Bamboo frame molding process

A molding process, bamboo frame technology, applied in manufacturing tools, wood processing utensils, sugarcane machining and other directions, can solve the problems of inability to fully alleviate and eliminate rebound stress, low work efficiency, inconvenient processing, etc. Service life, effect of reducing the amount of sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

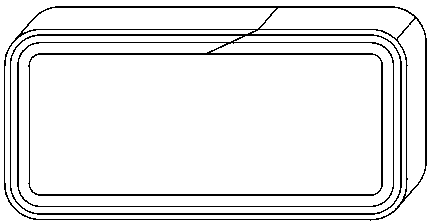

[0028] Bamboo frame molding technique of the present invention is used for making such as figure 1 Shown is a rectangular bamboo frame with rounded corners. Bamboo frame molding equipment is used in the production process, and the production process includes the following steps:

[0029] (1) Production of bamboo strips: According to the dimensions (thickness and perimeter) of the rectangular bamboo frame with rounded corners to be produced, determine the thickness and length of each layer of bamboo strips to make bamboo strips.

[0030] In this embodiment, it is determined to use three layers of bamboo strips, and the thickness of each layer of bamboo strips is not the same. Thin.

[0031] And at the two ends of each layer of bamboo strips, oblique butt ends are respectively processed. One end of the bamboo strips is a chamfer to remove the green surface, and the other end is a chamfer to remove the yellow surface. At the same time, the two sides of the bamboo strips are com...

Embodiment 2

[0044] Bamboo frame molding technique of the present invention is used for making such as figure 1 Shown is a rectangular bamboo frame with rounded corners. Bamboo frame molding equipment is used in the production process, and the production process includes the following steps:

[0045] (1) Production of bamboo strips: According to the dimensions (thickness and perimeter) of the rectangular bamboo frame with rounded corners to be produced, determine the thickness and length of each layer of bamboo strips to make bamboo strips.

[0046] In this embodiment, it is determined to use three layers of bamboo strips, and the thickness of each layer of bamboo strips is not the same. Thin.

[0047] And at the two ends of each layer of bamboo strips, oblique butt ends are respectively processed. One end of the bamboo strips is a chamfer to remove the green surface, and the other end is a chamfer to remove the yellow surface. At the same time, the two sides of the bamboo strips are com...

Embodiment 3

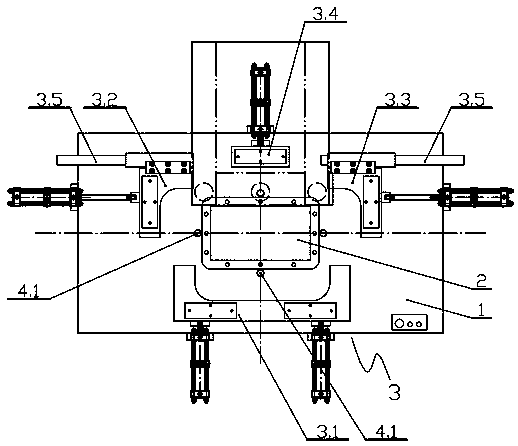

[0060] Such as image 3 , Figure 4 and Figure 5 Shown, above-mentioned embodiment 1 and the used bamboo frame molding equipment of embodiment 2 comprise workbench 1, and workbench 1 is provided with fixed mold 2 and around the movable mold 3 around fixed mold 2, and movable mold 3 can be relatively fixed. The mold 2 moves, and the relative sides of the fixed mold 2 and the movable mold 3 form a bamboo frame molding area, and the movable mold moves relative to the fixed mold to clamp bamboo in the bamboo frame molding area.

[0061] Such as Figure 4 and Figure 5 As shown, the above-mentioned bamboo frame forming equipment also includes a demoulding mechanism 4 and an anti-warping pressing mechanism 5, and the described demoulding mechanism 4 is used to quickly demould the bamboo frame surrounding the fixed mould; The tightening mechanism 5 is used to cooperate with the fixed mold and the movable mold to compress the bamboo to prevent the bamboo from warping when it is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com