By-pass flow treatment method for circulating water from power plant

A circulating water and flow treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of untimely dosing, insufficient dosage, and non-sustainability and other problems, to achieve the effect of reducing the amount of sewage, increasing the concentration ratio, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

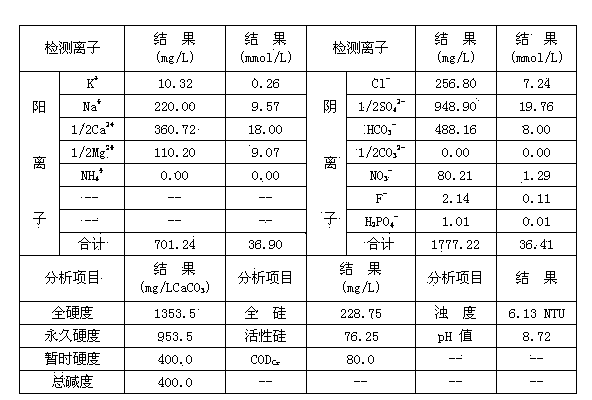

[0017] (1) Draw circulating water from the circulating water tower of the power plant, and use 100m 3 The flow rate per hour is sent to the multi-media filter for filtration. The diameter of the multi-media filter is Φ3200, the layer height is 1200mm, of which the quartz sand is 800mm, anthracite is 400mm, and the output of a single multi-media filter is 50 m 3 / h. The turbidity of the effluent is less than 5NTU. The water quality of circulating water in the power plant is shown in Table 1.

[0018] Table 1 Circulating water quality

[0019]

[0020] (2) Send the effluent from the filter in step (1) to ultrafiltration for treatment. The membrane element of the ultrafiltration is an external pressure ultrafiltration membrane, the recovery rate is 90%, and the SDI of the ultrafiltration effluent is less than 4.0.

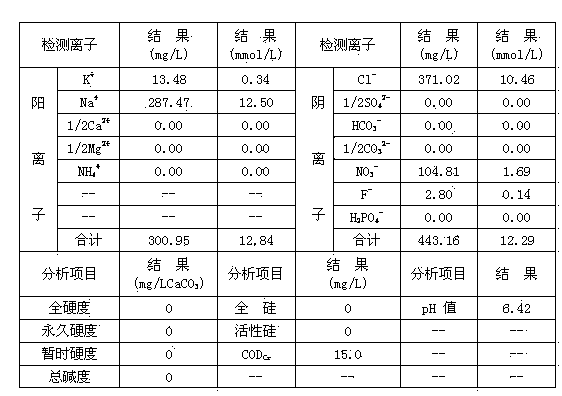

[0021] (3) Add hydrochloric acid to adjust the pH value of the ultrafiltration water obtained in step (2) to 6.0-6.5, and send it to nanofiltration for treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com