PCB tolerance plate structure and processing method thereof

A board structure and tolerance technology, applied in the directions of printed circuit components, electrical components, printed circuit manufacturing, etc., can solve problems affecting the performance of PCB line units, prone to misalignment of PCB tolerance boards, and failure of PCB tolerance boards. The number of scrapped, cost saving, the effect of ensuring the genuine rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

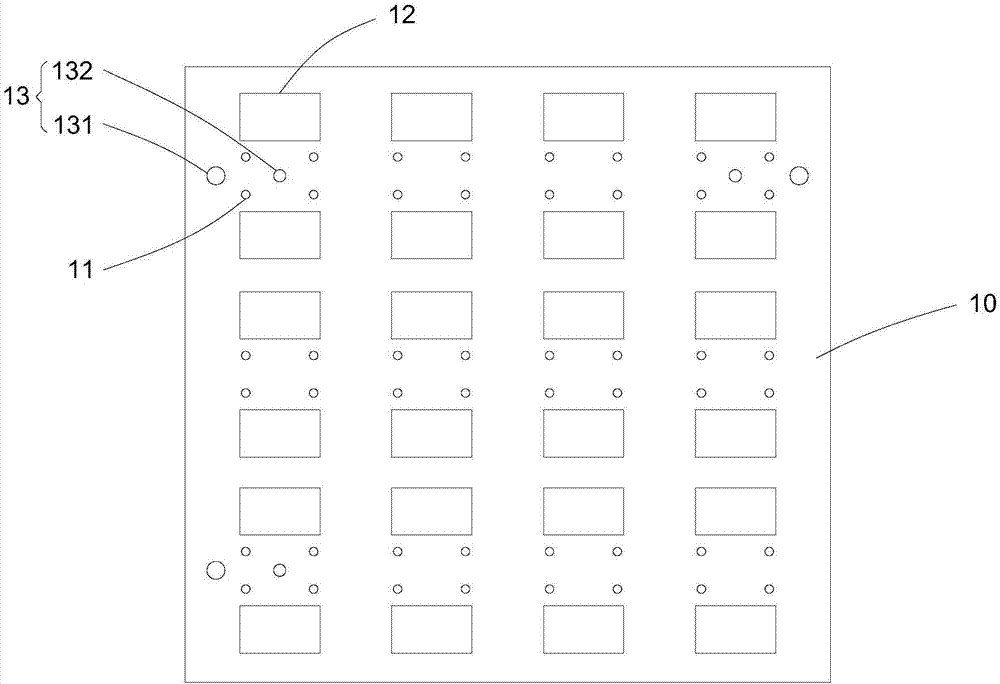

[0028] refer to figure 1 , figure 2 .

[0029] The embodiment of the present invention discloses a PCB tolerance plate structure, including a PCB substrate 10, on which are provided n sets of positioning holes 11 and n PCB line units 12, each set of positioning holes 11 corresponds to a PCB line unit 12, and the PCB substrate 10 10 is also provided with a reference measurement hole 131 and a solder mask alignment post 132, the solder mask alignment post 132 is located on one side of the reference measurement hole 131, and the thickness of the solder mask alignment post 132 is greater than or equal to the thickness of the PCB line unit 12.

[0030] After obtaining the PCB line unit 12 and the solder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com