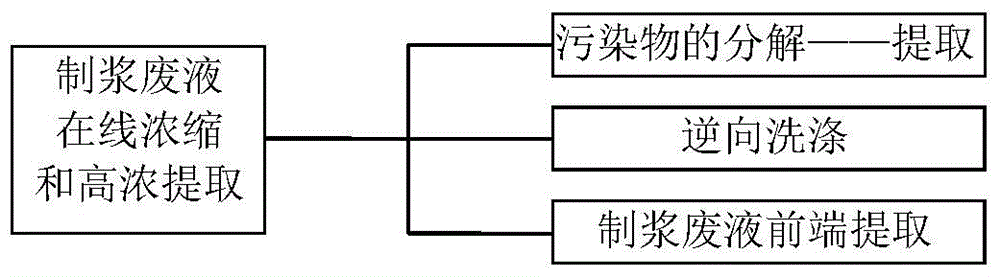

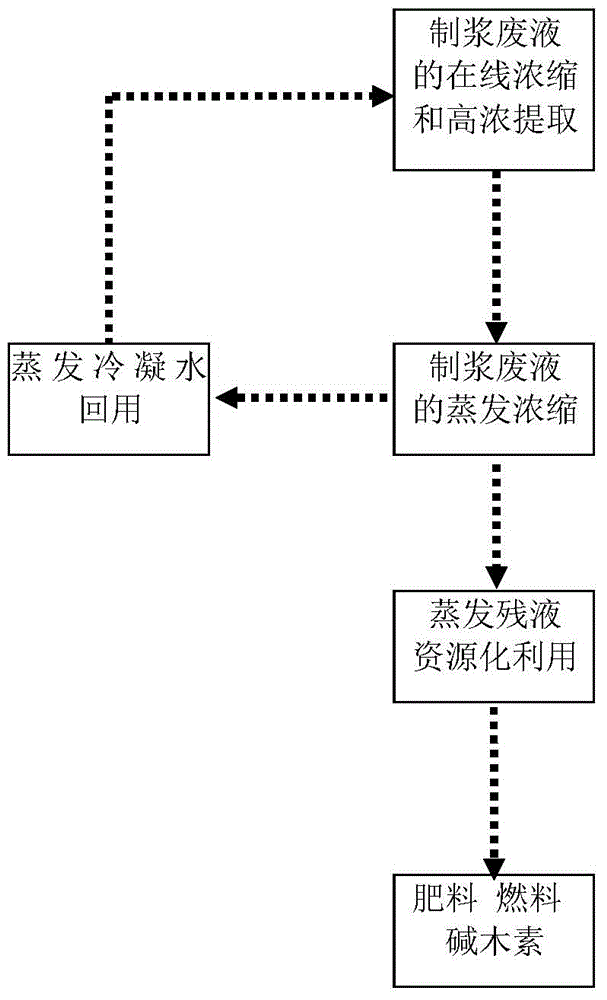

Problems solved by technology

Method used

Image

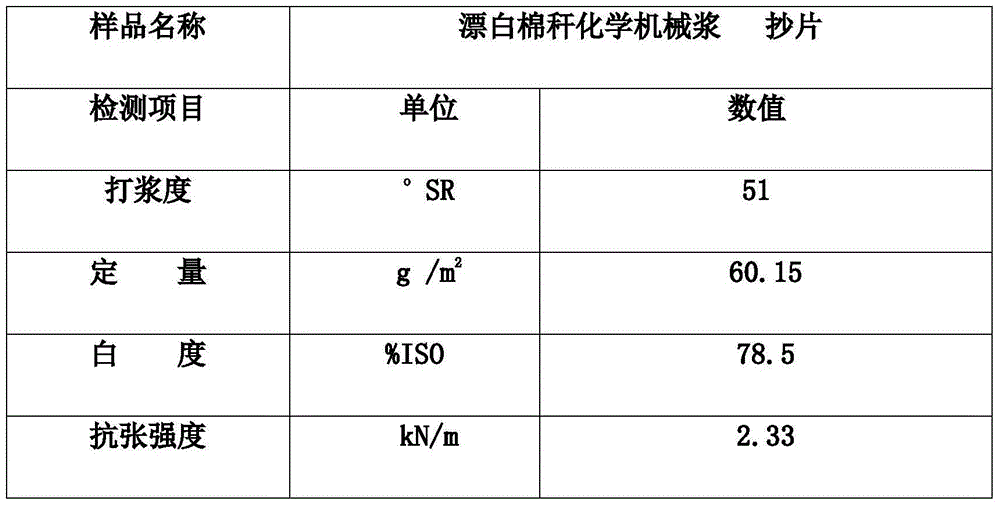

Examples

Embodiment 1

[0061] Raw materials: air-dried wood chips, moisture content 10%, size 10-20mm×20-30mm×30-50mm, place of origin: Liaocheng, Shandong Province

[0062] Implementation steps:

[0063] 1. According to the process flow: wood chip washing (a2) - wood chip cooking (b2) - extrusion tearing (MSD) (c2) - dipping and dosing (d2) - reaction chamber (e2) - extrusion tearing Cracking (MSD) (g2) - impregnation dosing (h2) - reaction chamber (i2) - squeezing and washing (j2) - high consistency refining (k2) - dosing (l2) - reaction chamber (m2)——squeezing and washing (n2)——high consistency refining (o2)——squeezing and washing (p2).

[0064] 2. Chip washing (a2). It is carried out in a drum type washing machine with a specification of Ф1000×1000, the raw material concentration is 5%, and the recycled mixed evaporation condensed water with a COD of 1000mg / L is used to supplement the raw material washing water. The condensed water comes from the seven-effect evaporation station of Shandong T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com