Bamboo filament fibre board and bamboo filament, method for making bamboo filament fibre board

A technology of bamboo silk fiber and fiber silk, which is applied in the field of bamboo man-made panels and its production, can solve problems such as unbearable screw connection, unsuitable for decoration and furniture, and poor ability to hold screws repeatedly, so as to increase the added value of products, The effect of rich varieties and strong ability to hold screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

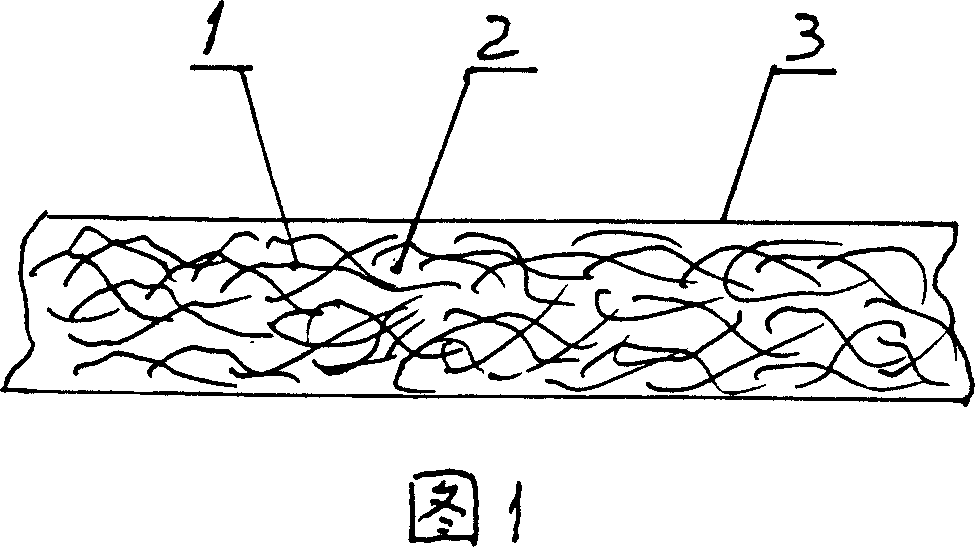

[0025] The present invention is further described as follows with reference to the accompanying drawings in conjunction with specific embodiments: bamboo silk fiberboard 3 is that the diameter that blasting process is made is 0.1mm-0.3mm, and aspect ratio is the bamboo fiber silk 1 of 200:1-500:1 as raw material , a plate made by sizing and hot pressing. The bamboo fiber filaments are bonded by melamine-formaldehyde-urea resin 2. In the bamboo silk fiberboard 3, the bamboo fiber threads 1 intersect each other and are stacked in disorder, see accompanying drawing 1. Due to the characteristics of bamboo silk in the processing unit, the cross-sectional silk structure of bamboo fiberboard has a strong winding ability, which determines that it has a strong screw-holding ability and repeated screw-holding ability; and because of the natural hydrophobicity of bamboo, The expansion rate of bamboo silk is small after absorbing water, and the water expansion of bamboo silk fiberboard i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com