High-efficiency acylation production method of L-methionine nonaqueous solution

A production method and a non-aqueous solution technology are applied in the field of high-efficiency production of L-methionine non-aqueous acylation, which can solve the problems that the traditional process cannot meet the requirements of economic indicators, the yield is low, the sewage discharge is large, and the comprehensive recycling process is reasonable and feasible. , the effect of purifying the environment and promoting ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

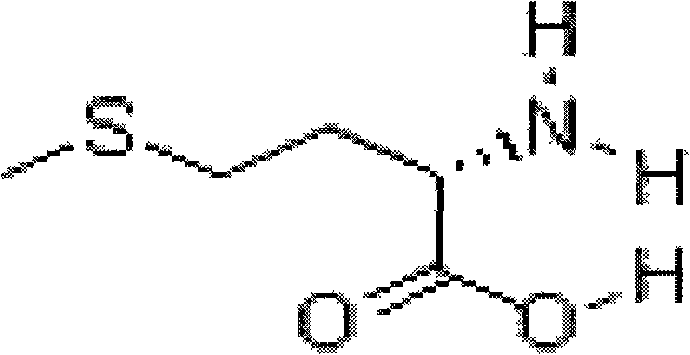

Image

Examples

Embodiment 1

[0028] (1) Dissolve 50kg of DL-methionine in 200kg of acetic acid solution, add 55kg of acetic anhydride dropwise for acylation reaction to generate acylated DL-methionine; the temperature of the acylation reaction is 50°C and the time is 6 hours.

[0029] (2), the acylated DL-methionine solution is recovered by vacuum distillation of acetic acid, after recovering acetic acid, add 1 / 6 volume of water to make unreacted acetic anhydride into acetic acid, continue to recover acetic acid, then add water to extract most of the residual acetic acid to obtain The acylated DL-methionine solution was concentrated, and the content of the acylated DL-methionine was 20% by weight.

[0030] (3) Add 2kg of aminoacylase Aspergillus oryzae (liquid) to the concentrated acylated DL-methionine solution, and carry out the resolution reaction at a constant temperature (36°C). After the resolution reaction is completed, the reaction solution is decolorized and concentrated, and the concentrated solu...

Embodiment 2

[0034] (1) Take 50kg of DL-methionine and dissolve it in 250kg of acetic acid solution, add 60kg of acetic anhydride dropwise for acylation reaction to generate acylated DL-methionine; the temperature of the acylation reaction is 60°C and the time is 5 hours.

[0035] (2), the acylated DL-methionine solution is recovered by vacuum distillation of acetic acid, after recovering acetic acid, add 1 / 5 volume of water to make unreacted acetic anhydride into acetic acid, continue to recover acetic acid, then add water to extract most of the residual acetic acid to obtain The acylated DL-methionine solution was concentrated, and the content of the acylated DL-methionine was 25% by weight.

[0036] (3) Add 2kg of aminoacylase Aspergillus oryzae (liquid) to the concentrated acylated DL-methionine solution, and carry out the resolution reaction at a constant temperature (38°C). After the resolution reaction is completed, the reaction solution is decolorized and concentrated, and the conce...

Embodiment 3

[0040] (1) Dissolve 50kg of DL-methionine in 280kg of acetic acid solution, add 65kg of acetic anhydride dropwise for acylation reaction to generate acylated DL-methionine; the temperature of the acylation reaction is 65°C and the time is 4 hours.

[0041] (2), the acylated DL-methionine solution is recovered by vacuum distillation of acetic acid, after recovery of acetic acid, add 1 / 4 volume of water to make unreacted acetic anhydride into acetic acid, continue to recover acetic acid, then add water to extract most of the residual acetic acid to obtain The acylated DL-methionine solution was concentrated, and the content of the acylated DL-methionine was 30% by weight.

[0042] (3) Add 2kg of aminoacylase Aspergillus oryzae (liquid) to the concentrated acylated DL-methionine solution, and carry out the resolution reaction at a constant temperature (40°C). After the resolution reaction is completed, the reaction solution is decolorized and concentrated, and the concentrated sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com