Prepartion method of plant fertilizer

A production method and plant fertilizer technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve problems such as soil nutrition, pH value, microbial imbalance, increase natural soil fertility, and soil aggregate structure damage, and achieve improvement Crop nutritional conditions, improve detoxification effect, and promote the effect of nutrient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

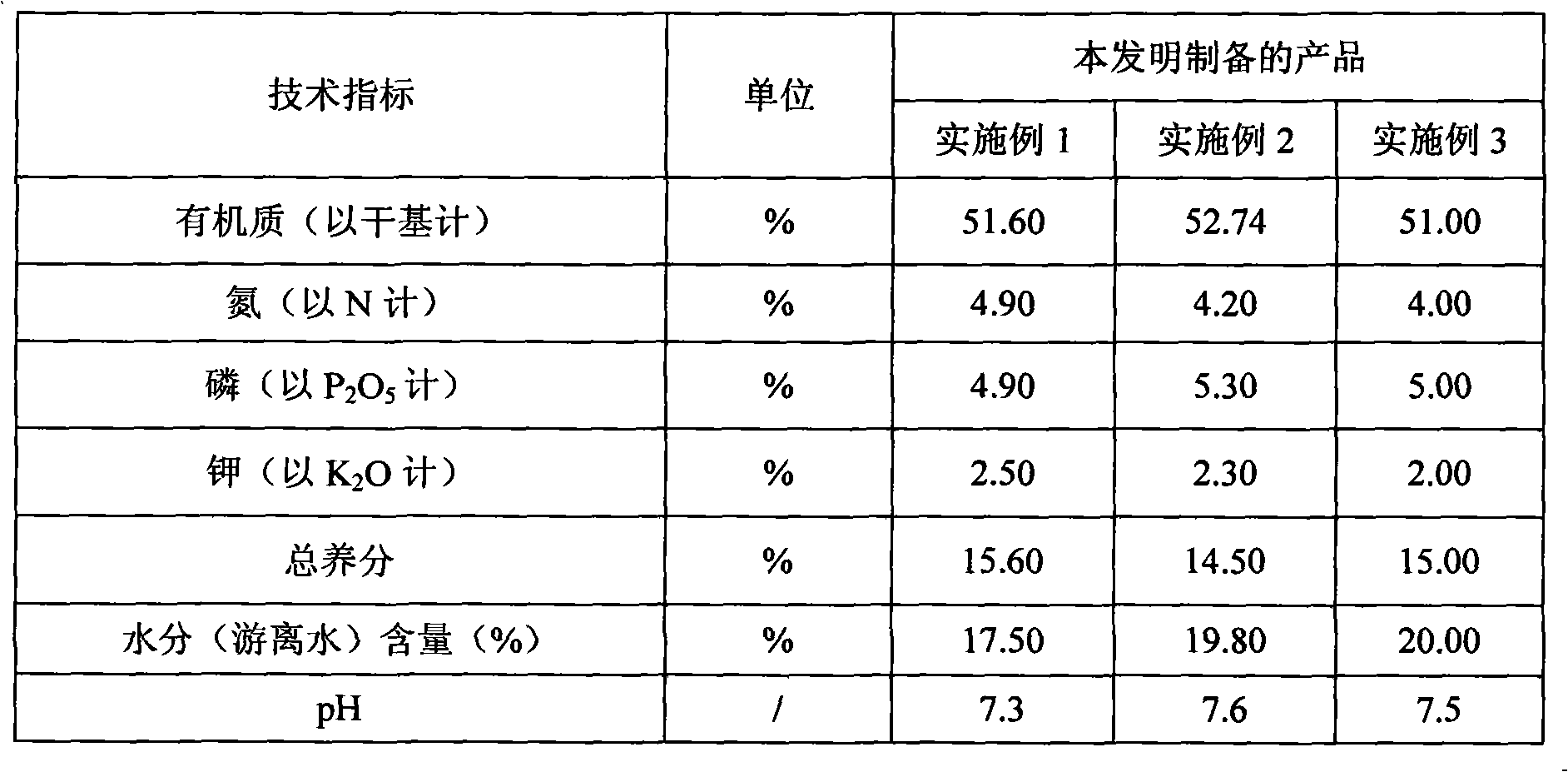

Embodiment 1

[0022] Prepare plant fertilizer as follows:

[0023] (1) according to the ratio of parts by weight, get the following production raw materials ready: 25kg (in terms of dry matter, taking cottonseed husk, bran and corn cob as main raw materials) of discarded bacterium bag after producing Coprinus comatus, 25kg of humus (with dry matter), cotton seeds 25kg, tung seeds 12kg, cow manure 25kg (dry matter), plant ash 8kg;

[0024] (2) Each raw material is pulverized in a pulverizer respectively, so that the pulverized raw material can pass through a 60-mesh screen;

[0025] (3) Stir and mix the raw materials evenly according to the above proportioning ratio, put them into a fermentation tank for fermentation, and ferment naturally for 30 days at 50°C;

[0026] (4) Take out the fermented and decomposed product and dry it so that the free water content of the final product is 15-20%. After drying, carry out secondary pulverization so that the pulverized raw material can pass through ...

Embodiment 2

[0028] (1) According to the ratio of parts by weight, prepare the following raw materials for production: 20kg (in terms of dry matter, taking cottonseed husk, bran and sawdust as main raw materials) of discarded bacterium bags after producing oyster mushrooms, 20kg of humus (in terms of dry matter) Matter basis), cotton seeds 20kg, tung seeds 10kg, cow manure 20kg (calculated as dry matter), plant ash 10kg, rapeseed oil cake 10kg, pine hair 10kg;

[0029] (2) Each raw material is pulverized in a pulverizer respectively, so that the pulverized raw material can pass through an 80-mesh sieve;

[0030] (3) Stir and mix the raw materials evenly according to the above proportioning ratio, put them into a fermenter for fermentation, and ferment naturally for 25 days at 60°C;

[0031] (4) Take out the fermented and decomposed product and dry it so that the free water content of the final product is 15-20%. After drying, carry out secondary crushing so that the crushed raw material ca...

Embodiment 3

[0033] (1) According to the ratio of weight to kg, prepare the following raw materials for production: 15kg of discarded bacterium bags after producing Coprinus comatus (in terms of dry matter, with cottonseed husk, bran and corncobs as main raw materials), 15kg of humus (with dry matter), cotton seeds 15kg, tung seeds 8kg, cow manure or sheep manure 15kg (dry matter), plant ash 12kg, rapeseed oil cake 8kg, pine hair 8kg, charcoal 8kg, peat 8kg;

[0034] (2) Each raw material is pulverized in a pulverizer respectively, so that the pulverized raw material can pass through a 100-mesh screen;

[0035] (3) Stir and mix the raw materials evenly according to the above ratio, put them into the fermentation tank for fermentation, and ferment for 20 days at 70°C, and ventilate and cool down after the fermentation;

[0036] (4) Take out the fermented and decomposed product and dry it so that the free water content of the final product is 15-20%. After drying, carry out secondary crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com