Disc-type wood chip chipper

A planer and wood chip technology, which is applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of large amount of shavings and different cutting directions, so as to achieve less amount of shavings, reduce the amount of shavings, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

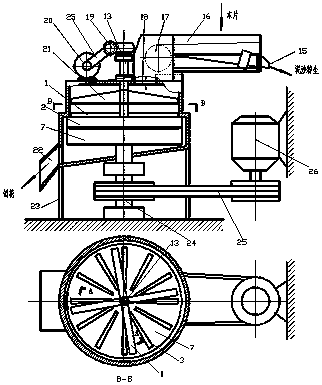

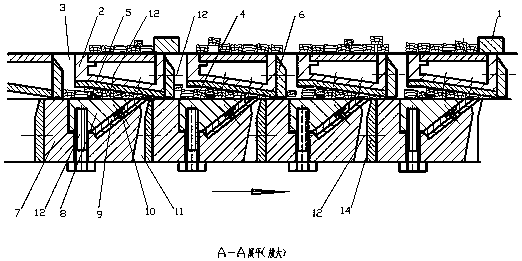

[0019] like figure 1 and figure 2 As shown, a disc-type wood chip planer in the present invention includes a feeding device, a planing device and a discharge port. The cutting device consists of a horizontally arranged discharge rod 1, a feeding tray 2 and a cutter head 7 from top to bottom. The feeding tray 2 is provided with a notch 3, and the cutter head 7 is provided with a flying knife 10, and the wood chips fall to the feeding table. On the material tray 2, under the promotion of the discharge rod 1, the wood chips are pushed into the notch 3 and finally fall on the cutter head 7, and the flying knife 10 moving at high speed slices the wood chips falling on the cutter head 7. The cutterhead 7 rotates rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com